The first autumn cold came unnoticed, and if your apartment or summer house became uncomfortable in the autumn, you should carefully look at the front door and windows - most likely, you will have to do their warming. We won’t touch the windows now, we’ll talk about the door, because it is here that the most problems occur. Especially if the door is wooden and has served for many years.

Insulating a wooden entrance door is not as difficult as it might seem at first glance: the presence of a simple tool and more or less stable handling skills, your personal desire and our advice will help correct the situation and adequately meet the cold winter.

So, there are only two ways to insulate the front door:

- Sealing the door frame in the places where the door leaf fits

- Door leaf insulation with thermally insulating materials.

Doorway seal

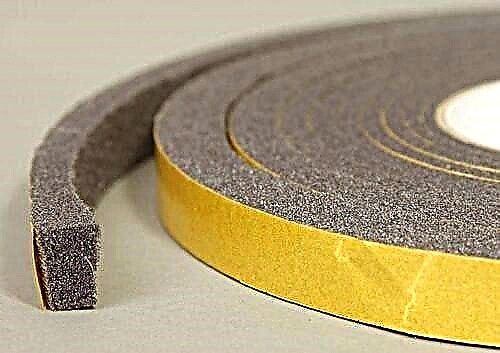

To seal the doorway, you will need to purchase a special rubber seal. Such a seal in the form of a tape rolled up into a roll is widely available and inexpensive, has an adhesive base on one side, which greatly simplifies its installation.

Before going to a hardware store or to a market, you should measure your door around the perimeter, the length of which will correspond to the length of the insulation purchased. Pay attention to the width of the folds: the folds are the place where the door leaf adheres to the frame, and it is obvious that the width of the insulation should be similar or slightly less. Try to determine the width of the gap gaps - the sealing tape due to its thickness in a compressed form should completely cover the gap.

Having the results of simple measurements on hand, you can correctly choose the rubber seal, which is very easy to install. We seal the doorway in parts - the upper part along the width of the door, having previously cut off the corresponding piece of tape, then the vertical sections along the height of the door and, finally, the lower part. To stick a strip of insulation, you need to gently press it with the adhesive side to the seam part, gradually removing the protective paper strip. Make sure that the sealant lies flat, without distortions, along the entire length.

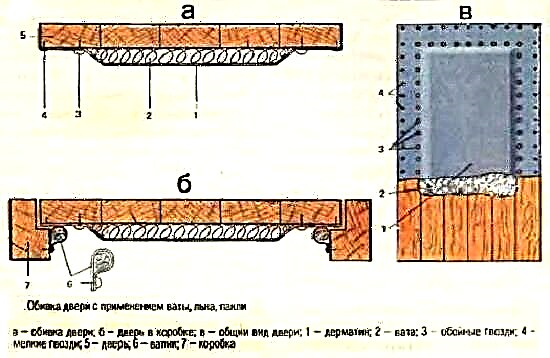

As, frankly, dubious, an alternative to a special rubber sealant, if it is not possible to purchase it, use the "grandfather" method in the form of a strip of dermatine folded into several layers, which is carefully beaten with cloves every 10-15 cm.

Door leaf insulation

As for the insulation of the door leaf itself, it is possible to carry out internal insulation (disassembling a door with a hollow structure and filling its internal space with heat-insulating material - polystyrene foam or mineral wool) and external, which we will talk about in more detail.

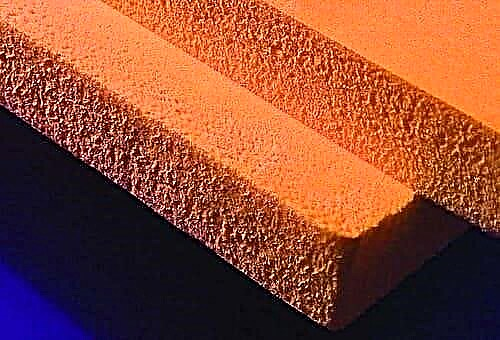

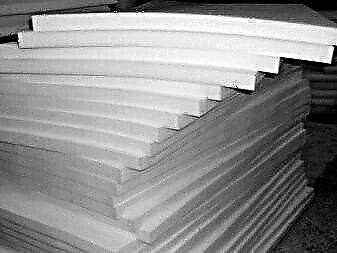

As a thermally insulating material, either polystyrene (foam) sheets or soft materials are used - cotton wool, foam rubber, mineral wool or isolonwhich are then covered with dermatin or leatherette. Of the listed materials, cotton wool and foam rubber are the least desirable since they absorb moisture and become a breeding ground for harmful bacteria, while foam rubber also breaks down over time.

Mineral wool has the only drawback - it gradually sags, deforming the initial layer and violating the uniformity of volume, everything else is good.

Isolon is a modern synthetic material that provides maximum thermal insulation with a small intrinsic thickness. Isolon in all senses is good and can be recommended without any conditions and specifications.

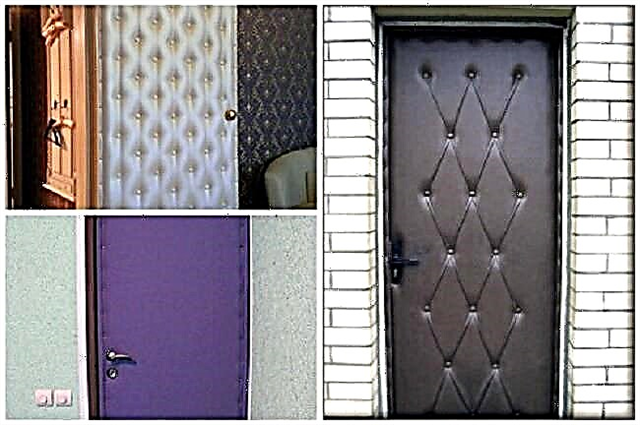

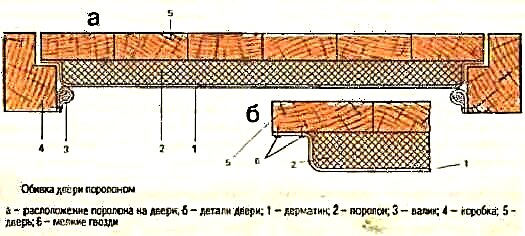

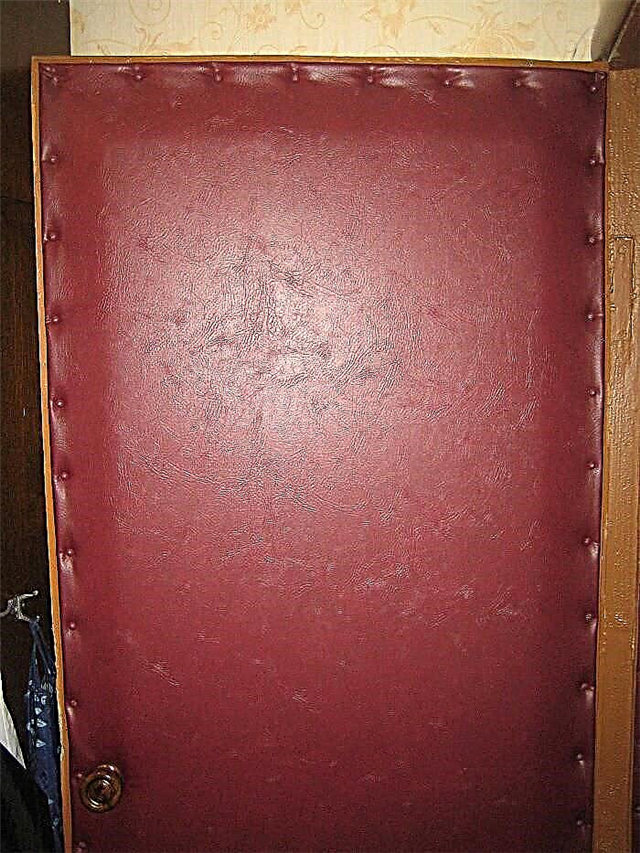

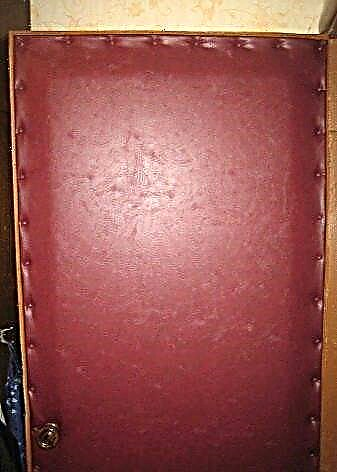

Upholstered door - a familiar method for many people to warm and decorate the front door, which used to be an indicator of the prosperity and high social status of the apartment owner. Today, this method has not lost its relevance, except that it is now available to almost everyone. Both individual materials and standard sets are on sale, consisting of insulation, upholstery material and decorative carnations, sometimes there are materials to create rollers for laying around the perimeter of the door.

Step 1. Remove the door leaf from the hinges and lay on the goats or stools.

Step 2. We place a thermally insulating material on the insulated surface. In order to prevent the sheet (or sheets) of the insulation from being dislodged during the subsequent covering with dermatin, first apply a sufficient amount of glue (PVA, “dragon”, “liquid nails” or other suitable adhesive) to the door surface and let the insulation stick well.

ATTENTION: the size of the insulation must be less than the size of the door by 1 cm on each side, and if upholstery of the side adjacent to the loot is made, one centimeter must be retreated from the edge of the door leaf of a tightly closed door, otherwise it simply will not close later.

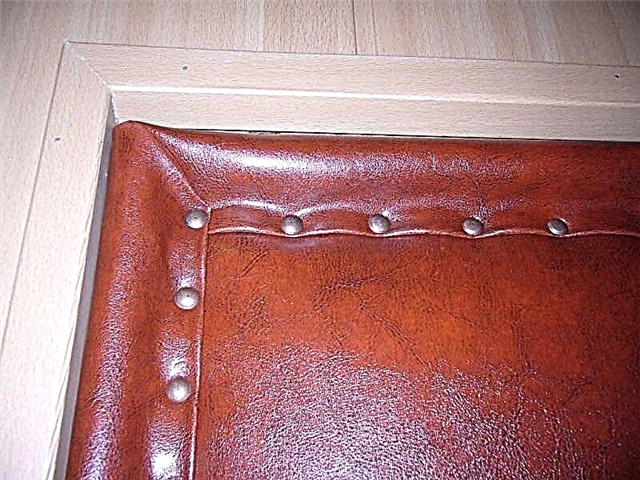

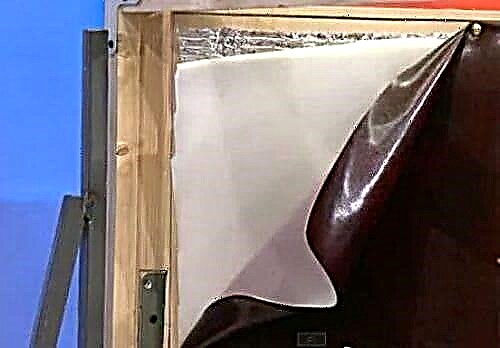

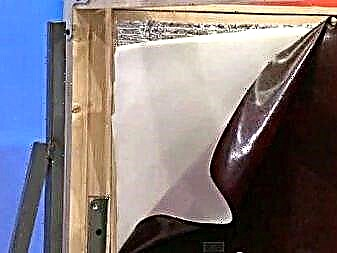

Step 3. We tighten the door with a heater with finishing material - dermatin, leather substitute, etc. To do this, you need an assistant who will monitor the uniformity of the tension of the canvas, preventing the occurrence of wrinkles and distortions. Begin from the top of the door. Tuck the edge of the material evenly inward to the required width and attach with special decorative studs, gently nailing them at the same distance. Then, observing the uniformity of tension, we beat the dermatin on the right and left sides, gradually moving to the bottom. Finish the upholstery at the bottom in the same way.

Pay attention to the part of the door where the handle and the mortise lock are attached (previously removed): in this part, it is necessary to cut the right amount of heat-insulating material used, also observing the "rule of one centimeter". Replaced handle and lock will serve as additional fastening of the upholstery. If a peephole is installed in the insulated door, mark its exact location before dismantling it and then return it to its place using the previous recommendations.

Foam insulation - a slightly different method, having two main varieties:

- gluing a polystyrene sheet (polystyrene) previously covered with dermatin using liquid nails to the surface of the door leaf,

- the construction on the door surface of a wooden frame with additional stiffening ribs, inside of which well-fitted pieces of foam are placed, followed by lining with a lining or laminated fiberboard.

The second method, of course, is preferable, however, it can significantly increase the total weight of the door leaf, and therefore the load on the door hinges, therefore, an insertion of an additional sing is recommended.

Since polystyrene is not a material harmless to human health, it is recommended to heat the door using it only from the outside, while for the inside, preferring the “soft” method described above.

As you can see, the process of warming the wooden entrance door of a house or apartment is a simple and affordable process for most. In addition, the described methods are cost-effective. Therefore, without waiting for the onset of real cold weather, arm yourself with our advice and get down to business: everything will work out!

How can you insulate the front door

The guarantee of future comfort depends on the selected material, for the sake of which warming was started. And if several decades ago only felt, foam rubber and dermantine were available, today there is much more choice. And here is what manufacturers offer:

- Mineral wool

- Styrofoam,

- Isolon

- Styrofoam.

Mineral wool, like polystyrene, is most often taken as the basis for insulation for metal door leafs. Both materials perfectly retain heat indoors and are not affected by microorganisms. Mineral wool is also worth noting because no rodents will spoil this insulation.

Mineral wool absorbs moisture

But these materials have some usage restrictions.

Polyfoam belongs to the category of combustible heaters, so its use for working with wood is possible only when processing with special compounds. And the “disease” of mineral wool is subsidence. Over time, the lining may be in the lower part of the canvas and cease to retain heat. In addition, mineral wool accumulates moisture inside itself, which adds weight to the entire structure. Therefore, such material should not be used for insulation of a bath or sauna.

The use of the isolon is more justified for achieving the goal of heat retention. This material is made on the basis of foamed polyethylene, which gives it minimal thermal conductivity. The advantages of the material include the fact that 10-15 mm thick cloth will be sufficient for work. This allows you to maintain an attractive appearance of the door leaf without thickening it and without making it bulky.

Isolon has low thermal conductivity

Expanded polystyrene has excellent performance. A door thus insulated will become a reliable and safe barrier between a warm house and a cold street. Among the advantages of expanded polystyrene, its incombustibility should be highlighted. When a flame occurs, it will gradually disappear on the surface of the material.

For inexpensive insulation you can always use foam rubber.. The material is convenient in all respects and will become a real find for a beginner home master. Foam rubber will forgive the mistakes made and allow them to be painlessly corrected.

Tool

It is impossible to do the work without a suitable tool kit. To create insulated wooden entrance doors you will need:

- Tape measure and pencil,

- Stationery knife,

- Hacksaw,

- Hammer,

- Screwdriver

- Level rail or metal meter,

- Installer or nail puller,

- Construction stapler.

Tools and trim needed

If necessary, this set can be expanded, but for most operations it will be quite enough. It should be noted that the hacksaw is easily replaced by an electric jigsaw. This tool allows you to do the job with the same quality, but much faster. And if the house does not have a screwdriver, then you can take a simple drill. The main thing is that she has a reverse, which will allow you to unscrew any screw or screw if necessary.

In addition to the tool, it is necessary to prepare the casing material. For most door leafs, it will be sufficient to use faux leather, which has an attractive appearance. This material has good characteristics and wear resistance, so the canvas does not need to be repaired for a long time.

And if you like to do everything with your own hands, then we recommend you instructions on how to make an entrance wooden door.

Preparatory work

To perform the insulation of the door leaf, you should go step by step, stage by stage. This approach allows you to achieve a good result and eliminate errors. And first, preparatory work remains to be done.

So that nothing interferes with the work, you need to remove the door leaf. This is done by mounting or nailing.. It is enough to pry the canvas from below and it will rise from the hinges. If the rotary axis is slightly rusted, then it must be lubricated with machine oil. After that, in small translational movements, you can stir up the loop and remove the door leaf.

When the door is outside the box, it is necessary to remove all available elements from it. Hinges, handles, peephole and lock neatly unscrew and retract to the side. If the door is not made only of wood, then it is necessary to remove the sheet of the inner lining in order to gain access to the interior space of the canvas.

Cutting and laying insulation

The next step in the insulation of the door leaf will be the laying of material that will make it warmer. To do this, you need to arm yourself with a clerical knife. Thermal insulation is cut along the length and width of the canvas so that there is no empty space. If the door is a frame with voids, then they need to be filled with insulation.

The insulation fits snugly between the bars

All pieces must be firmly inserted between the bars to prevent the formation of cold bridges. At the same time, the material should not bubble, which will indicate an excessively large supply. In this case, it is worth a little cut off excess material. As soon as everything is fitted, you need to fix the insulation with brackets. Quickly and efficiently, this allows you to make a construction stapler.

New door trim

The next step will be upholstery prepared wooden doors. For this purpose, you can use soft materials such as skin substitute or dermantine. The upholstery fabric is cut with a margin of at least 10 cm in length and width. This is necessary for bending the material, which should have some thickening around the entire perimeter of the door leaf.

As a finishing material, you can use dermantine

It is best to fix dermantine on special nails. They have a large decorative hat, which gives the skin a more attractive look. Also, you can put copper wire on the nails. If you pull it, you will get additional fastening for both insulation and exterior decoration.

An analogue of soft materials is MDF. This type of finish is used for frame paintings. In this case, each panel is mounted on a kleimer, and nailed along the perimeter with nails.

Installation of hinges and accessories

When the canvas gets a new look, you need to install the removed accessories in place. The hinges should occupy their nests exactly as they were installed before starting work. The seat for the lock must be carefully cut so that there is no damage around the door trim.

If necessary, insulation can be combined with the replacement of the lock on the front door.

The insulated door is mounted back

Seal installation

Installing frost-resistant insulation on the door leaf is only half the battle to eliminate the penetration of cold air into the living space. Even with the door closed, a small gap remains between it and the frame through which the cold will penetrate. Eliminate drafts - the next task for the home master.

To perform this work, you should choose the optimal type of seal. Today, manufacturers can offer the following types of this material:

- Foam Seals,

- Silicone seals,

- Rubber seals.

The first type of seal allows you to quickly and inexpensively solve the issue with drafts. It is ideally suited for the doorway of a structure such as a summer residence, where there is no high intensity of opening and closing doors.

Foam sealant - inexpensive, but also short-lived

Using a silicone sealant for doors will allow you to get rid of drafts for a longer time than the foam analog can do. The shape of the product guarantees a tight pressing of the canvas to the box, which will not allow the air masses to move inside the room.

The best option is a rubber seal. Due to its characteristics, it allows you to get a warm opening for a long period, even with the most intensive use. In addition, the variety of forms of this product makes it possible to install it on all types of door blocks.

For intensive use of doors, a rubber sealant is used.

Having chosen the desired version of the seal, it remains only to install it in place. There are two main mounting options:

- Using an adhesive strip.

- Using a harpoon in a groove.

The fastest way to install a new seal on the door is to use self-adhesive products. But this type cannot please durability, therefore many experts recommend harpoon fastening in a groove.

Choosing a small groove in the quarter without dismantling the boxes will be quite difficult. Therefore, it is allowed to carefully nail the seal with small cloves. Mounting must be done in the corner of the quarter. This will allow the panel to take its position in the door block without difficulty and provide reliable protection against draft.

Korovin Sergey Dmitrievich

Master of Architecture, graduated from Samara State University of Architecture and Civil Engineering. 11 years of experience in design and construction.

When to insulate?

Wood has low thermal conductivity, but the disadvantage of the material is its response to changes in humidity and temperature. The door block is cracking, swelling, warping and even cracking. There are three main reasons that signal the urgent need for insulation at the cottage of a wooden door:

- Education cracks between the box and the ends of the walls of the opening. Initially, during installation, all gaps are foamed. Foam is a good insulation, but loses its properties over time. Faster destruction occurs from the side of the street if platbands are not installed. Foam deteriorates from exposure to the sun. Another reason for the cracks is the skew of the ore.

- Education slots between the box and the sash. The most common defect of a wooden entrance door is due to poor wood, poor installation and long-term operation. Often the owner becomes the culprit when he cuts the swollen leaf so that it closes better. After drying, the product decreases in size, a gap forms.

- Wear insulation. Each heat-insulating material is selected taking into account operational requirements. If they were not initially observed, improperly selected insulation loses effectiveness. For example, mineral wool quickly coalesces, and due to dampness it decreases in volume.

You need to insulate any old wooden door, as well as a thin casement.

Which insulation is better to choose?

To make an insulated wooden door with your own hands, you will need a heat-insulating material, as well as material for the upper decorative finish. The sealant closes the gap. When the question arises, how to insulate a wooden door in a private house, pay attention to the following materials:

- Styrofoam better to use as an internal insulation of wooden entrance doors. Plates can be sheathed from the side of the room.

- Foam rubber It is considered the most common insulation, which is covered with artificial leather on top. Porous material allows you to create a volume effect. Foam rubber loses over time crumbles crumbs.

- Minvata it doesn’t burn, it has good thermal insulation properties, but it cakes quickly. When exposed to moisture, it accumulates moisture. Under weight it slides from a vertical surface.

- Polyethylene foam - Isolon in structure resembles foam rubber. The material is characterized by the best thermal insulation performance, long service life. Isolon does not tolerate long exposure to direct sunlight.

- Polyurethane foam applied by spraying, firmly adhered to wood, penetrates into all cracks. The disadvantage is the inability to perform work without special equipment.

- Expanded polystyrene resembles polystyrene foam, but has improved characteristics. The material has self-extinguishing properties when exposed to open flame.

When choosing a heater for the doors of a wooden house, it is important to consider the thickness of the material. Thick layers will make the sash heavier and create an obstacle to normal closure. Thin is useless. You need to find a middle ground between these two parameters.

Types of door frame seals

In addition to thermal insulation, you will need a sealant to seal the cracks around the perimeter of the canvas. It is a tape characterized by thickness and material:

- Foam Strip fixed due to the adhesive base. The sealant wears out quickly during the season.

- Silicone strip resistant to moisture, elastic. Over time, begins to stick, torn pieces.

- Rubber rubber a sealant for wooden doors will last for many years. The tape is resistant to wear, moisture, mechanical stress.

- Thermoplastic - the best in wear resistance, but difficult to install.

- Polyurethane strip sticks due to the sticky base. The characteristics are not inferior to a rubber seal.

Thermal insulation cannot be made without decorative finishes. Usually, the insulation is covered with artificial leather. They are fixed with furniture nails with a wide decorative hat. From the inside, the canvas is sheathed with laminated MDF panels. The leather trim looks beautiful, but the material is very expensive.

How to insulate a wooden door?

Begin warming a wooden door with preparatory work:

- loose loops are secured with new elongated self-tapping screws,

- if thick heavy insulation is used, install an additional loop,

- eliminate box distortions, blade defects,

- check the condition of the seal around the perimeter of the door pipe at the junction with the walls,

- change broken accessories: lock, handles, inspection eye, latch.

After eliminating all the defects, the installation of insulation on wooden entrance doors begins.

The question often arises whether vapor barrier when warming wooden doors? When arranging the mounting seams of the door block - needed. The gap between the box and the wall is sealed with foam. To prevent thermal insulation from spoiling, PSUL tape is closed from the seam from the street. From the side of the room, the foam is destroyed by vapors. To protect the seam, seal with vapor barrier tape. A vapor barrier may be required for the product if it is installed in a damp room, and mineral wool serves as thermal insulation.

What are they for?

Entrance doors cause drafts and cold air to enter the premises. This leads to an increase in heating costs, and also leads to mold. Very often, such structures were installed on the balcony, where the same problems arose.

The solution to this problem is insulated door leafs. Outdoor models withstand temperature extremes in winter, and also perfectly retain their original parameters. Therefore, many owners often change old products for this product.

A warm door allows you to solve several problems:

- The product minimizes heat loss. This makes it possible to maintain the optimum temperature inside the house and at the same time reduce the amount of fuel for heating it. This is achieved due to several layers of insulation, which eliminates almost all the cracks.

- The door leaf has high soundproofing parameters.. External sounds and smells will not enter the house. This will create an optimal microclimate inside.

- A warm door does not allow condensation to form on its surface. This is achieved due to the fact that there is no temperature difference. Water does not destroy the surface of the canvas and the walls where it settles.

This type of door can be used in both private and multi-storey buildings. High-quality models are made of strong wood species, which are distinguished by durability and unique decorative characteristics.

Structure

Insulated wooden doors have been popular for a very long time. They perfectly withstand frost, and also withstand temperature extremes. One of the drawbacks of this product is that the wood must be constantly looked after to prevent the occurrence of large cracks.

This design consists of several main layers:

- Frame. They are made of solid wood or of bars of a certain thickness, which are sheathed with MDF or chipboard sheets. The first version of the door leaf is of high quality and is the main one on the market.

- Sealant. It is attached over a wooden canvas - with glue or furniture nails. To give beauty from above, all this can be sheathed with decorative fabric. All these materials are selected for the specific climatic conditions of the zone where the house is located. This minimizes their destruction and ensures a long service life.

Please note that the insulation can be located both on the outside or inside, and cover both parts. The latter option is practiced quite rarely, because quality-insulated doors on one side can provide the desired effect.

Today there are door models in which the seal is located inside a wooden box. This structure provides better insulation, and also preserves the unique design of wood. The cost of such products is much higher than the price of structures that are upholstered with insulation.

To minimize heat loss, the sash is made with a slight lunge. It is intended to close the gaps between the box and the canvas. Many options are complemented by special seals that prevent the occurrence of holes in the closed state of doors.

To make the door original, decorative trim is placed on top of the trim.

They are made from sheets of MDF or veneer of various tree species (oak, beech, hornbeam, pear, walnut and so on). Their shape can be different, which allows you to give volume and beauty. Some types of insulated doors can be supplemented with inserted glass, but such designs are already much more expensive than conventional counterparts.

What is better to insulate?

Today, wooden doors are used in many private houses or apartments, but at the same time they do not have sufficient thermal insulation characteristics. To warm the balcony system or linen in a country house, you can use several types of materials, their set:

- Foam rubber. It is a foamed polyurethane that perfectly retains heat. Today on the market there are several types of foam rubber, which differs in density and thickness.

For door trim, use a set of material with a thickness of at least 30 mm. If winters are cold, then this parameter can be increased. Rollers are also made from it, which are installed around the perimeter of the canvas to prevent the movement of cold air.

- Isolon. The best option would be an isolated variety of this product. It is covered with foil on one side, which reflects heat more carefully. The thickness of the sheets of isolon can also be different.

Please note that the thermal insulation characteristics of this product are much higher than foam rubber. This allows you to achieve the desired results when using thinner sheets.

- Batting and felt. As heaters they were used earlier. Today, they are found less and less, as they quickly coalesce and lose their original parameters. Sometimes they are used as an additional layer - in multilayer insulation systems.

- Mineral wool. This material perfectly retains heat, and also does not burn and does not support combustion. But the sheets of cotton wool have a significant thickness, which will affect the external dimensions of the door leaf. This material can accumulate moisture, which leads to its rapid caking. To eliminate this factor, mineral wool is placed between the layers of the insulating film.

- Polyfoam (foam). One of the cheapest and most affordable heaters. This substance retains heat well, but can also accumulate moisture. Therefore, it should be isolated, as is the case with mineral wool.

One of the disadvantages of this material is that it burns perfectly. At the same time, it also releases harmful substances into the air, which have a very negative effect on the human body. There are several types of polystyrene on the market, which allows you to choose it both in thickness and density.

- the cloth. This material is auxiliary, as it is used for decorative sheathing of previously considered heaters. Today, for such purposes, both dermatin and natural skin are used. They are another additional layer that increases the level of thermal insulation.

- Rubber. This material is used as an auxiliary. Seals are made from it, which are attached to the door leaf. This eliminates the occurrence of drafts that form in the cracks. Today on the market you can find many types of seals, which vary in shape and installation method.

Practically any of these materials can be used in a rural house. The main thing is to choose the right layer thickness, which will provide the optimal level of thermal insulation.

How to do it right?

Warming of a wooden door can be done with your own hands, it is quite simple. It is important to understand that ready-made structures can only be sheathed outside the canvas. The algorithm for implementing this procedure consists of several successive steps:

- Dismantling the door leaf. This will greatly simplify its upholstery - both inside and out (relative to the room).

- Mounting the heat insulator on the surface of the canvas. The material is fixed in several ways, it depends on the material used.

- Sheathing the sheet with decorative cloth. It not only decorates the surface, but also additionally hold the heat insulator.

- Packing gaskets. Such materials are used if it is necessary to provide complete thermal insulation. To do this, the seals are mounted around the entire perimeter of the door leaf. It is important that when closing they are tightly connected, eliminating the occurrence of gaps.

Some experts recommend installing rollers with seals. These designs are small foam cylinders that are wrapped in the same fabric as the door. They are attached to the box so that they cover the slots. They are located on the side where the door does not open.

As for the door trim, it can be carried out in several ways, which depend on the chosen insulation:

- Sheathing. This is the easiest way, it is quite easy to handle this work yourself. For this, foam rubber and dermatin are often used. Foam rubber is placed on the surface of the canvas, and then cover it with an upholstery fabric. After that, the material is nailed to the tree with the help of decorative nails. Attachments are selected individually, the main thing is that the fabric is held on the surface of the doors. Please note that this technology can be used not only with foam rubber, but also with isolon, mineral wool. It is important to select high-quality fabric upholstery that will hold this system.

- Frame finish. So you can insulate with almost all types of insulation. The technology involves the construction of a rigid frame around the perimeter of the canvas. As materials use wooden planks of a certain thickness. They are screwed to the door with self-tapping screws or nailed. To ensure the optimum level of support for the insulation, several horizontal partitions from the same bars should be nailed.

Such frames can be built on both sides of the canvas. Such a dual-circuit system will provide a better level of insulation.

After that, insulation sheets are laid inside the frame. It can be both mineral wool and polystyrene. Fixation is carried out using liquid nails or a stapler.

Today, many doors are made using Finnish technology, which involves several layers of different insulation. This approach can also be used with independent insulation of the structure. Here you can combine foam, mineral wool and polystyrene.

The process ends by attaching the upper decorative lining to the frame made. The simplest option is a sheet of chipboard, which is cut to the dimensions of the door. Sometimes you can use metal sheets or other similar products.

The quality of insulation depends not only on the structure of the door leaf. Slots can also occur at the joints between the wall and the box. This is due to the fact that the holes are filled with foam, which eventually loses its properties and cracks. Sometimes the box itself can also sag, which leads to the formation of gaps.

To make a wooden door truly warm, all of these factors should be eliminated. To do this, find all kinds of holes and close them up. Sometimes cold can penetrate through damaged accessories, so it is important to pay attention to its condition. If it is in poor condition, it is better to replace it with new elements.

Insulated wooden doors are unique designs that significantly reduce heat loss. It is important to give preference to quality products manufactured by well-known companies.

You can find out how to make a warmed entrance wooden door with your own hands by watching the following video.

Installation of a sealant on a door frame

The first salvation from heat loss is the installation of a seal on a wooden door to eliminate gaps between the sash and the frame. The tape is selected according to the thickness corresponding to the size of the gap. A thin strip is useless, and a thick one will become an obstacle to the normal closing of the canvas. Installation of the seal consists of the following:

- Measure the gaps between the sash and the box, select the thickness of the tape.

- A self-adhesive sealant is glued into the groove around the perimeter of the ore.

- Silicone tape is fixed with the staples of a building stapler.

If the size of the gap around the perimeter of the door block is different, which often happens during deformation, the groove is widened and deepened in the box. The edges of the canvas are grinder. A two-layer or three-layer tape is glued to a new groove.

A properly glued seal should fit tightly around the edge of the sash around the entire perimeter and not interfere with its free closing.

Roller sealing

The joint along the perimeter of the door frame can be insulated with dermatin rollers with foam inserted inside.

- Measure the length of all sides of the sash. According to the results, four strips 100 mm wide are cut out of dermatin.

- The strips lean against the edge of the sash upside down. Near the edge of the door leaf, the dermatin is fixed with a stapler.

- Inside each strip, thick foam is laid, a roller is formed.

- Fasten the second edge of the dermatin with a stapler.

The door block becomes more beautiful, and all the gaps are hidden under the rollers.

Cloth insulation

To maximize the insulation of a wooden door, do-it-yourself way of double-sided thermal insulation. The sash is faced on the outside and inside. From the street, the thermal insulation is covered with a material resistant to aggressive weather conditions. To insulate the front door from the inside, foam rubber and artificial leather are most often used. Insulation of a wooden door> with dermantine with your own hands occurs in the following order:

- For the convenience of work, the canvas is removed from the hinges, freed from the old insulation, handles, locks and other accessories.

- A fragment is cut out of the insulating material, larger than the dimensions of the sash. It is good if about 100 mm of foam rubber hangs on each side.

- Insulation on the edge of the door is shot with staples. The hanging ends are cut with scissors.

- Foam is covered with artificial leather on top. From the hanging edges, rollers are formed and fixed with furniture nails. The general plane of the canvas is decorated with a pattern. It turns out after nailing. Soft foam between the wide hats forms a beautiful bulge. Between the fasteners, you can stretch the wire or stitched with a tubular strip of dermantine.

At the end of the work, install all the accessories and hang the insulated product on the box.

If foam or polystyrene is chosen for the insulation of the door block, MDF is usually applied to the final cladding. The flap increases in thickness and weight. The door block is further reinforced with hinges. The frame forming the cells is nailed to the surface of the web of slats. Foam slabs are tightly laid, and the gaps between the slats are blown with foam. MDF is fixed on top.

You can glue thin foam boards to the door leaf without making a frame. For decorative use artificial leather.

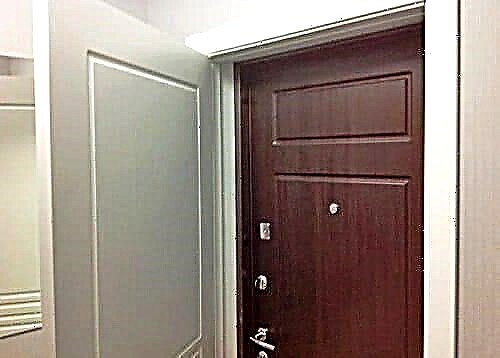

Installation of double doors

A good way to warm the house is to install a double entrance door. Due to the formation of air space that separates the room from the street, heat is retained. The disadvantage of this design is the reduction of space.

A threshold is set for the indoor unit. The insulation is additionally laid on the slopes between the doors. There are designs where two wings are hinged on one deep box.

Warming the front door, we must remember that moisture affects the canvas from the side of the street. Processing from impregnation, staining with paint or varnish will help protect against dampness. A good waterproofing creates drying oil.

Types of wooden entrance doors

Entrance zone - the visiting card of the owner, an indicator of his status and taste. The choice of an insulated wooden door for a country house needs special attention. The design should be not only strong and durable, but also beautiful.

Street wooden blocks are very diverse:

- rectangular

- arched

- single or double leaf,

- glazed or deaf,

- with side inserts or upper transoms.

To improve the thermal insulation of rooms, double doors are often installed, cutting off the flow of cold air and additionally protecting the house from breaking.

The front part of the structure is made with panels or smooth. The insulation is placed inside the frame, and the casing is fixed on top.

The surfaces of warm wooden doors are painted, tinted, varnished, brushed, decorated with carvings, forged elements, decorative films or linings. The threshold and the lower part of the web are additionally strengthened with steel sheets or superhard fiberboard.

The design of the insulated door

In private homes, the door block is in contact with the street, exposed to rain, sun and frost. Street options are usually reinforced. Thermal insulation of the canvas with laying of 2-3 sealing loops is provided. To protect against hacking, special locking systems are installed, the eye is inserted. Use weatherproof materials, fittings and finishes.

The design of the insulated door made of wood should provide resistance to temperature and humidity changes, seasonal deformations, geometric stability, fire safety.

The door unit includes:

- A box with a thickness of at least 50 mm and a width of 80-100 mm.

- Canvas with a layer of insulation.

- Threshold and pretended slats to increase heat and sound insulation. When closing, they are superimposed on the sash.

- Platbands and extras for the design of the opening, eliminating the cracks between the box and the wall.

Modern technologies and finishing methods have so changed the quality of warm wooden doors for private houses that they are not inferior to metal security.

Tree

Entrance warm doors are made of solid wood or wood processing materials - MDF, plywood, OSB. They are combined with metal, plastic.

For solid wood canvases, coniferous or deciduous trees are used:

Wood of oak, ash, beech or exotics is dense and hard. Thanks to its resinous nature, pine is rot resistant. Solid structures are not cheap, so materials are often combined, veneered from a cheap wood with veneer of valuable species.

Heaters

For effective thermal insulation, materials with a low coefficient of thermal conductivity are used:

- Expanded polystyrene is a light, moderately combustible polymer obtained from foamed thermoplastic. The structure of closed bubbles creates a heat and moisture barrier. It does not rot, environmentally friendly. For insulation, 40 mm thick boards are used.

- Mineral wool - does not burn, is absolutely harmless, but is afraid of moisture. In the manufacture of the canvas, you need to take care of the vapor barrier of the material in order to avoid the occurrence of condensation and the deterioration of thermal insulation properties. The optimum thickness of the insulation is 40 mm.

- Polyurethane foam - environmentally friendly, biologically inert, with very low thermal conductivity. A layer of 10-30 mm is sufficient to insulate the outer doors.

Additionally, foil heat insulators are used, the metallized surface of which reflects infrared rays into the room.

Gaskets

Sealing materials are placed around the perimeter of the canvas and boxes to prevent heat loss through the cracks, as well as sound insulation.

These are tapes, cords or soft profiles made of elastic materials:

- rubber

- foam rubber

- polyurethane foam

- synthetic rubber

- silicone

- thermoplastic elastomers.

They are attached to glue or made in the form of self-adhesive products.

The most durable seals made of ethylene propylene rubber. They withstand large mechanical loads, operate in the temperature range of -50 .. + 50 ° C. Profiles of various shapes eliminate gaps up to 7 mm.

Hardware

Accessories for street wooden doors of a country house must comply with the conditions and mode of operation.

For hanging external paintings, loops with an anti-removable mechanism are used. When the shutter is closed, the protrusions and depressions of the device are combined, preventing the structure from moving in the vertical direction.

Hinges for external doors are larger than for interior doors, as they are designed to absorb a greater load. On average, the weight of a wooden cloth with insulation is 75-90 kg. Therefore, mortise options are used, in which the weight of the sash is perceived not only by self-tapping screws, but also by the edge of the landing socket.

Optionally attach the heavy block to 2 removable hinges.

Well, if the design of the loop does not interfere with the laying of the sealing circuit. Otherwise, it will have to be torn.

Manufacturers of wooden insulated doors

Warm wooden front door - the product is almost always exclusive. Manufacturers develop models, attracting the customer with an original design, the ability to choose the material and color of the finish, provide warranty service.

These are the companies:

- Medver Moscow,

- Vympel-M LLC, Kirov,

- "NEW DOORS" Kirov region,

- LLC "Gambit", Yekaterinburg,

- LLC "TSHI" St. Petersburg,

- Doors Profit LLC Pyatigorsk.

Many manufacturers of metal blocks have the technical ability to make wooden entrance doors for private homes. Demand for them does not fall, products are in demand, so a number of companies offer this range as well.

Independent insulation of a street door

Wood has a porous-fibrous structure and, unlike metal, does not conduct heat well. But if the finished unit is not initially insulated, dried out or freezes, reduce thermal conductivity and There are several ways to eliminate drafts:

- lay the insulation inside the canvas,

- sheathe the surface with insulation

- seal cracks, junctions.

This work is not difficult, even one person can do warm wooden doors with his own hands.

Thermal insulation of the canvas from the inside

To place a heater in the canvas frame, you need to remove it from the hinges and dismantle the casing.

Such an operation can lead to material damage, therefore, a new cladding should be prepared in advance.

Warming is good to combine with the simultaneous restoration of the door block.

Moisture-resistant materials are used for interior decoration:

- plastic panels

- skin and its substitutes,

- processed wood, lining,

- MDF.

The heat insulator is cut to the size of the canvas and put into the cells between the bars of the frame.

For insulation use:

- Styrofoam,

- polystyrene foam

- dense mineral wool of grade no lower than PM 40,

- foam rubber

- Isolon.

The blanks are inserted into a spacer or glued with liquid nails.

Mineral wool should be wrapped on both sides with a vapor barrier diffusion film. It will not allow condensation to accumulate inside the material.

It remains to complete the decoration and return the canvas to its place.

Insulation of the door surface from the inside

This method is used if it is not possible to dismantle the unit or remove the casing. The insulation is glued or stuffed to the surface. As thermal insulation, you can even use an unnecessary blanket.

This method is used if it is not possible to dismantle the unit or remove the casing. The insulation is glued or stuffed to the surface. As thermal insulation, you can even use an unnecessary blanket.

Cut out a rectangle of soft material with dimensions 10 mm smaller than the canvas, firmly fixed. Finishing dermatin is applied from above, straightened, nailed with decorative nails.

Ready-made kits for insulation are available for sale. They are cut for blocks of standard sizes.

Gasket installation

Wood is a living material. He is sensitive to changes in humidity. The gaps between the blade and the box are a frequent defect that occurs during the operation of wood.

Wood is a living material. He is sensitive to changes in humidity. The gaps between the blade and the box are a frequent defect that occurs during the operation of wood.

Eliminate it by installing sealing tapes or profiles. On one side of the products, as a rule, glue with a protective film is already applied. When laying it is removed, press the seal to the vestibule of the canvas, gradually passing along the perimeter.

To enhance the effect, the same thing is done on the box. The tape is laid at the junction of the door to the selected quarter. The better the sealant, the longer it will last, the more reliable it will protect the room from heat loss.

Conclusion

Wooden entrance doors are the best alternative to metal. As a rule, the technology provides for thermal insulation in the production cycle. If the block was not prepared for the winter, you can do it yourself. It is enough to sheathe the canvas with insulation, and lay a sealant along the contour.