Modern types of floor coverings require a perfectly even rough foundation, on which they will be laid. In most cases, the surface before the finish must be leveled with a small layer. To do this, use special mixes for the floor of the Volgograd company Volma. They are quality and affordable.

Assortment of Volma products

The Volgograd trademark that sells floor mixes provides consumers with a wide selection of different finishing materials in containers of 10, 15 and 20 kg. All products receive positive feedback from consumers and are in high demand. All this is achieved by the company due to the high quality of materials and low cost. The most popular and widespread are dry mixes for leveling the concrete floor Volma-Level Express.

Basic Volma bulk floor Leveling device Rough

Volma Leveling Coarse Rough, is a base coat that can be used as a screed. Lime gives plasticity to the solution, reinforced fibers guarantee a durable coating. Before starting work, the manufacturer recommends fixing the damper tape along the perimeter of the working surface adjacent to the walls or supporting columns. This will reduce the likelihood of cracks at the joints.

Volma Leveling agent coarse 25 kg

After drying of the Rivifier, it is necessary to use the finishing self-leveling bulk floor of Volma. During pouring, it is required to close any sources of drafts and prevent sunlight from entering the solution and the flooded surface. You should also remove oil or grease stains, bituminous mastics - all this affects a decrease in adhesion. If there are any cracks, they must be deepened, dust removed and primed. When the soil has dried out, flaws are required to fill the Volma Roughing Rough. Only after 72 hours can you start filling the floor. Full drying takes 3-4 weeks, but laying ceramic tiles and filling the floor is allowed after 1-2 weeks.

18-20 kg / sq.m with a layer of 1 cm

150 g of water per 1 kg or 3.75 per 25 kg

Technical bypass at a temperature of 20 ° C

- applied inside and out,

- economical consumption.

- requires topcoat.

Non-shrink bulk floor Volma Level Arena

Bulk cement floor with dispersed additives that stop from subsidence of the layers. Volma Nivelir Arena is ideal for pouring surfaces with differences of 0.5-10 cm, experiencing moderate loads. It is recommended to perform work in a warm room at a temperature of + 5 ° C to + 30 ° C. In one session, it will work out 20-25 sq.m.

Volma Level Arena

To prepare the mixture, 25 kg of powder is poured into a container with 5.75 liters of water, stirring constantly until a smooth consistency is obtained. After, let it brew for 5 minutes and mix again. While the suitability of the Bauproffe Leveling mortar is only 30 minutes, the Arena ready mix can be used for 60 minutes.

16 kg / sq.m with a layer of 1 cm

150 g of water per 1 kg or 3.75 per 25 kg

Technical bypass at a temperature of 20 ° C

The cost of 324 rubles.

- suitable for underfloor heating with electric heating,

- moisture resistant coating

- use with fresh cement base for up to 30 days is prohibited.

Quick-hardening bulk floor Volma Level Express

Volma Level Express express floor is a self-leveling and quick-hardening coating, which is used only indoors with heating. Suitable for use on concrete and cement-sand substrates in places that are not prone to high humidity. The mixture can be layered and used for differences from 0.5 to 10 cm.

Volma Level Express

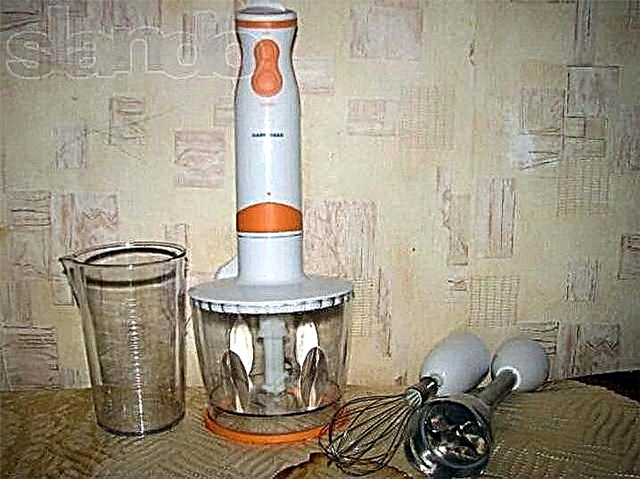

To dilute a solution of 20 kg of bag, you need 5.8-6.8 liters of clean water. Mixing to a homogeneous mass can be done with a drill with a mixer nozzle. Make sure that there are no lumps and let the mixture swell for 2-3 minutes, then mix again and start pouring. The leveling floor Level Express allows you to make technical penetration after 4 hours, but it is better to decorate the floor after 7 days. The viability of the solution is an entire hour, in contrast to 30 minutes of the analogue of the bulk floor of the Boden Level of the Bergauf company.

12.5 kg / sq.m with a layer of 1 cm

0.29-0.34 L of water per 1 kg or 5.8-6.8 L of 20 kg

Technical bypass at a temperature of 20 ° C

- suitable for underfloor heating system,

- no cracks and drops,

- durable and inexpensive.

- quick drying on the surface,

- cannot be used in the bathroom, saunas, etc.

Thin-layer quick-hardening bulk floor of Volma Level Top

This self-leveling floor allows for finishing leveling for subsequent finishing with floor coverings. It is characterized by the fact that they are used only with minor differences from 3 to 20 mm. Despite the fact that the analogue from Roussean has an advantage in the permissible pouring height, the plasticity time of the Level Top is 10 minutes longer. To dilute 25 kg of powder, you need 5.25-6 liters of water. Apply exclusively by hand.

Volma Level Top

4.8 kg / sq.m with a layer of 3 mm

0.21 -0.24 L of water per 1 kg or 5.25-6 L of 20 kg

- For interior and exterior use,

- warm floor.

- not intended for freshly laid cement base,

- cost.

Self-leveling bulk floor Volma Level Comfort

The bulk floor of Volma Level Comfort is self-leveling. The characteristics of increased strength allow it to be used in ordinary residential premises, as well as in places of constant crowding - public institutions, train stations, shopping centers. Packing of the bulk floor from Volma Level Comfort is 20 kg, it is enough to fill 1.6 square meters with a layer height of 10 mm, which cannot be said about the bulk field Etalon Level, where at the same thickness, the flow rate increases to 28 kg.

Volma Level Comfort

The mixture is applied manually or using specialized equipment. The minimum room temperature during installation is 5 ° C. The room should be dry and the humidity of the base should not exceed 6%. If you work with a large area of 50 squares, you will need to install an expansion joint, strictly on those that are already in the base. After cleaning, do not forget to work through the floors with a primer, and only after complete drying can the foundation be poured.

The manufacturer recommends a test for the spreadability of bulk floors Volma Level. It is necessary to pour a liter of solution on a smooth surface that does not absorb it - glass, plastic film. A spot that spreads 50-55 cm in diameter indicates suitability and good consistency.

Description of VOLMA-Level Express

TU 5745-009-78667917-2008

VOLMA – Level Express is a dry mixture based on a complex binder, fractionated quartz sand and modifying additives, which provide high solution mobility, strength and optimal working time.

For manual or mechanized work on leveling concrete and cement-sand substrates of the floor indoors for subsequent decorative coatings (linoleum, laminate, tile, parquet, etc.) with a thickness of 5 to 100 mm. It is recommended for use in residential and public buildings with a dry and normal level of humidity.

The base must comply with the requirements of SP 71.13330.2017, be durable, without peeling, clean, free of dust, dirt and grease stains. The "age" of the cement-sand base should be at least 28 days, and concrete - at least 3 months.

Before pouring, it is necessary to fix the damper tape around the perimeter of the walls and columns in places adjacent to the floor. All metal elements in contact with the mixture should be protected from corrosion.

The required thickness of the future layer is set using portable beacons, benchmarks and leveling line. Identify areas for filling the floor. If the land for alignment is more than 50 sq.m. and with a diagonal of more than 10 m., in the floors a deformation seam should be arranged and always above the existing seams in the bearing base. The base of the floor and the place of the walls that will be in contact with the bulk floor must be treated with Volma's “Universal” primer 2-3 times. You can start pouring the bulk floor after the primer has completely dried.

For manual application: pour the dry mixture into clean water (water temperature from +5 to +20 ºС), based on the proportion of 0.29 - 0.34 liters of water per 1 kg, and mix using a professional mixer or drill with a nozzle to a state homogeneous mass for 3-5 minutes. Allow the solution to stand for 3 minutes and then re-mix. Do not overdose water!

To check the consistency, pour 1.0 L of the solution onto a flat, non-absorbent base (e.g. glass, film, foil). The diameter of the spot should be 50-55 cm.

For machine application: pour the dry mixture into the hopper of the machine (unit) and, adjusting the water flow rate, select the required consistency of the mixture.

Consistency check: pour 1.0 liter of solution onto a flat, non-absorbent base (e.g. glass, film, foil). The diameter of the spot should be 50-55 cm.

1. Pour the prepared solution of the Volma-Level Express mixture evenly to the required thickness, avoiding breaks of more than 10 minutes.

2. Then, starting from the areas adjacent to the walls and columns, remove air bubbles from the solution using a needle roller or a construction mop of 1 m or 2 m. Movement with a construction mop is carried out along and across the flooded surface, creating a "wave".

3. The time to fill the Level Express bulk floor depends on the conditions (temperature, humidity, base absorption, layer thickness) and is no more than 40 minutes.

4. During hardening of floor mixtures on a complex binder during the first two days, drafts and direct sunlight should be avoided. Then provide natural ventilation and ventilation of rooms without using heat guns. In the winter, do not allow the temperature of the room to fall below + 5 ° C.

5. The drying time of the bulk floor depends on the thickness of the layer, temperature and humidity in the room.

6. Laying a decorative coating on a leveled floor can be done at least 7 days after pouring. The residual moisture of the poured floor during laying of the subsequent coating should not exceed 1%.

"VOLMA-Level Express" is ideally suited for work in the "warm floor" system.

The minimum layer when pouring the bulk floor in the "warm floor" system is 45 mm. If the “warm floor” system is mounted in the base base, the thickness of the fill is from 5 to 100 mm. The first inclusion of a heated floor should be made no earlier than 7 days after pouring the floor, setting the temperature 25 ° -27 ° C for 2-4 days. Full operation of "warm floors" - not earlier than after 28 days.

Bags with the VOLMA-Level Express dry mix should be stored on wooden pallets in dry rooms. Pour mixture from damaged bags into whole bags and use first.

The warranty period of storage in undamaged original packaging is 12 months.

Perform work in accordance with construction requirements, standards and safety and health standards.

Dry mix for finishing leveling floors "Level Express"

Volma bulk floor is used to form the topcoat before laying floor finishing materials. The mixture is based on gypsum with quartz sand as a filler. The composition also includes polymer, binders and modifying components that give the solution plasticity. The mixture is used only indoors. The layer thickness can vary from 7 to 100 mm.

Technical characteristics of Volma-Level Express:

- Setting time from 4 to 6 hours. Varies depending on the ambient temperature and the humidity level in the room.

- The adhesion to the rough surface is 2 MPa.

- Fully floors mature in a week and a half maximum (depending on the thickness of the layer).

- The finished base can withstand loads up to 16 MPa.

The price of one package is small - about 100-200 rubles per 20 kg of Volma-Level Express dry mix. The consumption is also small: with a layer thickness of 10 mm, such a mass is enough for 4-4.5 m 2 of surface. Compared with similar compositions of other brands, Volgograd products are much more profitable. Moreover, its characteristics are similar, and in some cases even higher.

Work surface preparation

For the most part, leveling mixtures, including the Volma bulk floor, are intended for leveling cement-sand or concrete screeds.

Preliminary preparation of such surfaces includes:

- Cleaning the base of construction debris, dust and dirt.

- Existing cracks expand, deformed sections and the remains of the old coating are removed.

- Secondary cleaning of the surface from dust.

- A deep impregnation primer is applied. This is done only once. It is advisable to purchase a primer of the same manufacturer. The composition is applied using a paint roller.

- After the primer layer has dried, a damper tape is placed around the perimeter of the room.

Solution preparation

The dry Volma-Level Express mixture is delivered in packages of 20 kg. In order to prepare a solution, about 6 liters of pure water is required for this volume of material. It is advisable to use a cold liquid. The vitality of the prepared Volma-Level Express solution lasts about 60 minutes. The characteristics of the mixture after this time do not deteriorate, but working with it becomes harder. For an hour, it is desirable to distribute the finished solution on the surface. If you plan to process a large area, then initially it needs to be divided into several technological areas.

The volume of water indicated on the packaging of the mixture is poured into a previously prepared container. Then gradually and in small portions dry material is poured from the bag. Mix the resulting mixture after 3-5 minutes. During this time, the powder should have time to be saturated with water. Mix the components using a construction mixer or drill with a special nozzle. After the first "shuffle" the mixture is left to infuse for 5-10 minutes, after which it is mixed again. At the end of the preparation of the solution, you can begin to level the floors.

Work with a solution on a surface

The finished mixture is poured first into deeper potholes and cracks with a gradual transition to higher elevations. All work is preferably done by two people. One will prepare the solution, the second - fill. To level the composition, a needle roller on a telescopic handle and a spatula are usually used. The length of the spikes should not be less than 30 mm.

The solution poured onto the surface is leveled with a spatula so that the resulting strips are facing each other. Upon reaching the edge of the restricted area or on one side of the room, the composition is several times passed with a needle roller. This is done to eliminate air bubbles from the mixture, the formation of a flat surface due to the movement of the solution and vibrations.

Before you start pouring the Volma-Level Express mortar, you must close the doors, windows and windows, so as not to create drafts. If they are not eliminated, they can cause cracks on the surface and reduce the strength of the finished floors.

After four hours from the moment of filling the floor, you can move on it, after two days you can start laying ceramic tiles. Laminate or linoleum is laid only after the surface has completely dried.

Advantages of Volma bulk floors

Products manufactured by the Volgograd company, in comparison with other trademarks, have the following advantages:

- With proper dilution of the dry mixture, the finished solution has a liquid consistency. The density of the composition can be controlled by adding pure water. Work with the solution is greatly facilitated due to the fact that it is independently distributed on the surface.

- Low price of dry mix in comparison with import brands. Despite this, the composition has established itself at a fairly high level and has earned popularity among consumers.

- The composition includes polymer components that increase the life of the coating and increase its strength. After 7-14 days - the full pour time of the mixture - the coating is able to withstand loads of 12 MPa.

- The processing of Volma mixtures is carried out both manually and automatically. Other bulk floors are suitable for only one treatment method.

Customer reviews of Volma products

Dry mixes of a trademark are one of the most popular and widespread among similar goods. Many customer reviews left on the Volma-Level Express filling field emphasize only the positive qualities of the solution — low cost, ease of use, average consumption of the composition per square meter of surface, the ability to level on its own, and the high strength of the finished coating. However, many consumers also note that one of the advantages of the composition - fast solidification time - can be attributed to the minuses. Especially for those who can not carry out all the work in a short time. Despite this, the finished surface is perfectly flat and suitable for subsequent finishing and laying of floor coverings.

What it is?

The mixture is made of gypsum base using quartz sand, a polymer modifying additive and binders. The combination of the main components gives the mortar a high plasticity, ensuring perfect leveling of the subfloor. The thickness of the working layer is from 7 to 100 mm, which allows you to align problem surfaces with large elevations and pronounced defects. The material has enhanced adhesion properties to the lower plane of 2 MPa, which makes it capable of withstanding a load of up to 16 MPa.

The solution has a short setting time (4-6 hours), depending on the temperature and humidity of the surrounding space.

Complete drying of the composition occurs after 7-10 days and depends on the influence of external factors and the thickness of the applied layer. The packaging of the mixture weighs 20 kg, which is enough to fill a centimeter layer of the solution on an area of 4.5 square meters. m. The cost of the material is 230-250 rubles and makes it the most budget option among similar products of European brands.

The shelf life of the dry mix is 12 months.

Application area

Level Express is a high-quality leveling material and can only be used for internal work. The composition is used to fill the main floor made of concrete or cement-sand mixture, and can serve as a rigid base for any type of floor decorative coating: carpet, linoleum, parquet, laminate or tile. Due to the optimal cost and excellent quality, the material is used for flooring both in new buildings and in public institutions.

Advantages and disadvantages

Level Leveling agent “Level Express” is deservedly in high demand and popular in the domestic market of building and finishing materials.

The products of the Volma enterprise are quite recognizable and have the following indisputable advantages:

- Particular strength of the material is achieved due to the balanced composition and excellent quality of all components. The surface is impact resistant and not prone to cracking. The mixture can be used to level floors in workshops and production rooms where heavy equipment is expected to be placed,

- High levels of alignment due to the high plasticity and mobility of the solution. The pouring process does not require special knowledge, skills and additional labor costs. After drying, the rough floor does not need additional grinding. Roughnesses and elevations are leveled, and the floors get an absolutely flat surface. When zoned casting, there are no joints on the surface, and the absence of shrinkage of the material allows you to mount the decorative coating immediately after drying - after 10-14 days,

- Absolute environmental safety of the material is guaranteed by the use of natural components that are completely harmless to health and do not cause allergic reactions,

- The high thermal conductivity of gypsum makes it possible to install floors with electric and water heating without the risk of heat loss,

- Quick hardening allows you to move on the floor surface within 6 hours after pouring. The prepared solution is suitable for use within an hour, and the final hardening occurs after 72 hours.

The disadvantages include a short time of suitability of the solution for work. For people who do not have experience in construction, it can be difficult to cope with the pouring within an hour. In the case of slow work, there is a risk of premature setting of the composition with the impossibility of its further use.

This indicator must be taken into account during installation.

Features of the preparation of the mixture

The breeding algorithm is clearly stated on the package and is as follows:

- In a clean, dry container, pour cool water, the temperature of which does not exceed 20 degrees. The use of warm or hot liquid will lead to a quick solidification of the solution and the inability to continue casting. For 1 kg of dry product, 0.3 liters of water is required. In order to prepare a solution from a standard twenty-kilogram pack, you will need 6 liters.

An overdose of water is unacceptable - the liquid solution loses its technical features and characteristics, which subsequently leads to delamination of the surface,

- Next, proceed with backfilling of dry material. The mixture should be added in small portions while stirring. Mixing should be performed with a construction mixer or drill using a special nozzle-blade,

- It is necessary to leave the resulting solution for 5-10 minutes, and then mix thoroughly again. The consistency of the resulting composition should resemble sour cream,

- The consistency of the resulting solution can be checked by pouring a liter of the mixture on a flat, non-absorbing surface.

With an ideal ratio of components, the resulting spot will take the form of a circle with a diameter of just over 50 cm.

Pouring technique

Installation of the bulk floor should start from the far corner of the room. The mixture is evenly distributed on the floor with a spatula, and the resulting bubbles are removed with a needle roller with a telescopic handle. The spikes should be no more than 30 mm in length and exceed the fill layer. As a result of leveling, an absolutely smooth surface with a characteristic glossy sheen is obtained.

To comply with the required thickness of the formed layer, special beacons must be used, setting them at a distance of 1.5 m from each other.

Using the step-by-step technique, strips are applied in parallel until the entire rough foundation of the floor is filled. When pouring the solution, it is necessary to monitor the uniformity of filling and avoid technological interruptions. When the entire surface of the floor is flooded, it is necessary to remove the beacons and levels and quickly walk along the floor with a roller. This will allow you to form a flat surface and smooth out the "folds" that may form when working with a spatula.

Leveling should start from walls or columns and make it progressive movements in all directions.

The diluted solution should be used within an hour. When pouring large areas, the zoning method should be applied, and each technological section should be installed separately. The area of one zone should not exceed 15 square meters. m. You can walk on the freshly poured floor already 4 hours after the end of the work, lay the tiles in 2 days, and lay linoleum in 10-14 days.

Installation of decorative flooring can only be carried out if the indicators of residual moisture content of the poured floor do not exceed 1%.

Useful Tips

Before starting pouring, it is required to close the doors and windows tightly. This will help prevent drafts that cause cracking of the drying screed. Direct sunlight should also be avoided: their influence adversely affects the quality of the upper layer. Relative humidity should not exceed 75%.

To ensure natural ventilation, short-term regular ventilation is recommended.

In cases of violation of the pouring technology, excess water entering the solution or obvious defects of the main surface, the self-leveling floor may crack within a few hours after installation. If the top layer has peeled off or cracked, it is necessary to expand, dust out and prime the cracks. Then you need to fill them with the newly prepared mixture "Level-Express" or repair composition. Subsequently, the repaired surface is reinforced with plaster mesh or fiberglass.

In case of delamination of the bulk floor, it is necessary to remove the departed top layer, and after dedusting and priming, pour a new solution. If the delamination of the material occurred over a sufficiently large area, then spot repair will not help. In this case, it will be necessary to completely dismantle the damaged surface, followed by a new fill.

Good examples and options

The self-leveling composition “Volma-Level” will help to achieve an absolutely even and durable foundation on which any decorative coating will last a very long time without losing its original shape and appearance:

- With the correct preparation of the solution and observing the technological features of the installation, the gypsum-based self-leveling floor will have a perfectly smooth surface with a glossy sheen

- Excellent ductility of the composition contributes to uniform spreading and allows you to align the defects of the subfloor,

- Despite the method of separate pouring of technological areas, which is used in large areas, there are no joints and seams on the frozen surface,

- The mixture is suitable for both manual and machine pouring, which is very convenient when it is installed in spacious rooms and industrial premises,

- The use of needle rollers allows you to achieve the formation of a smooth surface, which will serve as an excellent basis for linoleum, carpet and tile.

You can find out how to do the installation of the bulk floor with your own hands from the video below.