In the construction industry, many different compositions are used. When performing installation work and repairs often can not do without sealant. The modern market offers a huge variety of products that differ in composition, purpose and operational characteristics. Consider this market segment and dwell on black silicone sealants.

Features

The main purpose of sealants of various types is to fill holes and cracks due to the design of a dense and airtight layer. To make the right choice of composition, you must initially determine in which particular area the product will be used.

Black sealants are special formulations with the addition of a dye. This product has certain uses, some of which differ from neutral silicone sealants.

Range

A layer of hardened silicone sealant cannot be treated with paintwork because of its elasticity, but it will not be difficult to find a suitable option. Manufacturers have developed a wide color range of products, given the huge variety of finishing materials and styles. There are transparent, colored and black silicone-based sealants on sale.

Varieties in composition

All products from this category can be divided into two types: one-component and two-component compositions. Products from the first category are most often used in everyday life. They are sold ready to use and it will be easy to apply sealant even to a novice.

One-component compositions are divided into the following types, depending on the components in the composition.

- Neutral The name speaks of versatility. This type of sealant is compatible with various surfaces.

- Alkaline Amines are a part. This is a special product.

- Acidic. The most affordable option. Acetic acid is used in the manufacturing industry.

For the manufacture of two-component compositions using a hardener and a base. Each of the components is stored in a separate container. Elements react when mixed. Such a variety is used, as a rule, in the industrial direction.

Consider what else are black compositions.

- Bituminous (roofing) sealant - the product is intended for laying a drainage structure or tile.

- Plumbing (sanitary) - carrying out repair plumbing. It is used in showers and on the basis of bathrooms.

- Aquarium - the name of the product speaks for itself. Sealant for the repair of aquariums and similar structures.

- Low-modular - for the design of interpanel joints.

Destination

A variety of silicone sealants, presented by large specialized stores, will confuse every inexperienced buyer. The compositions are divided not only by composition, but also by the nature of the application.

Depending on the destination, there are three main areas: special, construction and automotive. Some of them are narrowly targeted compositions, others are more popular.

One of the special products is the automobile black compound.

Black silicone-based sealant is actively used for vehicle repair and maintenance. It is necessary when replacing gaskets or conducting technical work.

It is worth noting that this is not the only area of use of black sealants. They also found their applied in everyday life. Black silicone sealant is often used as a grout on the basis of bathrooms and other similar rooms. Dark colors are ideal for both classic and contemporary styles.

For work with natural materials, for example, granite or stone, the black composition is also in demand. It has all the necessary technical characteristics, depending on the purpose.

Performance characteristics

The use of black sealant is determined by its special characteristics:

- dense texture that does not spread and retains shape when applied,

- the maximum temperature index held by the sealant is 300 degrees Celsius with a plus sign (for short-term exposure),

- the material is not subject to aging

- Excellent resistance to water, antifreeze and engine oil.

How to choose the right composition?

Depending on the type of base and field of application, one or another composition is chosen. Russian consumers at a high level noted the product of the brand Kim Tec. The silicone compound is actively used as an insulator for door and window openings, as well as aquariums. The main purpose of the sealant is to prevent particles of contamination and moisture from penetrating inside. The main advantage of the product is its use indoors and outdoors.

The composition can be used when working with metal, ceramic, wood and glass bases. Silicone rubber, which is the main component in the composition, has high resistance even when exposed to weather conditions.

Black sealant, if used properly, will retain all operational characteristics for at least 10 years. The product is completely safe for health. Full hardening occurs after 24 hours.

How to determine the composition of high quality?

Experts assure that the main criterion for the quality of the goods is the share of fillers in the basis of the sealant. That is, the more silicone in the composition, the more practical and durable adhesive. Pay attention to 100% sealant. This is a top quality product. The sealant has excellent performance characteristics, including a long service life, elasticity, practicality, low shrinkage and other positive qualities.

The sealant, which contains a small amount of additives, is also recommended for use. The black sealant “101” belongs to this segment, as well as a compound called Ceresit CS 25. Due to its special characteristics, the product is used in rooms with increased moisture and moisture (bathrooms, pools, warehouses, basements).

The use of compounds of this type prevents the development of mold and fungus.

Quality Tips

To distinguish high quality material, Take the advice of professionals.

- When weighing a tube with a sealant with a volume of 310 millimeters, the approximate weight should be about 340 grams. If the value is higher than the declared norm, there are many fillers in the composition.

- Manufacturers use the letter “A” to indicate acidic products. In the absence of marking, this composition can be distinguished by the pungent smell of vinegar.

- If, when using a sealant on a polyethylene surface, the product begins to lose its shape and inflates, this indicates the presence of a solvent. Unfortunately, this cannot be verified by weighing.

In order not to spend money on fake goods, make purchases only in trusted stores. Demand the availability of appropriate certificates that clearly demonstrate the quality of the products.

Characteristic properties

Silicon is used in the manufacturing sector. It is a natural material that exists in the form of quartz or sand. It is used to make polymer - the basis of silicone.

This component, which is the basis of black silicone sealants, has special properties.

- Elasticity. Products are used for reliable bonding of wood, glass, concrete and other materials.

- Strength. The sealant, made in accordance with high quality standards, is able to withstand high temperature loads.

- Reliability. If the composition is selected correctly, the material reliably glues surfaces, regardless of their texture.

- Sealing. Long-lasting and practical joint sealing.

- Durability. The material is resistant to the vagaries of weather, dampness, direct sunlight and other factors.

Using

Working with black sealant is easy even if you are going to use the composition for the first time.

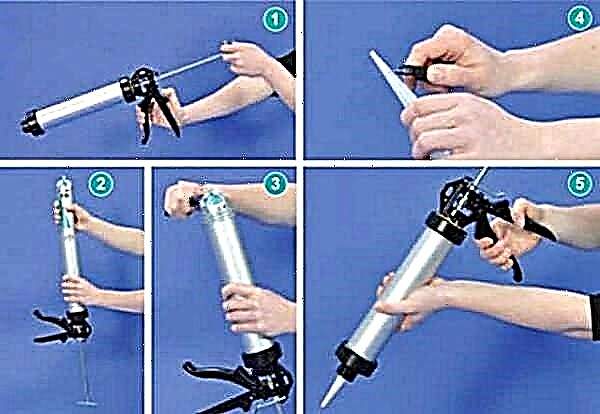

- To perform the job as efficiently as possible, accurately and quickly, it is recommended to use a special gun.

- After unpacking the container with the composition, a special dispenser is put on the tip of the nozzle.

- The size of the cut depends on the desired supply volume of the consumable.

- Before applying sealant, the work surface must be cleaned and dried.

Remove excess particles of the solution before it hardens. Otherwise, you will have to clean mechanically.

Reviews

To summarize the article with product reviews. Considering the fact that silicone sealants have been in great demand since it was on sale, there are many messages and responses on the network. Opinions about black sealants are shared by professionals from the field of construction and repair, as well as ordinary buyers.

Most reviews indicate that silicone is a bargain. A lot of positive reviews indicate that the black compositions are actively used both for minor repairs in the home and in various industrial fields. Black color fits perfectly into various interiors, from a design point of view.

Negative feedback is also available. Some are sure that colorless and white compositions due to the neutrality of the shade are more suitable for domestic use. This is due to the fact that black is easily soiled.

See how to wash a car from silicone sealant in the next video.

What is sealant used for?

TOP-8 The best paints for the ceiling: the priority of reliability and durability. Overview of the most popular manufacturers

Insulating compounds are used for processing joints and gaps between plumbing and the wall

A sealant is a viscous mass based on polymers of a heterogeneous structure, used in construction for durable bonding or compaction of materials. It happens single and multicomponent.

In the composition of the product:

- polymers (base)

- filler

- hardener

- dye

To reduce the cost or give additional properties, additives are added to the product, which make up no more than 10% of the volume.

Among the most common additives are:

- expanders (extenders)

- fillers (flour from quartz, chalk)

- fungicides

- mineral oils

Previously, cement based grouts were used instead of polymer sealants in bathrooms.

Silicone Plumbing Sealant

Sealants for plumbing work are used for:

- protect joints between the sides of the bathroom or shower and the tiles (tiled)

- seams between the back of the sink and the wall

- closing gaps between the bottom of the toilet and the floor

Sealing is necessary to prevent leakage of water in the gap between the bath and the wall, the formation of fungus, mold at the joints.

Silicone car

This sealant can be used during various technical works, but it is mainly used to replace gaskets in cars. It is highly resistant to engine oil, antifreeze, moisture. It tolerates high temperatures well and does not lose its qualities even after a few years. Due to the thick consistency of the composition, the process of applying the product can not be called complicated.

During work using this material, contact with gasoline should be avoided.

How to choose

Sealant is a simple and affordable grout that fills cracks, increasing tightness. Used independently at home, by professionals and in industry.

The scope is very extensive.

The scope is very extensive.

To choose the composition, you need to know where it will be applied, with what it is compatible, take into account the duration of the functions, resistance to external factors and the color of the processed parts.

Sealants are divided into acrylic, polyurethane and silicone. For each surface a different grout is used depending on the temperature differences in the room and other factors.

Kim Tec sealant is used as an insulator for windows, doors, an aquarium, etc. Its task is to prevent the penetration of damp, dust and extraneous odors. The main advantage is the ability to use indoors and outdoors for chores.

Black finish

Black finish

Compatible with glass, wood, metals, enamel and ceramics. Transparent glue will help in gluing the aquarium and food surfaces. Silicone rubber is heat-resistant and does not change under the influence of weather conditions.

The treated surface cannot be painted, but the manufacturer compensated for this with a color range of materials. There is a transparent, color and black silicone, which will last at least 10 years. The rubber mixture is safe for human life, non-toxic and does not require the use of protective equipment. For gluing the aquarium does not need special skills, due to the quick setting it will be ready in 30-40 minutes. Full battle will occur within a day.

Types of materials based on silicone

Hermetic mixtures are divided into two types - two-component and one-component. Two-component are used in industry, including food. The second subgroup relates to construction and repair work.

One-component are divided by composition:

- Acidic - basically contain acetic acid. They have an unpleasant characteristic odor, are universal in application and financially beneficial. The cartridge is indicated by the letter A.

Universal composition

Universal compositionThe disadvantage is the fact that this sealant cannot be used for non-ferrous metals, marble, cement and other alkali surfaces. It is capable of causing corrosive processes and corroding surfaces. The silicone base is colored and transparent, may have a black color. An example of such a silicone sealant is Kim Tec 101.

- Neutral - alcohol or ketoxime is the basis. Suitable for use with various surfaces. An example is Ceresit CS.

- Alkaline - amines are used for the manufacture. Designed for non-ferrous metals, marble and cement materials.

Silicone sealants are also divided as intended. Ceresit CS 25 is an excellent plumbing sealant. Designed for sealing water pipe connections, sealing plumbing devices in the bathroom.

Surface Sealant

Surface Sealant

A separate subtype is adhesive sealant, such as Kim Tec 101. It is used to work with glass substrates (window panes, etc.). This silicone is resistant to external factors, able to withstand heavy weight.

Composition for finishing an aquarium and other domestic needs

Composition for finishing an aquarium and other domestic needs

One-component silicone sealants have a variety of color variations. Ceresit 25 and Kim Tec 101 are usually transparent or white, but grout is available in different colors, including black.

Work with silicone - features

It is easy to work with silicone sealant. To start sealing the seams, you need a special gun for the cartridge with a silicone base. Open the package by cutting off the end of the spout, and putting on the dispenser in its place. To regulate the supply volume, the dispenser is cut as necessary.

How to work with a gun

How to work with a gun

For more information on how to work with silicone sealant, see the video:

Apply to clean, dry surfaces so that the silicone adheres to other materials.The exception is Ceresit 25, which is used in a humid environment. To remove the excess composition from the food surface, it is simply washed with a wet rag. Hands are easily washed with soap. The residues are removed before drying, otherwise it can only be cleaned mechanically. Use solvents to remove a small layer of Kim Tec silicone glue from the aquarium.

Removing Surplus

Removing Surplus

In fact, this is all that can be said about sealants. Remember about safety measures when applying. To protect expensive decorative elements, it is better to cover or paste over with special oil tape before starting work. By drying, the adhesive tape and other protection are removed.

Definition of high quality sealant

The quality criterion is part of the fillers in the base. The more silicone, the more durable the adhesive.

The highest quality is considered 100% silicone sealant. It has low shrinkage, long service life and high mechanical properties. Cost is higher than other products. But there are others, of less quality. During the manufacturing process, additives are introduced into the silicone that reduce the hermetic properties.

Silicone with a small portion of additives is also convenient to use, and its quality is slightly reduced. These include the black 101 sealants, as well as Ceresit CS 25, which is used with high moisture to prevent mold.

- If you weigh a standard tube with a clean silicone sealant (310 ml), its weight will be no more than 340 g. If this figure is exceeded, then fillers are added.

- If the cartridge does not have a cure type label, turn it upside down and squeeze it. Acidic mixtures smell like vinegar.

- If a solvent is added to the silicone, then when it is applied to polyethylene, the area under it is inflated and wrinkled. After weighing the tube, the solvent cannot be determined, because it is not inferior to silicone in density.

Silicone glue for sealing window frames

Tips & Tricks

If you carefully study the instructions for use and recommendations for the purchase of sealant, then the purchased product will last a long time and will bring great benefit:

As part of a high-quality sanitary sealant, silicone rubber must be

It has no unpleasant specific smell and poses no danger to humans.

When using the substance, one must act carefully and accurately, then the appearance of the room will not be spoiled. Before applying the sealant to a specific area, it is necessary to degrease it and dry thoroughly, since the product does not adhere to a wet surface.

A tube is inserted into a special gun, called a mounting gun, previously cut off with an inclination of slightly less than 50 degrees, a tip is put on it, and then the tool is squeezed. To obtain a neat seam, it is necessary to adapt to push the gun with the appropriate force. To avoid the penetration of excess funds, as well as to obtain an aesthetic seam, the edge of the joint is treated with adhesive tape, which must then be removed.

Use a damp cloth or sponge to remove excess sealant from the surface.

Then try to trim the seam with your finger or spatula.

When using sealant, it is important to know the drying time. After applying the composition, the top coat will dry for several hours.

Full drying will occur no earlier than in a day.

To make the composition dry faster, it is necessary to improve ventilation in the room. It is advisable to artificially double the air temperature. To speed up polymerization, you can spray water on the hardening joints

Removing the previous layer before applying fresh also contributes to faster drying of the composition.

To acquire a quality product, it is necessary to take into account the shelf life of the product, focus on the plasticity and elasticity of the product during temperature fluctuations, take an interest in the quality of adhesion (adhesion), compression of the product after the evaporation of the liquid. You need to find out how the material is stretched to a complete break.

In more detail about how to use silicone sealant correctly, the following video will tell.

Criterias of choice

TOP-20 of the best children's washing powders: a review and recommendations for choosing + Reviews

Ease of use is one of the important factors when choosing a sealing compound

A reliable sealant that firmly adheres to surfaces, protects seams and gaps, must have the following characteristics:

- Have high adhesion, do not peel off the surface

- To withstand the high temperatures characteristic of bathrooms

- To be flexible and withstand mechanical tension, elongation, load

- Have low shrinkage when drying

- Harden quickly in air

- Be convenient to use

- Provide economical consumption

- Highly resistant to biodefeats

In conditions when it is necessary to use sealant in an unheated bathroom in a country or country house, the frost resistance indicator acquires a high value.

The most common plumbing sealants are white and transparent, but from different manufacturers you can find up to 20 colors of the insulation mixture.

Scope of application

People are often interested in what parts of the bathroom need to be treated with sealants and how to choose the right tool in each case. We will understand this now.

First of all, you need to protect the cracks from water:

- near the bath or shower, where they border the floor and walls,

- the wall and back of the washbasin,

- between the floor and the toilet.

A universal remedy for this is silicone sealant. You can use compounds with polyurethane or MS-polymers. But acrylic is better not to use: the seams will quickly become worthless.

Adhesive sealants will replace regular glue.

You can use this property:

- when assembling sewers - they increase the strength of the joints,

- for processing the shower cabin - they fill the gap between the door and the tray so that during washing the water does not drain onto the floor,

- when decorating walls with tiles - if you want to glue tiles to metal, plastic, plywood, drywall, particleboard,

- for repairing cracks in tiles and cracks along doorposts, fixing the ceiling plinth - this task is better handled by an acrylic composition.

You can also use sealant as a grout: fill them with seams between the tiles. The connection will be more elastic and durable. If you want to revitalize the interior a bit, buy a colored sealant. You can choose a color that is contrasting with the tile or close in color, but different in shade.

Well-known manufacturers

Choosing colored sealants on a silicone or acrylic basis, it is better to focus on well-known manufacturers. Popular companies receive good reviews, care about the quality and usability of their products. There are many companies that produce several varieties of sealants in different colors at once. The most famous representatives are Accent, Germent, Ramsauer, Ilbrook, Moment, Ceresit, Soudal, Titanium, Macroflex.

Colored silicone

Titanium is a leader in the manufacture of building mixtures. The company produces silicone compounds in different colors for indoor and outdoor use. Titanium produces professional compounds based on silicone, acrylic, bitumen, polyurethane.

Ceresite is a no less well-known company in Russia that produces a number of different sealants of various colors.

Sudal produces world-class color seals. The company's products are harmless, manufactured taking into account all quality requirements of ISO 9001. From Sudal you can see sealants, adhesives, roof insulators. Among all the products, one can single out a universal neutral silicone composition for concrete, aluminum, PVC, acrylic.

Colored acrylic

Accent - high-quality acrylic sealant with excellent insulating properties. There are 5 varieties of product for different purposes. They help improve insulation, reduce heat loss, and fix door and window frames. For example, Accent 124 can be used for outdoor applications. It has good adhesion to concrete, but is also used for stone, tile, brick. Accent 128 is suitable for interior work, providing good thermal insulation.

Ilbrook - has a wide selection of shades. Sealant retains its color for a long time. Often used when working with glass, well suited for concrete and metal.

Each color sealant is suitable for its purpose. Before buying, you should consult with a specialist who will tell you the best color scheme. You should also independently check the quality of the sealant and its color in a small area.

Neutral silicone sealants are marketed by different manufacturers. They are classified by composition, purpose, color palette. The choice depends on the place and purpose of application. The purpose of the composition is indicated on the packaging. In most cases, sealants are divided into construction, automotive and special. They are available for indoor, outdoor, wet or dry rooms.

By purpose, silicone sealants come in several forms.

Plumbing and sanitary. This type of product is equipped with antifungal additives, they repel water well, therefore they are used in rooms with high humidity: bathroom, pool, kitchen, bathroom. The joints of pipes and plumbing equipment are treated with sanitary silicone. It has a high degree of adhesion, tolerates aggressive detergents, withstands high temperature conditions.

- Automotive. Used to replace automotive gaskets. Silicone repels water, engine oil, but contact with gasoline is not recommended. The sealant withstands temperatures up to +300 degrees, is strong and durable.

- Roofing This type of sealant has enhanced adhesion to brick, wood, bitumen, metals, plastic, ceramics and concrete. Indispensable in the processing of joints of tiles, for sealing chimneys, roof windows and other roofing works. It tolerates any climatic conditions.

- Construction. Neutral silicone sealant is used for various kinds of construction and repair work indoors and outdoors. It has good adhesion to gypsum, metals, plastic and so on. Resistant to ultraviolet, does not age and does not discolour.

- For work with brick and stone. This product is designed to perform outdoor work, is well resistant to weather conditions, tolerates temperature fluctuations, includes fungicides that stop the development of fungal formations. It has good adhesion to porous surfaces, it is used for grouting, joining stone, plastic, glass.

- Aquarium. Glue-sealant for glass does not contain harmful impurities, non-toxic. It has good adhesion to glass and other smooth surfaces. Used for gluing walls of florariums, aquariums, terrariums, vases and glossy windows.

This is not all types of work where silicone sealant is used. In everyday life, there will always be a miracle glue that can “bond” any surface.

Purpose, composition and properties

Sanitary sealant is universal, but due to the high cost it is more often purchased neutral.

Sanitary options are widely applicable for various purposes:

- for plumbing work,

- when laying pipes

- for processing joints and seams,

- to fill the gaps,

- when installing kitchen equipment,

- for processing window frames,

- for grouting tiles

- for insulation during electrical and repair work.

Sanitary sealants contain special additives that protect against mold and other organic deposits, for example, having a bacterial nature. They increase the cost of material, but are simply necessary in places with high humidity. Also, silicone products are quite resistant to chemical attack.

Due to such additives, sanitary sealants can not be used in those works that are related to products, drinking water and animals. This is the main difference from the universal tool.

Sanitary silicone sealant has the following composition:

- silicone rubber - makes up the bulk

- hydrophobic filler

- plasticizers for elasticity,

- thixotropic agent, making the material less viscous,

- fungicide that provides protection against fungus,

- adhesion enhancing primers

- pigment coloring

- catalyst.

Thanks to additives, silicone sealants are resistant to ultraviolet radiation, withstand frosts up to -30 ° C, have high elasticity, are not afraid of temperature changes and atmospheric precipitation. Therefore, they are excellent for outdoor repairs, glazing of building facades and greenhouses.

For home use, it is better to purchase sanitary sealants in small tubes. After opening the package, the tightness conditions are violated, and the remaining unused silicone will dry out or deteriorate in quality over time. If necessary, it is better to buy fresh. With large-scale repairs, for example, replacing pipes and plumbing in the bathroom, you can buy a larger tube, it will be more economical. For convenience, you will have to purchase a special gun, which is characterized by reusable use, but cheap models quickly fail.

Other brand products

To maximize customer satisfaction, the American manufacturer produces specialty sealants in batches and in the form of individual products. These include:

- Penetrating silicone with high fluidity Abro 3200. Actual use of silicone sealant for the repair of glass, headlights, car accessories, bonding metal, ceramics, wood, rubber. Advantages: temperature from -65 ° С to 206 ° С, increased fluidity, deep penetration, vibration and heat resistance, neutral to aggressive liquids.

2. Liquid sealant for radiators SL-624, containing bentonite clay. It is used to eliminate leaks in car cooling systems, including aluminum. Allows you to perform temporary repairs of radiators, BCs, cylinder head gaskets, heating systems. Packing - 325 ml. Also, the product is available in the form of a dry powder (20 g), which must be filled directly into the radiator of the machine.

3. Polyurethane sealant for glasses UR-3000. It can be used for bonding windshields, sealing joints, gaps and seams from moisture. Suitable for exterior facade work. Effectively adheres to glass, ceramics, plastic, wood, stone. The time of complete solidification is 3-4 hours. After solidification, the surface can be painted. Packing - 300 ml tube.

4. One-component structural silicone SS-9895 for bodywork. Creates a flexible waterproof layer on the treated surface, adheres well to metal, stone, concrete. Provides absolute sealing, does not cause corrosion processes. The composition is not toxic, does not have a specific smell. It is realized in tubes of 310 ml.

5. Aerosol copper sealant Abro CG-418-R. A scope - sealing automobile and motorcycle gaskets, including cylinder head gaskets, exhaust pipes, carburetors. Belongs to the category of high-temperature compositions, contains copper dust. Well prevents the extrusion of gaskets during assembly of components and assemblies.

Another popular Abro RS-425-CLR product is liquid rubber rubber spray. A scope - car repair, water supply systems, pools, door hatches. It eliminates leaks well, forms a moisture-proof elastic coating, fills voids and small cracks.

To effectively clean the metal surface of Abro silicone sealant, grease, glue, varnish, paint, it is enough to spray the agent, leave for 5-10 minutes and remove the old coating with a spatula.

Preparatory work

Sealants for household purposes are available in the form of tubes with elongated spouts. Some masters, in order to create more accurate seams during application, additionally purchase special nozzles on the tubes.

Nozzles for the tube are indispensable in cases where it is necessary to seal the area that is in sight: for example, the joints of the tile between the floor and the ceiling, the places of the pipe for the heated towel rail

In addition to the sealant itself, it is necessary to prepare a set of materials and tools before work:

- masking tape with a width of 20-30 mm,

- white spirit, acetone or any other fat-soluble liquid,

- spatula, the width of the blade of which is selected depending on the thickness of the seam,

- cotton napkins or clean rags to eliminate flaws in the work.

When working with sealants, which contain aggressive components, it is additionally worth taking care of the purchase of personal protective equipment: a respirator, glasses and gloves.

The surface before applying the sealant must be prepared: clean from dirt, eliminate all irregularities. At this stage, you need to carefully inspect the walls for mold. If this is found, you need to fix the problem by treating the area with a disinfectant.

If there are old seams on the treated area, they should be thoroughly cleaned of silicone residues, otherwise they will not allow the sealant to lie evenly, filling all voids

The prepared surface can only be degreased by wiping with a cloth soaked in acetone or alcohol, and dried by thoroughly wetting with a piece of cloth. Using a solvent, degrease metal parts.

To protect the treatment site from sloppy blots that can happen even with an experienced craftsman, masking tape is glued along the alleged seam.

Ways to eliminate minor flaws

There is nothing complicated in adjusting the finished seam. To do this, using a narrow spatula, they press the material along the applied line. Such manipulations will make it possible to better press the sealant to the surface and make the joint smoother.

When planning to align the seam with a spatula in order to minimize the effect of “toffees”, the working canvas of the tool should first be moistened with water

To remove sealant residues that “knock out” beyond the seam, you only need to wipe the surface with a cloth moistened with water. If this doesn’t help, you can use white spirit, the Antisilicon organic solvent or the specially developed Foam-840 wash.

After completion of work, the masking tape is peeled off. If the work was carried out without gloves, hands are thoroughly washed with soapy water.

After making sure that the applied composition is evenly and accurately distributed, it remains only to wait for it to completely dry. It will take at least a day. But it will be covered with a thin film and the composition will cease to be sticky after half an hour. If the acid version is used, then before operating the bath, it is necessary to carefully ventilate the room.

Acrylic

Acrylic sealant for a bathroom is cheaper than silicone, but it serves less time. Its properties:

- withstands temperature extremes,

- does not fade

- characterized by high adhesion to various materials,

- on top it can be coated with paint, varnish, putty (unlike silicone),

- does not have elasticity, it cannot be used for joints with a risk of deformation,

- hardens within 24 hours.

Acrylic sealant is convenient to use for:

- filling the space between stone, brick and concrete surfaces,

- stickers of the ceiling plinth in the bathroom, while it will smooth out the roughness of the walls,

- "Grouting" wide joints.

Acrylic-based products do not always have a water-repellent effect. When buying, you must definitely check whether the product is suitable for the bathroom.

Polyurethane

A polyurethane based sealant is used to seal joints between glass panels, wood elements, stone, concrete, and ceramics. Its properties:

- hardens quickly

- often used as glue,

- means can be transparent, white and color,

- characterized by durability and elasticity,

- You can cover the reconciliation with paint or varnish.

The disadvantage of polyurethane sealant is an aggressive effect on the skin with direct contact. When working with him, be sure to wear gloves and a mask.

Other species

In addition to the listed main sealants, the following are also available:

- silicone-acrylic - contain both polymers and combine their properties,

- aquarium - acidic silicone sealants without additional components, which are used for gluing glass parts, sealing showers, sealing aquariums.

As additives, sealants may contain:

- extenders (expanders) and fillers (quartz chips, chalk) - to fill wide joints,

- organic solvents

- dyes

- rubber - for plasticization instead of silicone,

- mineral oils.

The properties

Sealing joints, cracks, creating a movable joint. Due to the fact that the material is elastic, the integrity of the seams is not violated.

- The sealant is used in the temperature range from -50 to +200. On sale there are heat-resistant masses that withstand heating up to +300 degrees.

- It is not affected by external factors, including aggressive ones. As a result, it can be used in any conditions.

- The hardened sealant has high moisture resistance.

- An important characteristic is the high adhesion properties of the silicone sealant to almost any material.

- Fungi and mold do not infect silicone.

Option to use sealant

The advantages of the universal composition are obvious, but there are also disadvantages, among them:

- It is extremely difficult to handle wet areas. A specific paste-like mass simply rolls along such a surface without being fixed.

- Not all sealants can be painted.

- They do not provide sufficiently reliable sealing of surfaces made of polyethylene, fluorine plastic, polycarbonate.

But these flaws cannot be found in professional building silicones. They contain organic components, mechanical fillers. But the price of such funds is quite high.

Scope of use

In fact, almost all stages of repair work require the use of sealants.

During outdoor work, they are necessary for:

- sealing gaps and joints of window-door blocks,

- fixing plates made of marble or granite,

- sealing joints during roofing,

- sealing glass constructions,

- seals joints vinyl cladding.

The range of application of these funds during internal work is no less wide:

- sealing joints during the installation of suspended ceilings,

- sill seams,

- sealing of various parts,

- sealing plumbing pipes, sewers, showers, mirrors in the bathroom.

It is impossible to list all the possible applications for the sealant. Specialists working with this material do not tire of finding new methods for its use. This also applies to private masters who come up with non-standard ideas for the use of silicone sealants.

Bituminous

Compared to analog black sealants, it is considered more modified. It contains metallic pigment, which makes the material more durable and gives it a light steel shade. It is characterized by super resistance to external damage and moisture, elasticity, excellent adhesion to dry and wet surfaces.

It is used to seal cavities and grout joints in the roof. Suitable for repair and construction work in the drainage system, chimney, ventilation. When choosing, it is important to consider the fact that this material is highly toxic. Therefore, it is not recommended to use it for repair work indoors.

For granite

Sealants for marble and natural stone are slightly different from other grouts. They are simpler to operate, easily penetrate into cracks, seams and pores of a stone. Moreover, the structure of such materials is more durable and flexible. In addition, it is convenient to work with such a sealant - during application it will lay down in a thick seam.

Such materials were loved by consumers for their excellent performance: resistance to moisture, dust, pollution. The product is non-toxic and does not emit odors when heated in the sun. You can no longer be afraid of mold: fungicides, which are part of the material, prevent the appearance of fungus.

The use of special sealant ensures a longer service life of stone and marble coatings. It is equally well suited for both indoor and outdoor use.

Rubber

This material is produced on the basis of siloxane rubber. Such sealants are used for grouting wood and glass panels. Many craftsmen often use them as an alternative to grouting ceramic tiles.

There are two types of rubber sealant.

- Acetate for surfaces made of smooth materials. It is characterized by a strong, quickly weathering odor.

- Neutral for interior use. It has excellent adhesion to enameled, glass, wood and ceramic surfaces. When choosing, it is important to know that in comparison with similar tools, it has lower strength.

Types of silicone based sealants

Hermetic mixtures are divided into two types - two-component and one-component mixtures. Two-component are used in industry, including food. The second subgroup relates to construction and repair work.

One-component are divided by composition:

- Acidic - basically contain acetic acid. They have an unpleasant characteristic odor, are universal in application and financially beneficial. The cartridge is indicated by the letter A.

The disadvantage is the fact that this sealant cannot be used for non-ferrous metals, marble, cement and other alkali surfaces. It is capable of causing corrosive processes and corroding surfaces. Suitable for gluing an aquarium. Silicone base color and transparent, may have the black Colour. An example of such a silicone sealant is Kim Tec 101.

- Neutral - alcohol or ketoxime is the basis. Suitable for use with various surfaces. An example is Ceresit CS.

- Alkaline - amines are used for the manufacture. Designed for non-ferrous metals, marble and cement materials.

Silicone sealants are also divided as intended. Ceresit CS 25 is an excellent plumbing sealant. Designed for sealing water pipe connections, sealing plumbing devices in the bathroom.

A separate subtype is considered an adhesive sealant, such as Kim Tec 101. It is used for working with glass substrates (aquariums, window glasses, etc.). This silicone is resistant to external factors, able to withstand heavy weight.

Surface Sealant

One-component silicone sealants have a variety of color variations. Ceresit 25 and Kim Tec 101 are usually transparent or white, but grout is available in different colors, including black.

Positive features

This composition has a number of undeniable advantages:

- UV rays do not adversely affect the composition,

- the substance is resistant to weathering,

- quickly and reliably grabs plumbing surfaces,

- tolerates low and high temperatures (from -50 to +200 degrees),

- it is allowed to apply sealant on a cold and heated surface,

- prevents the growth of microorganisms and the appearance of fungus, mold,

- elastic.

Where to use?

Plumbing silicone sealant is used in rooms with a high level of humidity. Using it, seams are sealed between materials of different structures (for example, between ceramic tiles and a metal / plastic pallet).

If the plumbing is made of plastic, then in this case, give preference to a neutral type of sealant.

Plastic pipe insulation

Packaging

This composition is sold in tubes with a capacity of 280 to 310 ml, made under the gun. Less common are aluminum tubes and file packages. The tube has a convenient “spout-syringe” for application, from which the solution comes out with a thin strip.

Before you buy the composition, look at the packaging. It indicates how and under what conditions the substance is used. As for the color palette, the silicone sealant can be transparent, white or colored (pink, yellow, brown and so on). The color is selected based on the tone of the surface on which the substance is applied. The most popular is a transparent composition.

Keep in mind that the silicone compound in open form retains its properties for only a few days, so it is recommended to seal it reliably after use.

How to apply?

So that the silicone does not lose its elasticity and does not crack, apply the composition correctly:

- Start with surface preparation. It is thoroughly cleaned of dirt and rust (if any). Next, the base is ground and degreased.

- Then the seams are sealed by first inserting the cartridge with the solution into the gun and pulling the trigger.

Work with a construction gun

When applying the composition to the seam, make sure that the line is continuous. If the composition is in an area that does not need to be processed, remove it with a cloth / paper.

- Five minutes after application of the composition proceed to the formation of the seam. This is done manually after putting on rubber gloves.

Touching the sealant with your bare hands is contraindicated, since the composition contains acid.

- If surplus remains on the surface, they are removed with a cloth. If you need to remove excess after hardening, use solvents.

- It is necessary to form a seam within fifteen minutes, since during this time the solution grasps.

Observe the seam width within 5-30 millimeters. The depth of the applied layer should be twice the width of the layer. If you need to make a deep seam, use a sealing tape, which is fixed with silicone.

Be careful when using the substance with brass, lead, synthetics and copper. When silicone reacts with them, a harmful substance is released.

On metal pipes

Varieties of plumbing sealants

By the chemical composition there are such types of sealant:

- Universal. The basis is acid, so an unpleasant odor is released during operation. The positive aspects of this composition include low cost.

Such a composition is not used in conjunction with non-ferrous metals, cement surfaces and marble.

The negative aspects include a color change and a decrease in strength when exposed to aggressive substances.

- Neutral The composition of the substance includes alcohol / ketoxime. Use its composition with any surfaces. Applied when installing pipes.

Note that with the interaction of acids and alkalis this sealant does not change color, the strength indicator does not decrease. However, the cost of such material is high.

- Alkaline The basis of the substance is amines. Alkaline sealants are used in rare cases.

The composition is selected for each material

The most popular sealant is “Moment”

Such a composition is widespread in many areas.“Moment” is used when installing sewer plastic pipes, gluing surfaces, sealing joints.

Note that such a composition is not recommended for structures made of natural stone. Plumbing “Moment” is not suitable for concrete / cement surfaces, metal sewer pipes.

“Moment” contains silicone, silicon dioxide, an antifungal supplement, and acetoxysilane. “Moment” silicone sealant is a sealing substance that can be firmly set with other materials.

The manufacturer “Henkel”, in addition to the plumbing “Moment”, produces a universal one, which is suitable for the installation of water pipes, automotive structures, and sealing door and window frames. It is produced in white or transparent color.

The company also produces the Moment neutral sealant, which is suitable for sealing plumbing pipes and mirror surfaces. Use it in shipbuilding and mechanical engineering.

The advantages of “Moment” include:

- high elasticity

- wide range of applications (suitable for sealing plastic pipes and other surfaces),

- The “moment” is quickly set,

- resistance to temperature extremes and moisture (therefore, it is used when installing sewer pipes),

- low price.

What to look for when choosing?

When choosing a sanitary sealant, pay attention to the following nuances:

- Shelf life. Buy only the composition that is not expired. After the expiration date, the sealant loses its properties.

- Packaging. It should be holistic, without cracks, bruises.

- Appointment of the composition. For example, if you need a sealant for sewer pipes, then you need to purchase the appropriate composition.

The modern market offers a huge amount of means for sealing joints and seams, but a special niche in this variety is occupied by Henkel Sealant Moment, some of which are also used as glue. The main features of this material include the optimal composition, ease of use and a variety of species designed for use in all areas of life: from leaks in the aquarium, sealing the mirror in the bathroom, to sealing joints in shipbuilding.

A little about the manufacturer and brand

The product line, manufactured under the name Moment, was the result of the fruitful work of specialists from Henkel (Germany), which has been a leader in the market of chemical products for domestic and industrial use for 130 years. Being the first Henkel allows the use of the latest equipment, the constant search, research and modernization of technologies, their successful implementation in production.

A wide developed network of representative offices, production aimed at maximum environmental protection, strict quality control - these achievements of the company serve to make the lives of consumers more comfortable, openly conduct dialogue with them and improve. As a result, more than 200 types of products, most of which are moment adhesives and sealants. The range includes mounting foam and self-adhesive tapes.

Types of sealant Moment and brief characteristics

The company manufactures one-component sealant of two types: silicone and based on acrylic water dispersion. The latter is characterized by frost resistance and adhesion to all types of surfaces, including porous. The main disadvantage: it is not used in places subject to constant exposure to moisture. The produced color is white.

Silicone sealant is made on the basis of rubber polymer, which allows the elastic mixture to harden immediately at room temperature. Therefore, to keep the material viscous, Moment sealant is sold in special plastic tubes with dosing nozzles. Available in capacity of 85 (on a blister card) and 280 ml. Based on the scope, it is divided into construction, special and automotive.

Packing on a blister card (85 ml)

Types of Sealant Series Moment:

- neutral - instead of vinegar, it contains alcohol or ketoxime, which makes the smell not so pungent, suitable for indoor and outdoor use, is used in shipbuilding, for sealing freezers, color variations: transparent, white,

- universal (or acidic) - is made with the use of acetic acid, has a specific smell and causes corrosion when interacting with non-ferrous metals, marble and cementitious substances containing alkali. It is marked with the letter “A”, it is not painted, it is available in two color variations - white and transparent. Suitable for indoor and outdoor use, cheaper than neutral.

Henkel manufactures a silicone emulsion based sealant (Silikotek series) that provides triple protection against mold. Warranty - 5 years. If incomplete solidification is removed with a dry sponge or cloth. At the end of work, the tool is washed with water. Neutral, white, odorless. It is not applied as glue.

Acid free

Sealants with a rich component composition

Henkel produces yet another silicone sealant that differs in its characteristics and component components. It is called Moment Germent and includes a series for domestic and professional use. It differs by the addition of fungicides - substances with anti-mold properties. The volume of the tube is 85, 280, 310 and 600 ml. It is divided into universal (with vinegar) and neutral (without it). In addition, it includes the series:

- White Premium - consists of silicone (acetoxy), has higher moisture resistance,

- high temperature - it is made on the basis of acetoxy and sodium silicate, it is oil and gas resistant, high temperature resistance (tolerates heating up to +315 ° C), after hardening it retains elasticity. Color - red-brown,

- sanitary - it is applied at glazing of showers, as glue at repair of sinks, bathtubs. The color is white and transparent, hardens “before low tide” in 20 minutes, contains acid. Not used for structures made of natural stone and rusty surfaces,

- for an aquarium - ideal for sealing painted plastic and glass structures that are susceptible to constant vibration, moisture resistant, neutral. Given the specific application, color sealant only transparent.

Also, the moment of the Herment series includes gray sealants based on polyurethane (PL-20 and PH-40) with a volume of 310 ml. These types are used for grouting highly mobile joints, act as glue for tiles. Remain resistant to acids and salt solutions, cleaning products and water. Disadvantage: they fade under direct sunlight and lose their elasticity over time.

For sealing and adhesion of various types of joints and surfaces, universal multi-purpose adhesive based on FLEXTEC polymer is used, in which silicone, polyurethane and acrylic types of sealant are combined. It hardens under the influence of moisture. The composition is neutral (alcohol). White colour. Serves for sealing joints in air conditioning systems, window frames, between building blocks, brick walls, and is used for laying mosaic tiles.

The video below contains summary information on silicone and acrylic adhesive sealants, which will allow a comparative characterization of these compounds, to clarify for which surfaces to use them. and how to avoid interaction.

Sealants have drawbacks: both neutral and universal material based on silicone masses cannot be painted; in conditions of low temperature and high humidity, solidification takes 4-5 hours or more.

Despite the listed variety of models and their minor drawbacks, we highlight the advantages that are common for one-component silicone sealants, including those from the Moment series:

- high adhesion to any materials,

- water resistance and elasticity,

- resistance to aggressive environments, mold, fungus, UV rays and sudden temperature changes (operating range from -60 to +350 ° C),

- used as glue or for sealing joints, increasing their aesthetic appeal, eliminating drafts,

- strength, resistance to abrasion, which allows them to be used on moving parts.

Thanks to these features and the continuous improvement of Henkel products, the Moment brand has become recognizable all over the world, and with the phrase silicone sealant, a chain of associations immediately arises: quality, reliability, durability. If you add an affordable price to this, the advantages of Henkel products become even more obvious.

However, do not forget about your health and do not try to save. Choose a neutral, acid-free sealant, even though it costs more. Follow the instructions for airing the premises and do not forget about other precautions.

Construction is an area where there are many special tools and materials that are used in a limited range of tasks. But there is such a universal remedy that can be used in a huge number of operations - and this is silicone sealant.

Assortment of silicone large

What it is?

It has become a substitute for outdated bitumen-based mixtures, all kinds of homemade mastics, putties. This composition is able to glue together different elements and qualitatively seal joints and seams.

Silicone sealant is a dense, viscous mass; it is used for insulating joints, gluing surfaces and sealing joints. After drying, the material gains moisture resistance, does not allow moisture and other undesirable substances to penetrate into the seam of the treated structure.

Composition

In the composition of silicone, there are such elements:

- Silicone rubber is the basis of sealant.

- Amplifier, it gives the composition strength after drying. Amplifiers determine the level of viscosity.

- Adhesion primer - a component that is responsible for adhesion to the application surface.

- Plasticizer, he silicone. The main task is to increase the elasticity of the material.

- Vulcanizer. It is this component that is responsible for such a characteristic as solidification. It turns a pasty composition into a plastic rubber substance.

Seal between concrete slabs

Additional components can significantly expand the scope of use of building sealant. Among the most common:

- Dyes. Silicones can be black, white and other colors. Pigment is added during the production process, which helps to use it later to mask seams and cracks on surfaces of any color.

- Mechanical fillers. For example, sand, glass / quartz dust - these components improve the adhesion between silicone and the surface of the application.

- Fungicides. They fight and prevent the development of fungi, mold. This is true if sealants are used in rooms with high humidity.

One component

These are most often used in domestic conditions. Using them you do not need to think about the proportion of mixing, because they are immediately ready to work. Sold in sealed tubes, foyle bags, which are capable of storing the composition well. They harden upon contact with air, but only on condition that the layer does not exceed 1.5 cm.

Multi-colored one-component sealants

They are acidic or neutral. Acid have such features:

- The composition gives off acetic acid, so it can not be used on metals, since the sealant can cause corrosion.

- Its price is affordable.

- Labeling of these sealants is “A”.

- Before applying to any surface, it is better to check the acid reaction, because some may contain elements that begin to interact with acetic acids, and this will lead to an unexpected reaction.

Neutral silicone sealant is universal, because ketoxime or alcohol acts as a hardening component in it. Features:

- Withstand elevated temperatures, up to +300 degrees.

- It can be used in the process of building baths and saunas.

- It features a high level of bacterial protection.

- Fairly high price.

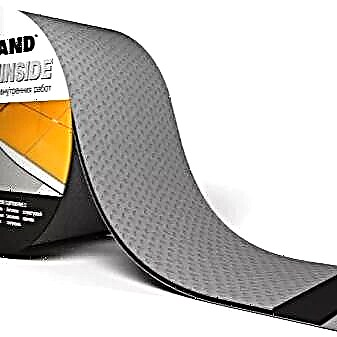

Tape

It is made on the basis of butyl rubber, this makes it resistant to low temperatures and ultraviolet. Excellent stickiness of the material simplifies the operation of sealants. They are popular in the field of roofing, and are also indispensable during the installation of thermal insulation, eliminating cracks and rusty coatings.

Popular brands

Multipurpose composition recognized as one of the market leaders among black sealants Abro based on silicone. It is used during installation or replacement of automobile gaskets. I fell in love with consumers because it takes a good shape, tolerates shear, tension and compression. Resistant to gasoline, various automobile oils, brake fluid, antifreeze and moisture. It can be applied at high temperatures (260 ° C).

Black sealant-seal of the brand is no less demanded Felix.

It is also common in the automotive field and is necessary for sealing the following elements of a car:

- glass

- dashboards

- decoration panels

- hatches

- headlight

- sidelights,

- turn and brake lights,

- body body parts.

Suitable for use outside, inside and under the hood of an automobile. It tolerates low and high temperatures (from -75 ° C to + 399 ° C).

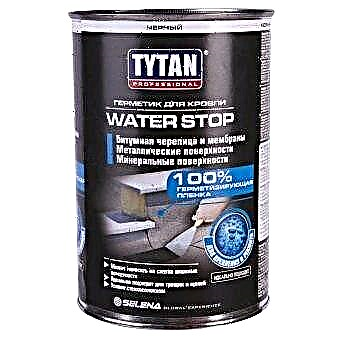

Many consumers choose Polish bitumen sealant for roofing Tytan black color. Made on the basis of rubber, it is characterized by high ductility. That is why it is most often purchased for puttying cracks and seams. It is suitable for surface treatment of materials such as corrugated metal, sheet metal, tile, bitumen. Thanks to the thixotropic structure, it is convenient to use - it does not drain from the tube when applied.

About how to distinguish sealant from the original manufacturer Abro from fakes, is described in the video.