The advantages of metal shelving

The main requirement for metal shelving in the warehouse is ease of storage and considerable savings in renting space, for retail shelving so that the buyer wants to buy the goods. But at the same time, commercial furniture should have such properties as compactness, efficiency and durability.

In the case of metal furniture for retail space, we get a full combination of these properties - metal shelves can withstand significant loads, have high wear resistance and save storage space.

Supermarket shelves are usually made of metal, and this is due precisely to the optimal ratio of price and quality.

In addition, an additional advantage is the variety of sold forms - corner shelves, double-sided, as well as island shelves are provided for the buyer to choose.

The correct choice of the form and type of the rack will allow you to order the goods and be sure that the place in the store and in the warehouse will be used in the best way.

In addition, the trading equipment made of metal, due to the peculiarities of its design, allows the buyer to buy goods without distracting his attention from a potential purchase.

Disadvantages of metal shelving

Despite the obvious advantages of metal furniture, it has its drawbacks.

In this case, it is necessary to remember first of all that such racks do not tolerate improper installation, as well as experiments with the form - such designs are designed to hold a large load, their incorrect installation can lead to failure of the rack and, possibly, damage to the cargo, which was installed on it.

Also, often in his desire to order goods, an entrepreneur chooses a manufacturer whose products are not of high quality - and this also applies to commercial furniture. Failure of commercial equipment entails even larger consequences than simply damage to goods due to transportation or improper storage.

Obviously, the use of metal shelving for a store or warehouse is the most optimal solution.

But it should be remembered: regardless of the type of structures used, it is necessary to monitor the quality of the products supplied to you, check their correct installation on the retail (or warehouse) premises, and maintain the structures in working condition by regularly inspecting them for damage.

In the case of trading equipment and warehouse equipment, each ruble saved can cost you much greater losses.

We hope that the products from our catalog - metal shelving - in Grodno will help you in the rational use of retail space, provide the store with an attractive appearance, and give customers simple, visual and convenient access to goods.

We offer really high-quality and esthetic products at low prices.

In addition to metal racks, customers are offered other types of metal furniture, including archive and accounting cabinets, safes in a wide variety, file cabinets, locker rooms and other products.

Features

Metal racks are considered the best constructive solution for using free space in the garage. These products are durable, can withstand heavy loads, while the lungs themselves, due to which they can be easily moved from one place to another.

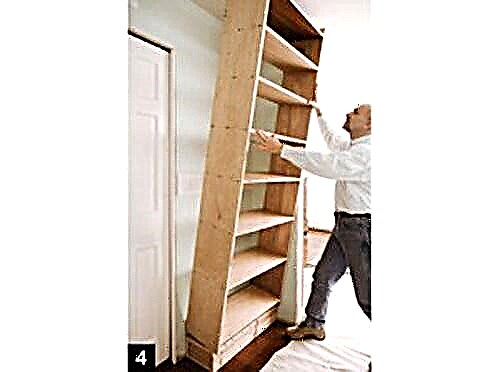

A big plus of metal shelving is their ease of assembly. This feature allows you to save time, and sometimes money, since you can assemble such a mechanism yourself, without calling experienced collectors for help. It is also convenient that you can adjust the height of the shelves, and in some models and change the distance between them. With this functionality, the process of placing and storing things is greatly facilitated.

Another advantage of metal garage systems is their long service life. The racks created from stainless steel, covered with a protective layer of dye, are not afraid of increased humidity, temperature jumps and exposure to chemicals or other means that are used in car care and repair. The racks will serve for many years, even if there is no heating in the garage, and a fierce winter rages behind the wall.

But the advantages of metal shelving do not end there.

- Practicality. On these racks you can place objects of different shapes, weights and designs, and what is very important - everything on the shelves can be easily reached.

- Increased technical and operational characteristics. In addition to durability, resistance to weather conditions, mechanical and physical influences, racks differ in environmental friendliness and fire safety.

- Versatility. In many models of shelving, it is possible to increase / decrease shelves, to make them solid or separate.

- Compactness. Thanks to metal shelving space in the garage is significantly saved - there is more useful area.

- Attractive design. If you paint or cover the rack with any other material, you can use this product in retail spaces or various exhibitions as a display case.

Thanks to these advantages, you can store in the garage all the most important tools and accessories for servicing the car, as well as various items that became crowded in the house (for example, conservation for the winter).

Metal racks usually have at least two tiers, the task of each of them is to store a certain type of product: car tires, wheels, tires, repair tools. As a rule, tires should be stored in a special way so that their service life is as long as possible: tires without wheels should be kept horizontal and with wheels in vertical position.

It is better when overall objects are at the bottom of the rack. So it will be more convenient to put and get them, and the canopy will not suffer from too much load. In addition, the space will not visually look too oversaturated.

Disadvantages

Despite the obvious advantages of metal shelving, they also have their drawbacks.

First of all, we are talking about the fact that such furniture does not tolerate improper installation, and also does not accept experiments with form. The design of the rack is designed to hold a lot of weight, improper installation can damage the unit and possibly even break it, and the load itself may suffer.

It is also not uncommon to buy a product of poor quality. In pursuit of savings, some buyers choose a manufacturer whose products can cause great doubt, but at this point many turn a blind eye, because the cost of the rack is quite tempting.

Such designs can cause unforeseen situations, and damage to the goods in this case may not be the worst option. Sometimes racks created with a violation of technical characteristics and not installed according to the rules fall, destroying everything around, and in the worst case they can even crush a person.

Rack design and types

Today, there is a wide variety of rack designs for installation in garages. Metal racks are considered the most convenient and functional. They can be assembled in a few minutes, just as quickly dismantled, moved and transported. In addition, collapsible structures can be easily adapted to the area of the room by adding or removing additional / extra modules.

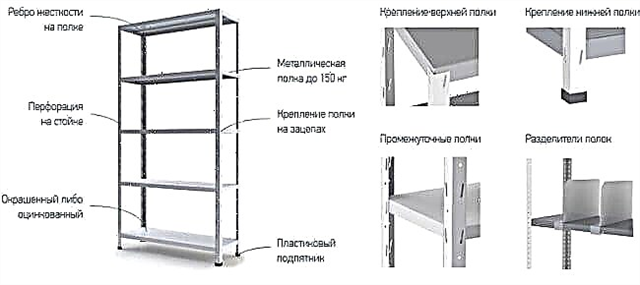

In rooms where there are large (cargo) vehicles, it is better to install a cargo type of shelving. Each shelf of such a product can withstand a load of up to 500 kg. This type of metal furniture is made of beams, racks and traverses, which are interconnected by hooks - no bolts are used in this embodiment of the product. Bottom installed metal or plastic base. Such collapsible structures are very reliable and durable.

If racks are installed to store a small number of items, then you can choose the ceiling type of structure. Each shelf of such a product can hold a weight of not more than 120 kg, which is quite enough to store tools and manual parts. Meanwhile, some firms produce ceiling racks with a much higher payload. Such units can be equipped with partitions, doors, containers, brackets and other auxiliary elements.

Such types of devices for storing things from metal as a hinged or floor rack are also popular with motorists. The first models are attached directly to the wall, hence another name - wall. As a rule, such racks are disassembled. They are easy enough to dismantle if there is such a need, and then it is just as easy to fix it back. The easy and time-consuming process of installing such products is their indisputable advantage.

There are certain rules for mounting wall structures, due to which you can avoid various possible inconveniences. Hinged racks are fixed exclusively to a load-bearing wall or to a surface with high strength. If you ignore this moment, the rack may not withstand the load, fall, making a terrible mess in the garage, damage something or permanently ruin it.

An important point that distinguishes hinged racks from other models is their inability to hold large loads. This means that heavy boxes and objects with a large mass can not be laid out on the upper tiers. For many consumers, this factor is negative and can be decisive in choosing a product.

Floor models are more popular with buyers, as they are practical and convenient to install and use. Usually floor racks can be disassembled, they can withstand heavy weight.

What to look for when choosing

Before buying a metal shelving for use in a garage, several factors need to be considered.

- First you need to decide what items will be stored on shelves, what sizes and weight they have. It is important to consider the material of the construction of the rack, its parameters, the method of fixation and installation. You need to pay attention to the shelves: there should be no visible defects on the product.

- Installation space also plays an important role. The best option is the area farthest from the garage door. With this arrangement, the motorist will be able to clearly see the area of entry into the room.

- Modern manufacturers produce racks of different materials (plastic, wood), but the most optimal and rational option is metal.

What should be a garage rack?

To reasonably talk about the selection criteria, for a start it would be nice to understand what requirements a garage rack should meet. It is fair to talk about the following characteristics:

- matching garage size. The main task of the rack is to help the car owner organize the storage system correctly. If things are scattered around the garage, then they will take up a lot of space, interfere with putting the car and serving it. On the other hand, the rack also should not restrict freedom of movement, so you have to solve a difficult task - to find a rack that would accommodate everything you need, but at the same time take up a minimum of space. If there are few things, then the task is simplified, but you can find a solution in any case. Fortunately, there are a lot of different design options,

Making an intermediate conclusion, we note that it is very important when choosing a rack in a garage to understand what size the structure will suit you, and where exactly it will stand. In order not to get confused and not make a mistake, make a plan on which the dimensions of the garage, the place for the car and the area intended for the garage will be indicated. Let you spend a little time, but significantly reduce the likelihood of error.

Types of garage racks

There is an opinion that the best, most reliable and proven rack for a garage is stationary. But besides him, there are other options, and they have their advantages. In some cases, the stationary model may even be inferior to competitors. So, weigh your requirements for the rack and choose the most suitable type:

- stationary rack attached to the floor, walls or ceiling, therefore it is considered the most reliable and durable. It consists of vertical racks, horizontal partitions and shelves. Shelves can be metal or wooden. If provided by the design, the shelves can be rearranged, changing the volume of the storage sections. If necessary, some shelves can be removed altogether, creating a place to store tires. For those who are going to store something quite heavy, this type of shelving is best suited. Typically, models are made of metal, but shelves in some cases can be wooden,

- prefabricated / collapsible - It is, rather, whatnots than full-fledged shelving. It is convenient that the master can dismantle such a rack at any time, transport it and assemble it again, but such structures cannot be called durable. However, if you are going to store only hand tools and small hardware, then such a rack will be enough for you. As a rule, products are made of metal,

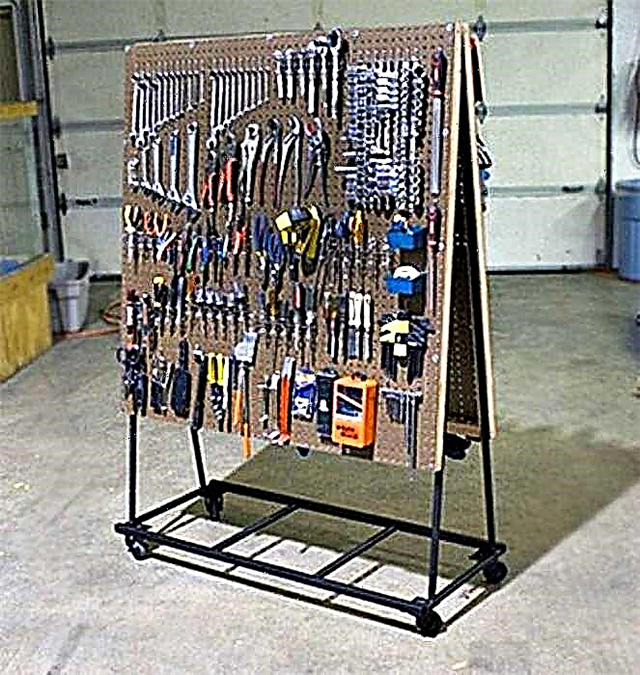

- mobile shelving differ in mobility. If during work in the garage the rack will interfere, it can be quickly moved to the far corner, and then put back. During car repair, the structure can be moved closer so as not to run after the right tool. It would seem an ideal option, if not for its lack of stability. Mobility is provided by the presence of wheels or rollers. It is their presence that does not allow the design to be so reliable as to withstand decent loads. It’s impossible to say that mobile shelving is bad, because in some cases their capabilities will be quite enough,

- island rack can be considered a special case of a mobile structure. They are designed for 2-3 shelves, have a small height, are equipped with wheels, although they can be without them. They withstand a small load, convenient for storing small things. The island rack on wheels helps a lot when repairing a car,

- rotating shelving - A rarity in our garages, but they are great for placing hand and electric tools, hardware. The rotation function provides the easiest accessibility to everything that is stored on the shelves of the rack. If in the garage you often do repairs, then you will like this kind of design. It is not necessary to replace it with a stationary rack - it can become an additional element in the organization of the storage system. There are models designed for floor and desktop installation. They take up little space.

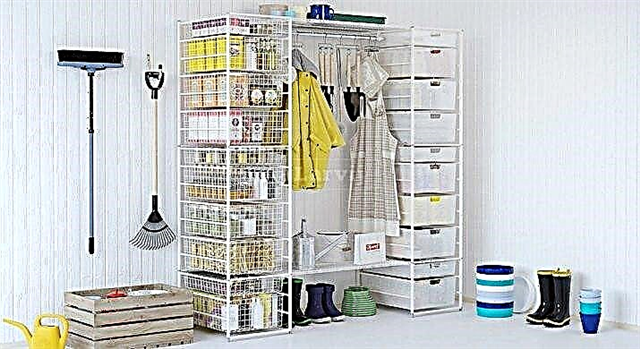

Separately, it is worth highlighting modular shelving, which are slightly different from the generally accepted concept of “shelving”. Like modular furniture, a modular shelving unit consists of several blocks.As blocks, not only traditional shelves mounted on vertical racks can be used, but also hinged shelves and drawers of various types, as well as systems such as rails, designed to hang inventory. Any storage system can be assembled from various blocks and, if necessary, it is easy to supplement it. Such systems, however, are more suitable for storing light objects.

Also worth mentioning hanging shelves. They will not be able to fully replace the rack, but they will be able to supplement it. By placing several of these shelves under the ceiling, you can organize a storage place for items that are rarely used. Hanging shelves can be equipped with drawers for storing trifles, they can be angled - there are a lot of options. The main thing is not to overload this storage place, since all the load goes to the wall.

Along with wall shelves are used and ceiling. They can also be regular or angular, can have several tiers, equipped with drawers for storing items. This is an ideal way to use the free space under the ceiling.

Material of execution of a garage rack

Let's start again with a stereotype that assures us that the best shelving is a metal shelving. And to argue with this statement is difficult. Indeed, if you need to store something heavy, then metal is an ideal option. But if in the garage there is nothing heavier than a pump or a drill, then alternative solutions can be found.

So, for the manufacture of shelving the following materials are used:

- metal. The frame is assembled from a corner and a profile pipe, the shelves are made of sheet metal. As a rule, steel is used, which is coated with a layer of powder paint that prevents corrosion, since dampness, i.e. high humidity - in garages are not uncommon. A more serious option is galvanized steel. Metal racks are as strong as possible, so that it will be safe to store tires and heavy tools on the shelves. The advantages also include high durability and resistance to fire. The downside is susceptibility to corrosion, but manufacturers are struggling with this issue by applying protective coatings. If you make a rack with your own hands, then the issue of protection against rust will fall on you - fortunately, there are enough special tools for sale. Another disadvantage of the metal shelving is the price, but such an investment is more than paying off with durability and reliability,

- tree. Previously, when ready-made shelves were not sold, the craftsmen had to make them with their own hands, and often wood was used as a fairly affordable and easy to process material. Today, wood is still actively used in the manufacture of shelving. To create a frame, a beam of 50 * 50 mm is used, and for shelves - boards, plywood, OSB or particleboard. The main plus is the low cost, in addition, a wooden rack is easy to assemble with your own hands. The design is lightweight, because hanging installation is possible with any wall material. A heavy metal rack, by the way, is not recommended to be attached to the walls of aerated concrete. The disadvantages of the tree, alas, are many. This is not such a high strength as that of metal, fire hazard, exposure to moisture, temperature extremes and microorganisms. To extend the life of the structure, you will have to regularly process wood with special substances. Experienced car owners recommend first impregnating the wood with a means of increasing resistance to moisture, and then covering it with a coat of paint,

- plastic it is used extremely rarely and the reason is clear - inability to withstand more or less high loads. Today there are racks for hardware on sale, their frame is metal, and the boxes are plastic. Boxes are divided into compartments, so they can store dozens of types of various fasteners. A convenient option for the workshop, but in an ordinary garage there are unlikely to be so many different hardware to fill even a small rack.

Separately, it is worth noting the combined racks in which the frame is made of metal and the shelves are made of wood. If you are not going to store anything very heavy, then this is a great option. Some craftsmen who decided to make a rack with their own hands and are not averse to saving money, some of the shelves are made of metal, and some are made of wood. So that such a trick does not go sideways, you need to imagine in advance what will be stored and where.

Permissible load

Tires, motor, wrenches - all these are quite heavy things, and the shelves under them should not bend and break. Therefore, again, think over what you will store and study the characteristics of the rack when you purchase it. Among others, there will be a load that a shelf and a rack section can withstand.

The most “tender” racks can withstand up to 60 kg per shelf and 350 kg per section. For more or less serious loads, it is better to take models that withstand up to 120 kg per shelf and up to 500 kg per section. Stronger models withstand 170 kg per shelf and 750 kg n rack. There are also the most durable models that can withstand a load of 300-900 kg per shelf. There is a need for such structures, perhaps, in auto repair shops, when it is necessary to store several sets of wheels, among which there may be trucks.

Garage Rack Dimensions

Typically, racks are placed along one of the walls - such a solution allows the most efficient use of the garage space. Make several measurements in advance to know which limit in height, length and width to count on. Keep in mind that many manufacturers sell shelving in vertical sections from 70 cm to 1 m or more in length, so it will not be difficult to assemble a structure of the required size.

Here are some guidelines to consider when selecting shelving sizes:

- height. It is better to take as high a rack as the ceilings in the garage allow. Thus, it will be possible to place a maximum of things on the same area. Shelves for sale are 1.5 m, 1.8 m, 1.9 m, 2 m high, less often you can find other sizes,

- shelf depth. Here the balance is important. On the one hand, the shelf should be roomy. On the other hand, too wide shelves take up a lot of space, and if you store all sorts of little things on them, then access to objects in the background will be complicated. The depth varies from 30 to 80 cm, the step is 10 cm. The optimal depth is 50-60 cm, but, first of all, you need to take into account what exactly you are going to store. It’s clear that for dimensional objects it’s better to choose the shelves deeper,

- section length. The gold standard is 1 m. With a standard frame, a shelf of this width will be strong enough. To assemble a rack with a length of 4 m, for example, it is possible from 4 sections of 1 m. If for some reason it is necessary that the length of the section be more than 1 m, you will have to fork out for a reinforced structure with a channel or a thick beam. It will cost more, and if you do it yourself, the manufacturing process will be more complicated,

- distance between shelves can be almost anything. It is convenient when the position of the shelf can be adjusted to adapt the rack to store certain items. It is recommended that the first shelf be located at a height of 30-50 cm from the floor. This will ensure proper safety for you and allow easy cleaning.

If desired, sections of different heights can be combined; the width of the shelves in them may also vary. In general, only you know which rack will fit perfectly into your garage and meet all the requirements.

Secrets of organizing space

The experience of numerous garage owners suggests how to properly place everything on the shelves of the rack, so that everything fits and nothing falls. Here are some tips you might want to listen to:

- it’s best to put the rack under the long wall of the garage,

- The most commonly used items are stored on shelves, which are easier to get to. Everything that is necessary from time to time can be placed higher,

- it is better not to place containers under the ceiling that can be knocked over when you try to get it from the top shelf. In general, canisters with flammable liquids are best stored on the lower shelves away from electrical wiring,

- in the presence of a large number of tools, you can select a separate wooden shelf for it, in which to make the required number of holes. Screwdrivers are inserted into them, and as a result, the search process is noticeably simplified,

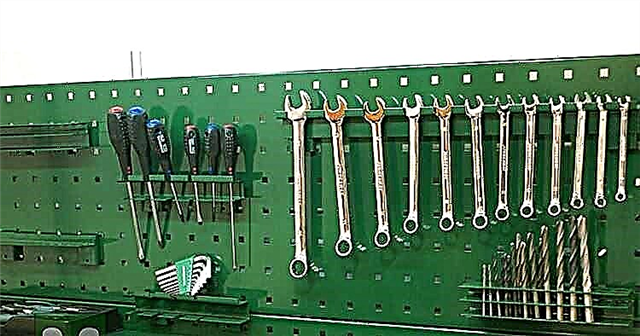

- Perforated panels are perfect for placing keys; hooks are attached to them, for which the keys hold perfectly. Such a panel can be made part of the rack or taken out of it,

- for a hand-held electric tool, drawers can be provided, or stored in shelves of a workbench, if any,

- To simplify the cleaning process, some prefer to use shelves made of metal mesh. The dust on them does not linger, it easily falls to the floor, from where it is much easier to remove it,

- tires are stored on the lower shelves, and the shelves themselves are removed, leaving only horizontal horizontal bars. Up to 5 tires for passenger cars are placed on a shelf 40 cm deep and 1 m long.

When buying a finished rack, find out how long the manufacturer has been working on the market, whether users are satisfied with its products, what materials it uses, how it protects against the negative effects of moisture, and what guarantees it gives. If there is time and opportunity, you can try to build a rack with your own hands, the following videos will come to your aid.

Functional purpose

A garage with racks and it without them are two big differences. Lovingly laid out in piles on the floor, the inventory will soon cause an irresistible desire to build shelves or open cabinets for storing the tool. And immediately everything will fall into place: each part will have a separate cell, it will be easy and comfortable to use the placed things.

You can make the necessary equipment in various ways:

- from wood and chipboard,

- metal shelves

- combined design.

Each option is justified - cost, ease of manufacture or durability. Which one to choose is up to the customer to decide.

Choose material

Durable metal shelves in a garage

DIY wooden shelves in the garage

For the design, stability of the frame, the practicality of the operation of the structure, the choice of the main material plays a huge role. The rack can be made from different raw materials, which has its own advantages and disadvantages. Consider the main types of materials, their features in the table.

| Material | Advantages and disadvantages |

| Metal | Many car owners prefer metal for its durability. Such material is durable, can withstand heavy loads. It can only be adversely affected by increased humidity. In normal climates, metal structures will last almost forever. Also, the advantage of such raw materials is the ease of care. Products will need to be periodically simply wiped with a cloth to maintain cleanliness. The main disadvantage of metal is its high price. However, many have unnecessary pieces of metal in the country, friends. Metal elements are usually joined by a welding machine. Using it without proper experience is not recommended. |

| Tree | Wood is a noble, healthy raw material. It makes excellent hanging shelves, racks, storage systems. Wood has a very beneficial effect on the human respiratory system, has an attractive appearance, and is easy to process. In the manufacture of storage systems, you can use oak, pine, birch. Fasten the frame only with metal bolts. Wood is relatively inexpensive. It can be purchased at any building hypermarket. The downside of this option is the difficulty in care. The tree gets dirty, it can get dark, rot. It should always be looked after. This is not always convenient. To reduce such negative consequences, it is recommended to use special impregnations. |

| Plastic | A good option for storing various small items, lightweight accessories. Plastic began to be used to make shelves relatively recently. It can withstand no more than 75 kg. This is worth considering! The advantage of plastic is light weight, mobility, ease of maintenance, low price. The downside is fragility. It is easy to damage, beat. Plastic is not suitable for storing metal tools. |

| Combination of two materials | For example, wood and metal. This is a great option for creating a multifunctional storage system. Thus, you can save, diversify the design of the garage, simplify the manufacturing process of the structure. You can combine almost any type of raw material. |

Metal shelving, collapsible with plastic containers

Drawings of popular designs

Schemes and a complete set of drawings for any garage rack can be easily found on the Internet. The most common options are:

- With a supporting frame made of steel profile (pipe, corner) and wall shelves. It can be modified into a wooden one - a skeleton of timber, boards, wood chipboards (OSB) are attached to it, rigidly or on brackets.

- Shelves hung on the wall. They can have a rigid frame with an insert made of chipboard or be integral - at the request and capabilities of the customer.

The calculations come down to linking the finished project to local conditions: the size of the wall allocated for the square shelving. The design can be not only straightforward, but also angular if the free space is in severe shortage. But it fits a bit on such a mini-rack.

Wall shelves

The solution is simple and justified. For its implementation, you will need to know the future dimensions of the structure, clearly determine which wall of the three in the garage to hang shelves to be convenient to use, and they do not interfere in everyday activities.

It’s good to draw a room layout as close to the scale as possible, and then “conjure” a little dumb over it, distributing the shelves taking into account the location of the car, its free check-in, and also the movement of people.

A properly placed rack should ideally fit into the interior: they will put everything you need on it, while they will not cling to clothes, touch your head.

Modular

Structures from prefabricated elements (modules) have several advantages compared to those that are rigidly fixed once and for all. From such a “lego” it is easy to assemble hinged shelves for your own needs (this is especially important for non-standard situations). Shelves are prefabricated, collapsible, multi-tier - such that they satisfy the needs and wishes of consumers.

Shelves in the form of a shield for the tool

In the car repair shop or where it is often necessary to repair, finding the right tool takes up a lot of precious time. It is much more convenient when everything is at hand, on a special shield. To make a similar design for keys in your garage does not seem to be a difficult, difficult task. But it’s easy to find a pipe wrench or pipe wrench, a puller, each placed in a specific place.

Hanging shelf variations

To make convenient functional hinged shelves, so as not to clutter up the free space, but to fully use it, is the dream of every owner. Which one to choose - narrow and long or short and wide - depends on the specific situation.

It is permissible to hang shelves at least to the very roof under the ceiling, the main thing is that they fulfill their task, and it is easy to get to them. In this case, put on the middle rows a tool, inventory that is used daily, and on the upper rows - what is needed once a year or even less.

Determine the design

Scheme of the simplest rack in the garage

Making racks in a garage with your own hands is quite simple. The most important thing is to clearly define your own desires, needs, pre-plan the design, type of construction. Such tasks will be within the power of anyone, especially if there is a great desire to do something with their own hands.

Drawing of a pipe rack with wooden shelves

The design of the racks has three elements: vertical racks, shelves, crossbars. In some cases, lateral tightening is used. They are not required. Only needed to increase the rigidity of the frame. To determine the exact design of the future rack, follow these recommendations.

- Depth, height of shelves - arbitrary. These parameters are selected only based on the purpose of the niche. Each shelf can be designed to store a certain type of thing. All this is best decided in advance,

- The distance between the uprights must be selected based on the stiffness of the material. For very heavy accessories, the distance should be about 1.5 meters. For a long shelf, intermediate vertical racks must be prepared. They will make the system more stable,

- The lower shelves should be at some distance from the floor. Approximately 50-70 cm. Heavy objects should be stored on them. The optimal height of the remaining shelves will be 37 cm. This is the most rational height, often used in the manufacture of any furniture design.

Drawing of a metal rack for a garage

Deciding on design features is always easy. The owners of the garage just take into account the dimensions, especially the things that will be stored in the structure.

Option for a small garage with a workbench

It's a little harder to choose a product design. The garage is designed for practical purposes. However, this does not mean that its interior should be boring, ugly. In the garage, you can easily make an attractive interior for little money. In particular, you can decorate the design of the rack with ordinary paint. Today there are paints designed for any materials. Color for painting should match the overall color scheme of the room. Colored plastic boxes for storing accessories and tools will become a kind of decoration. They are inexpensive, allow you to restore the perfect order.

Transparent and multi-colored plastic storage boxes for shelves in the garage

DIY Benefits

Many people ask a logical question: is it better to make shelves in the garage on your own or to buy a ready-made option on the market? Consider the main advantages of self-creation of a garage storage system.

Folding racks have an aesthetic appearance and are convenient for installation and dismantling

Ability to develop a unique design. For many car owners, a garage is a real pride. I don’t want to put ugly furniture in it. Standard shelves are also not very attractive. In this case, you can take up the work yourself, coming up with a unique design. Ideas for implementation can be found on the Internet. But it is better to unleash your own imagination.

The idea of arranging a garage inside yourself

To make hinged shelves, shelving is not as difficult as it seems. Such a task will be within the power of any man who has at least minimal experience with tools.

The manufacturing process does not take much time. Lack of free time is the main reason car owners buy garage furniture in the store. However, for the manufacture of the storage system does not require huge time costs. It is enough to allocate a few hours, call for help from a friend.

Homemade shelves and racks for the needs of the owner of the garage

Shelves can be made on a personal plan. Only the car owner himself knows what size, depth, height he needs shelves. Find the perfect option in the store is almost impossible. In hypermarkets, everything is standard. It is better to make a little effort, spend time, but create the most practical thing.

Low financial costs. Warehouse furniture is quite expensive. Even the simplest models will cost a large amount. Self-made is the best solution to save money. Many necessary spare parts can be found at your own farm.

Cabinet built into the rack system in the garage

Layout, diagrams, drawings, ideas

In the garage, you need not only a rack, but you also need a workbench and stand for hand tools - all kinds of keys and other small things, which are many and it’s difficult to come up with a specific convenient storage location.

A workbench can be made in the center of the rack. This is convenient - everything you need will be at hand, you do not have to constantly go to the shelves.

Garage racks with a workbench are convenient

A workbench can be part of the system, or you can make two separate modules, between which set the desired table. If this arrangement is not pleasant, it will be possible to change the configuration - at least put an angle.

As for the tool stand. There is a factory option - a perforated sheet of metal with holders hung on it. The idea is very good except for the price.

As usual, there are several homemade products (what a garage without them) on the same topic. Ideas are simple to implement, maybe not so elegant, but convenient:

- On planks, a sheet of chipboard, plywood, stuff nails under each tool. In order not to get confused where to hang something - circle the tool in place and paint over with some color.

Everything is in order and in place

For heavier equipment - large keys, etc. You can use a grid on which to hook the wires from the wire. Nail the wall.

Option for heavier and bulky tools

Make a bar with holes cut into it into which the tools fall.

It’s not difficult to make this tool stand with your own hands.

And if desired, all this can be put on wheels - to make the stand for the tool mobile. This is the case if in the warm season you prefer to work with the car on the street.

You can easily roll back to where you want

Well, and for inspiration ... so that all the tools are in place))

Necessary tools

Essential tools for making shelves

To the process of manufacturing shelves took a minimum of time, you should prepare the tools in advance. It will take not so much: a set of wrenches, pliers, hacksaws for wood, metal, hammer, screwdriver, puncher, jigsaw, grinder. All of these items have almost any good owner. The set of basic materials will depend solely on the choice of each individual. It can be plywood, metal pipes, bars, chipboard, plastic, much more.

Popular garage shelving options

Manufacturing process: step by step instructions

- Preparation of the place of work. Making a shelf is a dusty job. It takes a lot of space. To do this, it is better to remove the car from the garage. Foil should cover instruments, expensive items. Next, you need to prepare the tools, put them side by side. It is advisable to enlist the help of a friend. Together, the work will be completed as quickly as possible.

- Preparation of the plan. For ease of operation, the plan of the rack is better to draw in advance on a simple piece of paper. There it is necessary to note the measurements of each shelf. When preparing a plan, you need to consider specific things that will be stored on shelves. It is not necessary to make a standard design. In one system, you can combine several different elements.

Holders and Mesh Shelves

Installation of mesh shelves on the side of the garage - a quick option for light objects

Shelf manufacturing begins with the foundation

Marking on racks. Vertical elements need to be marked. This will help in the further installation of the crossbars.

We make grooves for shelves with a milling cutter

Drilling holes. Neat holes are made on the markings with a drill. This is typical when using bolt fasteners. When choosing a welded frame, all elements are joined by seams. In the absence of proper experience, the seams can come out ugly. It is also important to observe safety precautions when working with welding. This should be read more in the instructions for the welding machine.

We install a shelf in the grooves and additionally fasten with screws

Install the rack on the base

Shelf fastening technology

Shelves and racks, whether they are home-made or factory-made, must be securely fixed. In floor constructions, the supporting elements are racks that rest on the base and distribute the load, therefore, when calculating them, manufacturing, savings are unacceptable.

For hanging shelves in the garage, 2 main points are taken into account: the material of the walls and the design of the suspension. Both that, and another should support the weight of additional designs, to be reliable. For weak, not thick enough walls, you will have to replace the option with shelves on the rack.

50 interesting options for decorating shelves in the garage:

How to make a do-it-yourself cardboard display rack

How to make a do-it-yourself cardboard display rack

Furniture made of cardboard is an original, affordable way to turn unnecessary material into an unusual, charming thing. In appearance, it almost does not differ from furniture purchased in a store, ...

We make a convenient rack with our own hands

We make a convenient rack with our own hands

Preparing tools for a rack Most likely, you just do not have enough shelves to store many useful things. Jars for canning and ready-made preparations for the winter, electric ...

DIY Corner Shelf

DIY Corner Shelf

The problem of space is relevant for small and large apartments. It is very difficult to fit everything you need into a limited square meter. It is almost impossible to imagine a house, office or apartment ...

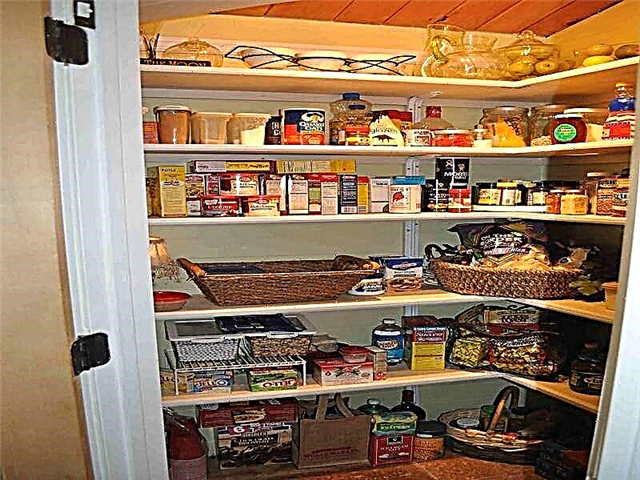

How to make shelves in the pantry with your own hands.

How to make shelves in the pantry with your own hands.

Current developers, unlike colleagues of the previous generation, do not seek to equip living space with storage rooms. This increases the living space, but does not allow to optimize the space and ...

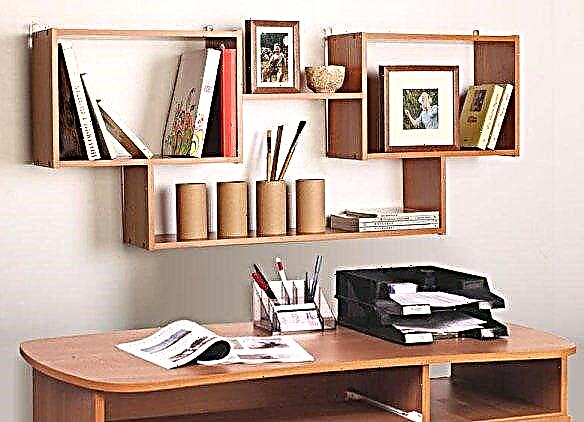

We use shelves above the desk

We use shelves above the desk

A well-designed work area is the main task of parents. If earlier it was customary to do homework in the kitchen, now it is in the order of things to have a corner-office in the house. To all school supplies and others ...

Shelf "house" - a convenient and original idea for the nursery

Shelf "house" - a convenient and original idea for the nursery

We present an interesting solution for the nursery - shelves in the form of a house. This design will appeal to any child aged 3 to 10 years. Its purpose is the storage of toys and other accessories for ...