Support poles are the main element of the supporting frame of any fence. They are made of brick, stone, metal and so on. No matter how strong the material, the environment in any case has a negative effect on it. The tops of the supports can rust, crumble, rot (in the case of wood). To protect them from damage, caps of various kinds are used, installed directly on the fence posts.

Caps for fence posts: what is it and why are they needed

The lid mounted on the fence post completes the construction of the fence, giving it an exemplary look. The main function of this part is to protect the upper part of the fence from the influence of the external environment and destruction. Caps for pillars are made mainly of metal and concrete. The reasons for installing caps on the fence are as follows.

- The new fence built on the site seems incomplete and looks less attractive if you do not install decorative caps on the fence posts.

- Designs protect the fence from rain, snow, hail and ice. A fence built of porous materials such as brick and natural stone is always subject to these influences. Caps reliably protect it from natural factors.

- The installation of special caps for lighting the territory makes it possible to create original lighting effects.

What are the requirements

Protective caps for poles, bought ready-made or made independently, must meet a number of requirements:

- symmetry and conformity to the shape and size of the supports,

- declared angle of inclination (checked using special devices),

- the presence of a frame overhang, its tight abutment to the surface,

- packaging integrity, you should carefully check when buying,

- compatibility with additional accessories of the original design (span bars, podium for a flashlight).

Intake Cover Functions

After the construction of the fence there is a problem of its protection from the aggressive action of precipitation. Depending on what material the fence is made of, appropriate intake caps should be selected. The headings for the fence posts can perform protective, aesthetic and support (for additional lighting) functions.

Protective function

Covering the tops of the fence supports, caps protect the material from which the fence is made. It is a reliable protection against moisture. Thus, brick and stone, having a porous structure, can lose their stiffness, crumble, and, ultimately, collapse. The materials from which the covers are made on poles can withstand the ingress of any precipitation: rain, snow, hail and frozen ice. The design configuration is such that liquid penetration to the main structure of the fence is practically excluded. The cap on the fence is selected depending on the racks and the fence and can be made of several types of building materials:

- concrete,

- natural stone

- plastic,

- metal (stainless steel, galvanized steel, tin),

- ceramics.

These materials are resistant, durable, and the metal is not susceptible to corrosion.

Decorative meaning and lighting

The cover element of the fences is not only protection, but can also be part of the design plan of the owners of the site. These details give the hedge completeness and grace. Among the wide range offered by manufacturers, you can find caps for any fence posts that match the overall landscape design with a pattern and color. They can be combined with roofing, gazebos, decoration of the recreation area. To create a general beautiful view of the territory, you can choose caps of the following type:

- imitation tiles

- imitation of scales

- pitched roof analog (in shape),

- simple cone

- pyramid,

- hemisphere

- decoration with ball or wrought iron elements.

In combination with such decorative elements on the posts, the fence will organically complement the general appearance of the site, giving it a noble appearance.

The cap on the fence post serves as a reliable support for installing fixtures on it. Such a solution will provide coverage of the entire territory of the site and the surrounding area, which is also important for safety. The main task is to choose the right type of lamp. Lighting elements are divided into two main groups:

- self-contained luminaires that are charged from a battery powered by photocells and do not require additional wiring,

- luminaires connected to an external network (12, 220 volts).

For the installation of lighting, concrete or metal caps are suitable, on which the lamps are mounted vertically.

Varieties

The heads that are installed on the fence tables for decoration and protection, depending on the material used, can be divided into several groups:

- metal caps. Apply tin, galvanized steel or stainless steel,

- plastic caps

- made of concrete,

- made of stone

- ceramic covers.

Fiberglass Fence Caps

Nowadays, umbrellas for fiberglass fence posts come to replace heavy brick and stone. Modern high-tech materials - fiberglass and plastic ABS - are the best solution to implement any design ideas.

Lighting devices inserted into such lugs do not get wet and perfectly withstand mechanical loads. In fiberglass caps, fluorescent lamps can be used to provide the owner with energy savings (up to 80%). The material consists of fiberglass (70%) and polyester resins (30%). The fiberglass fence cap is distinguished by the following qualities:

- strength,

- ease,

- flexibility and elasticity

- UV resistance. Colored caps do not lose quality and color depth,

- lack of corrosion

- water resistant

- resistance to temperature extremes (-50 ... + 80 degrees),

- wide range of colors.

The range of fiberglass tops is huge, there will always be an option that will be both convenient and beautiful. Products are available in two versions: matte and glossy.

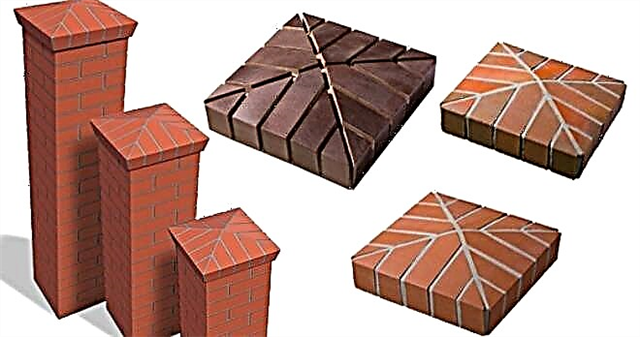

Brick Caps on Pillars

This kind of caps on the fence can be distinguished in a special group. These products look very impressive, so their cost is quite high. Caps on the fence made of ceramics, you can choose almost any color, which will be organically combined with the surrounding landscape. Brick pillars decorated with ceramic tops look stylish and beautiful. Clinker brick tolerates frosts up to 100 annual cycles, well retains its original appearance and is characterized by weak water absorption. Products are fragile enough, therefore very careful transportation is required.

Stone covers on fence posts

Today, there are many blanks on the market for fence posts made of artificial stone (lithium). Pleasant texture of the material, a variety of colors make these caps widely in demand. Stone heads successfully perform their functions to ensure the safety of support pillars. In addition, artificial stone can be chosen for every taste, depending on the type of structure, type of paving slabs or other type of paving surface.

Concrete

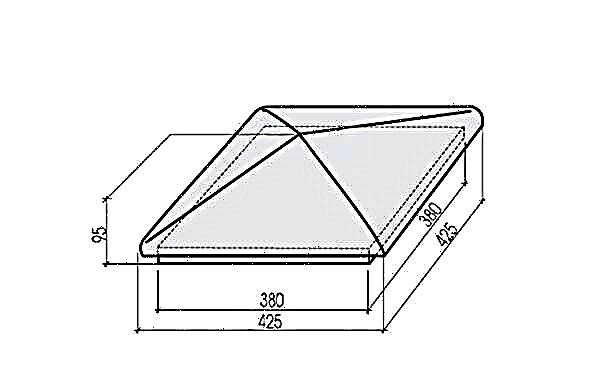

Caps made of concrete are often called a protective lamp, which fully reflects its functions, as well as a tip, fungus or head. Two factors provide a protective effect:

- the outer sides have an inclined profile, which provides a full flow of water,

- the dimensions of the concrete hood are significantly larger than those of the others. This increases the degree of support protection.

The nuances of using concrete covers

To obtain durable concrete covers, plasticizers and fiberglass, as well as anti-frost additives, are added to the base material. Manufacturers produce products with the inclusion of color pigments, getting multi-colored blocks. The blanks can be coated with the paint in which the facade of the house is painted. Over time, it will need to be updated regularly. Concrete tops are easy to mount on their own, they are original, but there is one limitation. The concrete cover is not suitable for metal fence posts, so it is never mounted on such supports.

Metal caps on the fence

Caps on the fence of metal are made hollow. This simplifies their installation. Materials - stainless steel, galvanized iron - perfectly perform a protective function. They are durable and not subject to corrosion. Hollowness does not affect the strength of products, but significantly reduces their price. The comparative ease of the blanks makes it easy to transport and assemble.

Visors that are mounted on fences are another protective element made of metal sheet.

Wood covers

Tops made of wood, as a rule, are installed in order to save money, for a short period of time and have a decorative purpose. Wood, as a material, cannot protect the fence from moisture, snow and other natural phenomena. The main advantage of wooden covers is the ability to make them yourself. This requires only desire, patience and the necessary set of tools.

Manufacturing methods

Metal products for supporting pillars are made by stamping, bending and welding.

If desired, the simplest cap of steel sheet can be made independently. After measuring the upper surface of the support column, a cap drawing is made, according to which a scan is cut. Then the edges are unbent, the product is assembled, fixed and painted.

Stamping

Roof tops are made by stamping and bending. In the production process, it is done so that the number of rebate locks (seams) is as small as possible. This is necessary in order to avoid even minimal penetration of moisture into the structure, which can cause damage to the support.

Bending

Forged protective caps on poles are made by cold forging and bending. The materials are steel sheet, round and square bar and steel strip. The cap is made of steel sheet. The blank has the form of a cone or a four-pitch roof. A bar is used to make decorative elements, like a steel strip. Forged elements on caps look beautiful, but are still subject to corrosion.

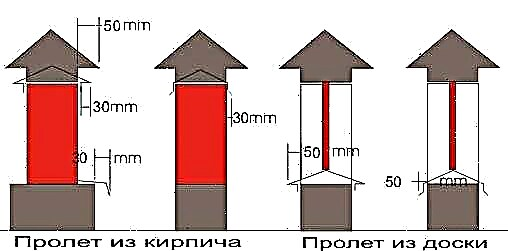

How to attach caps to fence posts

The fastening of the protective structure to the support depends on the type of protective cover. For installation, you should prepare a small amount of cement mortar, glue, screws, bolts that will be installed in the elements of the column. Several points are important:

- when installing the cap on the laid adhesive, it must be ensured that the product protrudes beyond the boundaries of the support (so that the adhesive is not washed away by precipitation),

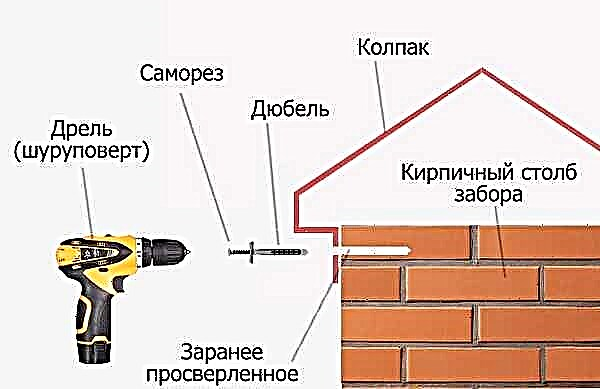

- galvanized steel caps fixed with dowels,

- applying any other installation technology, the main rule should be observed - ensuring the tightness of the seam after installing the cap.

What are the forms of protective caps for fence posts

Each owner seeks to make his site special and tries to make a hat on the fence with his own hands. To become the owner of an interesting site, there is nothing else left but to make the caps yourself. However, even unique caps on the most original fence fall under the general gradation. Several forms can be distinguished in form.

- "Tile". Reminds a roof according to drawing. Caps will harmonize well with brick supports. Columns decorated with “Tiles” of the right shade and size will really decorate the site.

- Roof construction. The form is suitable for a fence of any kind. It has various colors and sizes.

- Concrete covers gable.

- "Jellyfish" is a form of metal jellyfish.

Custom plugs

Unusual forms include samples:

- "Star". The top is in harmony with the fence of complex design,

- corner plug for several supports,

- "Rectangle". Nozzle for a site with a geometric design,

- "Diamond". Ideal nozzle for fixtures.

In the pursuit of originality, you can make caps with your own hands. Caps on poles made by hats and complemented by decorative elements will decorate the site to the envy of neighbors.

Protective cover design

The selection of caps for the fence is the first step in a new design project. Depending on which finials were selected, the following steps will depend. Using metal products, you can decorate them with forged elements and original inserts. Caps made of plastic themselves come in different colors, they can be selected under the leading color scheme of the site.

Protective structures can be of various shapes and designs. Nowadays, an abundance of materials that differ in a pleasant texture and original color allows us to show all our talents in this area.

General information

The main reasons to put covers on the fence posts:

- A fence plug is required to protect the brick pillar. Caps protect supporting structures from the negative effects of rain and icing.

- Decorative cap function. Without installing covers on the fence, pillars made of brick look ugly.

- Security function of the cap. Only one type of tip on the support of the fence - in the form of peaks - can scare away uninvited guests trying to climb over the fence.

- The top of the fence is a good basis for the installation of lamps and other decorative elements.

Especially protection is required for fence columns made of stone. This is a porous material, because it is much more susceptible to negative environmental factors.

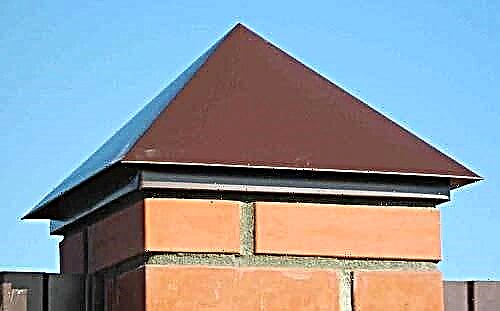

The photo shows the fence of a private house with brick pillars.

Types of protective covers for posts

Even the simplest tops on the support posts have a number of parameters that need to be considered when choosing them. They can be made in various forms:

- Simple - in the form of a cone.

- Sloping roof pads.

- In the shape of a pyramid.

- In the form of a hemisphere.

- Decorative designs decorated with various elements, for example forging.

In addition, there are protective covers for the fence, imitating metal or wood.

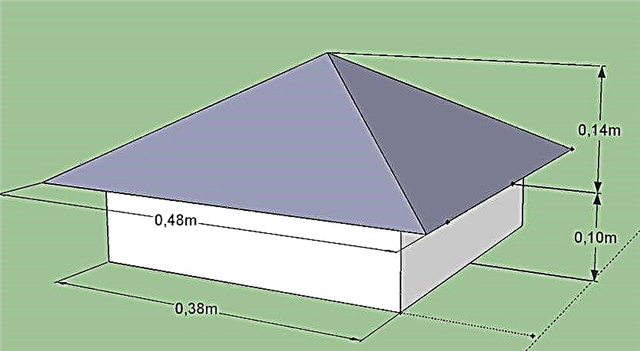

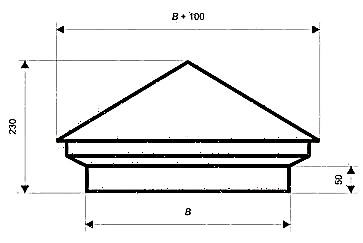

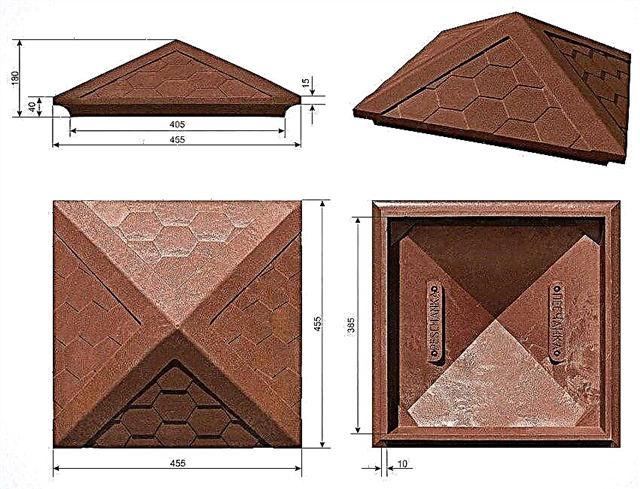

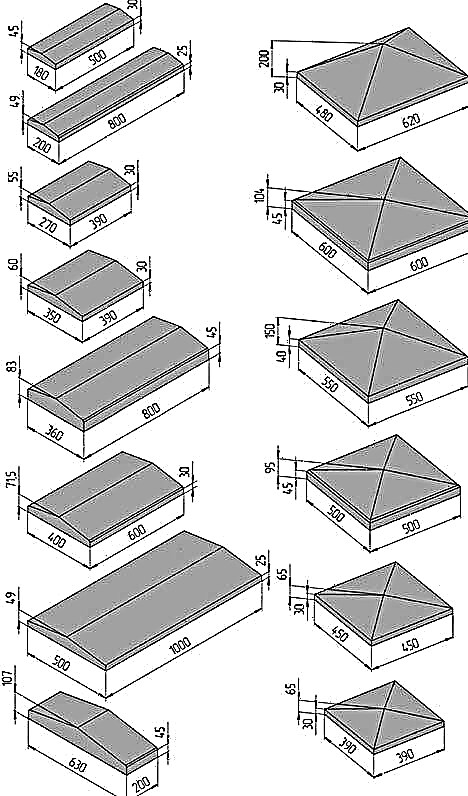

Popular sizes of products for brick fence posts: 38x38, 40x40, 40x60, 50x50, 60x60, 60x80, 70x70, 80x80 cm.

For greater protection of the supports and to give an original look, a special parapet can be installed on top around the entire perimeter of the fence.

Taking into account the material, caps for brick fence posts are of the following types:

- plastic

- fiberglass (glass ABS),

- metal (usually use tin, stainless steel, galvanized profiled sheet),

- ceramic

- wooden

- stone

- concrete.

Moreover, a large number of colors will delight any consumer. The most popular flowers are brown (RAL 8017), in tone of brick or tile, and green, under the bushes planted near the fence.

The surfaces of the protective covers for the fence are matte and glossy. It should be borne in mind that any cap on a brick pillar must match the overall composition of the installed fence.

To make metal caps on a brick support easier to mount, they are made hollow inside. This reduces their cost, and also allows you to operate in any weather conditions. Emptiness does not degrade the quality of the product and does not make hats brittle and unreliable.

The cost of the metal cover on the brick fence posts includes the cost of the production of the product and the price of the material itself.Therefore, stainless steel plugs for bricks made of stainless steel are inexpensive. In addition, they are easy to transport by simply storing them in the trunk of a car.

Lamps can be installed in the protective caps on the fence. This will help organize street lighting and decorate the fence.

Choosing a cap on a fence post, attention should be paid not only to aesthetic indicators, but also to the parameters of the future head. Before you buy a product, you must determine the size and material of manufacture.

If among a large selection of popular manufacturers (for example, Grandline) there is no suitable model, then you can make hats and a visor on a brick fence to order according to your own drawing.

The photo shows a beautiful cap for a brick support.

Features of choice

The design of the protective covers for the fence posts is very simple. On each there are only two main elements that fulfill their intended purpose:

- bottom part - fasteners, allowing to keep the cap on the chimney or brick support on the fence,

- the upper part plays a decorative and protective role.

To choose the protective cover for the fence supports made of bricks, you can use several simple rules. They will allow you to check the main structural details and fasteners, as well as determine the quality of the product:

- Look carefully at the protective tip from all sides. Determine its symmetry and proportions.

- Look at the eaves overhang - it should be tightly closed.

- Ask the store for tools to determine the correspondence of the actual angles of the product and those that are declared by the manufacturer.

- Before making an acquisition, you must once again make sure that the selected product is well combined with other elements of the fence and everything that is around.

- You should pay attention to the quality of the packaging material, this is important during transportation.

Compliance with the described paragraphs will allow you to choose and purchase caps on the pillar of the model that suits your own wishes.

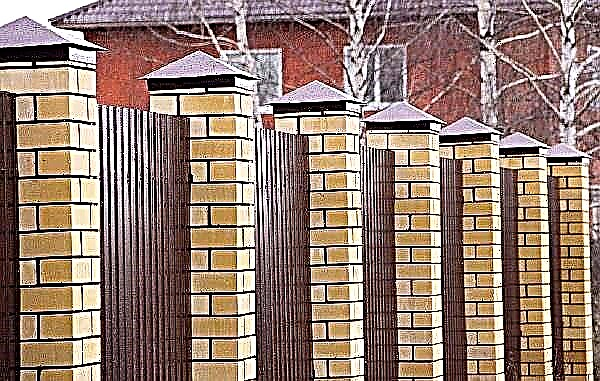

The photo shows a fence with pillars of brick in the country.

Do it yourself

To make protective covers on the fence post is not difficult. To do this, you can choose any material - plastic, plywood, wood, profiled sheet. The type and form will depend on the available workpieces, the availability of tools and skills in the work.

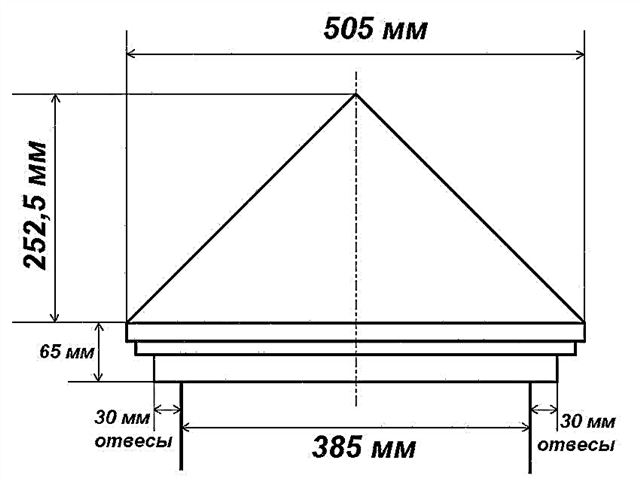

For example, you can describe the step-by-step instructions for the manufacture of protection in the form of a cone of roofing metal:

- Production is best started by creating a cardboard template on a 1: 1 scale. Why do I need to measure the length and width of the column, choose the height.

- Measurements are transferred to a cardboard. After this, you should get a drawing in which 4 triangles are the slope of the cap, as well as one deleted section during the bending of the cone.

- In case of complications with measurements of the exact size of the slopes, they can be selected empirically. With cardboard this task is done quickly.

- To create the edge of the fastener to the post, add 35–45 mm to the size of the cone.

- Transfer the drawing to a previously prepared blank. In visible areas, marking tools are used, and in those under the cardboard they are pierced with an awl.

- The material is cut with metal scissors or a grinder.

- The metal is bent with a rubber or wooden mallet on the channel, which is mounted in pliers. You can optionally put limiters. They will not allow workpiece shifts during operation.

- Rivet holes are made on the connecting sides of the protective cover.

- Assemble the product using a seat belt inserted inside the lid along the edge.

After correctly installing the side faces, you need to fix the elements with rivets. If they are missing, rivets can be chopped. Aluminum wire is best suited for this. So the design will be securely fixed on the fence posts.

The photo shows the caps on the brick racks of the fence.

Mounting Methods

Homeowners who build fences on their property need to know the following. Protection of brick fence posts should not begin when caps for supports were bought, but much earlier. You can temporarily close the end of the column with the help of a film, and use lace as fasteners.

Naturally, this does not look very attractive, but if you need to keep the fence post, then this option is quite suitable. It is only necessary to check the polyethylene for holes. Since even a small hole will allow water to penetrate inside, destroying this support.

To install a protective cover, you do not need to contact a specialist. Having a set of tools, you can do this job with your own hands. Any product has standard hardware. The only complication that may actually appear during operation is the installation of a header on a pole with built-in backlight.

In this case, a lot of time is spent on conducting electrical wiring in order to provide the lamps with power. Here it is worth asking for help from an experienced electrician. In this way, possible troubles and situations that are life-threatening can be avoided.

The installation of hoods and a canopy is the last stage of work to equip the fence.

You can do everything yourself. Even if protection on a fence made of concrete is chosen, it will not be difficult to lift it onto a pole. For fixing these heavy structures, special glue is used.

The photo shows a brick fence in the country.

Step by step installation instructions

The installation of the cap on the fence post is conditionally divided into a number of stages, observing which you can fix the element on the brick structure:

- The top of the support, where the protective cover will be located, must be cleaned of debris and then coated with a primer.

- If a cement composition or glue is used for fastening, it must be applied to the top of the fence post.

- A protective cover is placed on the treated surface and leveled with wedges. Use a level to ensure that the protective hat is level.

- All joints that appeared need to be wiped.

If the selected product does not provide for the installation of a visor, then the joint that appears between the column and the hood is additionally treated with a water-repellent.

It is necessary to allow the adhesive to dry. This takes several days, and during this period you should not have any impact on the fence. To begin the installation of a mailbox, decorative elements need after everything is dry.

Caps from a metal profile on fence supports can be fixed in several ways:

If glue is chosen, then the usual scheme should be followed. When using self-tapping screws, you need to accurately markup and get into the necessary holes to evenly fix the product from the profiled sheet on the post.

Special attention will require the installation of fixtures. You should take care of this beforehand, make all the required holes in the fence for cable management.

If you need to run an electric cable through the foundation, then diamond drilling is best to make holes.

The video clearly shows how to independently place the caps on a brick pillar.

The cost of caps

The range of products offered by manufacturers is huge. And sometimes it’s difficult to navigate. There are several models of protective covers for the fence that are popular today and are presented in the Leroy Merlin store from the Grand Line company:

- A galvanized cap with a polymer or sand coating with a layer of 5 mm, size 140 × 140 mm - 685 rubles.

- Round cap with a lamp, size 400x530 mm - 1390 rubles.

- A cap with a flat protective cap, size 400x400 mm - 490 rubles.

- The protective element "cabinet", the size of 450x450x50 mm - 560 rubles.

- Classic cap polymer sand terracotta, with a lamp, size 250x250 mm - 590 rubles.

As you can see, you can purchase Grand Line caps on the fence supports, having various material capabilities. The cost is significantly different depending on whether different decorative elements are on the protective covers. The width of the hoods of 400, 530 mm - the most common options. The most common column top is 50 mm.

Ceramic, clinker and forged caps can be classified as a separate group. They look pretty impressive, but very expensive.

If we consider as a whole, the cost of concrete products is much higher than metal intake caps. This is because they have more complicated production technology.

The photo shows a hat for a brick post fence.

Parapet Installation

The parapet is one of the obligatory elements of the arrangement of the fence. In addition to creating a complete image, it also plays a protective role in the design of the fence. But if at first caps made of cast concrete or clinker were chosen, then it is worth buying a concrete parapet. You should not mix different materials and install concrete caps on the supports for fencing with a parapet from a flexible profile sheet.

The main task of the intake parapet, like that of concrete or corrugated caps, is to protect the structure from the negative effects of moisture.

Just being horizontal, the surface is always exposed to sunlight and humidity. Over time, this leads to the appearance of cracks and deformation of the fence.

Investing money in the construction of a summer cottage, no homeowner would want all his efforts to be in vain and after a few years the fence received serious damage. Therefore, when calculating the budget, it is imperative to lay down such mandatory elements as caps and peaks for fence supports.

Caps on pillars for a fence of brick: why are they needed?

If you decide to buy a cap on a brick pillar, you need to understand what functions it should perform, what is required from this design and what is its purpose. Here are a few reasons to install caps on brick fence posts:

Caps on poles perform not only a decorative, but also a protective function

Do not neglect the meaning of these items. Moreover, this is not just a decorative element, but a necessary part of the fence. Fortunately, you can always choose an option that you can afford or make a cap yourself.

What are the caps on the fence poles

Even the simplest cap on the fence post can be described in several ways to get an idea about it. Just walking along the street, you can meet a wide variety of options, for example:

- simple cone-shaped structures

- hemispherical caps

- classic pyramidal designs

- caps, reminiscent of the shape of a pitched roof,

- designs decorated with various decorative elements, for example, forging or a ball.

In addition, there are models that mimic shingles or scales.

Decoration of the pommel with a decorative ball

Depending on the material from which they are made, caps can also be divided into:

- metal (usually use stainless steel, tin or galvanized steel),

- plastic

- concrete

- stone

- ceramic.

At the same time, the abundance of color solutions will delight even the most demanding customer. There are many color options, and it is necessary to choose an option that is most successfully combined with the color of the fence and the roof of the house. You can give preference to both a glossy and a matte cap. The main thing is that this element does not get out of the general composition and looks appropriate in it.

Well-chosen poles on top of the posts complement the overall composition of the site

In order to easily install metal caps on a brick fence, they are made hollow inside. This not only significantly reduces the price, but also allows you to effectively use them in any conditions. However, the inner void does not affect their quality, and does not make them more fragile and prone to damage.

The price of metal caps for brick poles includes both material costs and manufacturing costs. That is why caps made of stainless steel have such an affordable price. In addition, they are easy to transport by simply placing them in the car.

When choosing caps for brick fence posts, you need to focus not only on the aesthetic component, but also on the product parameters. To do this, before buying, you need to pay attention to the dimensions of the product, as well as what material the cap should be made of. If among the assortment of several fairly large manufacturers you cannot find a suitable option, then it is best to make an individual order.

Metal caps on poles can be either bought in a store or made to order

As a rule, individual manufacture of caps for the fence is carried out within 10-14 days from the moment of placing the order, having previously drawn up the drawing and carried out all the measurements necessary for the work.

What does the hood on a brick pillar consist of and how to be guided when choosing

The structure of the caps on the pillars can be called almost primitive. Each cap has only two components, each of which performs its intended purpose:

- the upper part performs two main functions at once: protective and decorative. Moreover, it can be of any shape and made of any material,

- the lower part is a mount that allows you to hold the structure on the post.

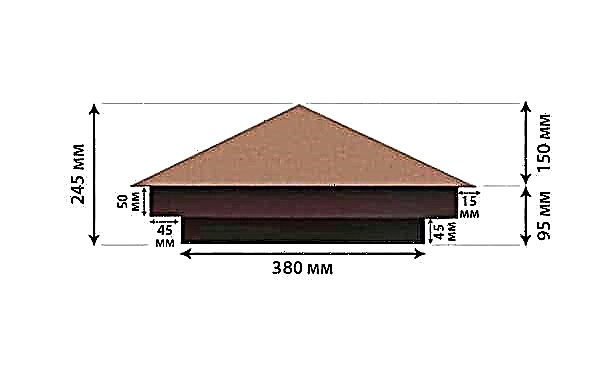

Dimensions of polymer-sand composite column top

In order not to make a mistake in the choice, making a purchase, you need to use a few simple rules. They will help you check all the most important elements and fixtures, and evaluate the quality of the goods offered:

The conformity of the product to all these points will help to choose and buy caps for the fence of exactly the model that suits your needs and wishes.

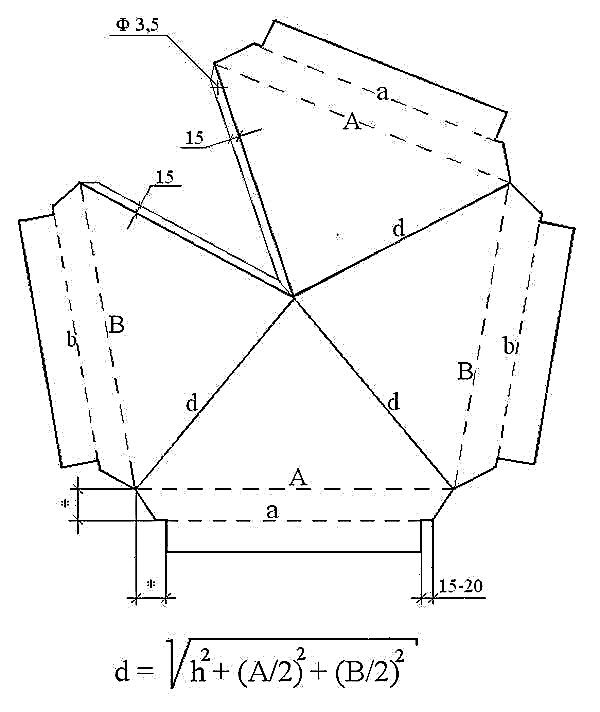

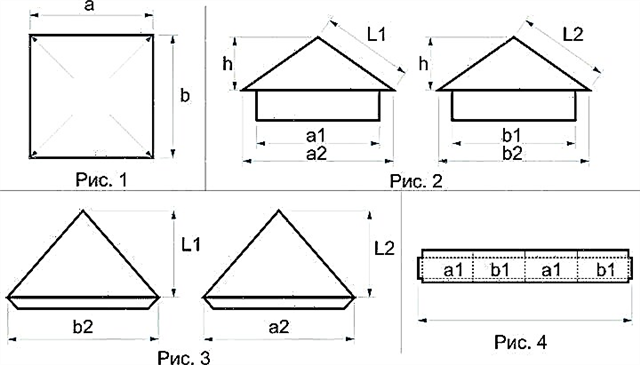

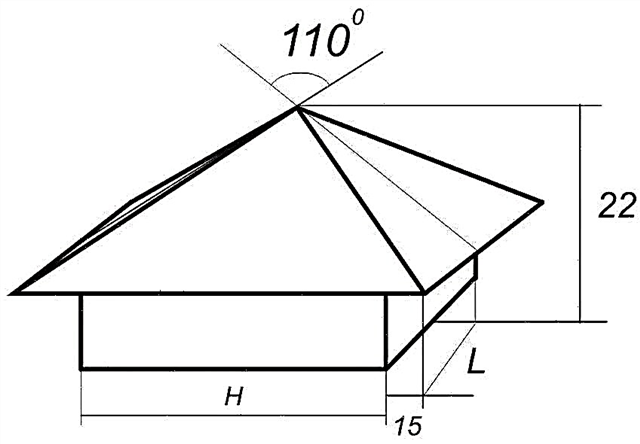

Dimensions for making the cap do-it-yourself, in cm. L and H - width and length of the fence post

Features of the installation of metal or concrete caps on brick pillars

The first thing you need to know for those involved in the construction of a fence around their home - the protection of the pillars does not begin at all from the moment you purchased the special caps, but much earlier. As a temporary measure, you can use a dense plastic film, as well as an ordinary rope or elastic band for fixing.

Obviously, this will look unattractive, but if we are talking about the safety of the structure, then we will have to sacrifice something for a while.The most important thing is to check the film for damage. After all, even a small hole will lead to the fact that moisture will get inside, exerting a destructive effect on the structure.

In order to carry out the installation of the hood, it is not necessary to turn to professionals for help. Possessing the usual set of tools, you can do it yourself. All models use standard mounts. The only difficulty that can actually arise during your work is the installation of the hood on the fence with a flashlight.

In this case, the wiring will take the most amount of time to provide power to the luminaires. It is better to turn to a professional electrician to avoid possible unpleasant consequences and situations that are dangerous to life and health.

For successful installation of the cap with a lamp, you must take care of wiring to the pole in advance

The installation of caps and skates is the final stage of installation work, so it should be taken with all responsibility. All this can be done independently, and even alone. If you purchased concrete caps on the fence, it will not be difficult for you to lift the 20-pound structure up. To fix such heavy products, special tile glue is used for outdoor applications.

Stage-by-stage installation of the hood for the fence

The installation of the cap on the fence can be divided into several stages, adhering to which you can reliably fix the element on the support:

- the top of the support column must be cleaned of dust and debris, and then primed,

- if you plan to use glue or cement mortar as a fastener, then it must be applied to the upper plane of the column,

- place the cap on the surface greased with glue and try to level it as much as possible with the help of wedges. Use a level to make sure everything is level,

- all seams that have arisen between the product and the support must be wiped,

Mounting dimensions for a metal four-sloped pommel

It is very important to let the glue harden on its own. This can take 2-3 days, and at this time it is better not to exert any influence on it. You can only start installing decorative elements when the cap is firmly fixed.

Metal caps on brick poles can be fixed in two ways:

- on a special adhesive,

- using self-tapping screws.

If you use an adhesive, then follow the classic pattern. In the case of the use of self-tapping screws, the main thing is to accurately measure and get into the prescribed place to evenly screw the structure to the post.

Particular attention is required to install lights on the hood. Care must be taken in advance by drilling all the necessary holes for cable routing. If you entrust this business to a professional, then save yourself from unnecessary trouble. But if you intend to do everything yourself, then it will not be superfluous to see a photo of the caps on the fence, as well as bringing electricity to them.

Caps made of metal on the fence posts: prices and specifications

The choice of models offered by manufacturers is very large. And to navigate in a huge assortment is not always easy. Consider some of the most popular models of caps that are on sale today.

| Name and country of origin | Specifications | Sizes, mm | price, rub. |

| Classic cap (Russia) | Made of polymer coated galvanized steel. It is presented in three different color schemes. | 400x400 | 653 |

| Cap with a ball (Russia) | The cap is equipped with a 250 mm ball-lamp, which serves as an additional light source and a decorative element. | 400x400 | 1350 |

| Cap with a flat cap (Russia) | The cap in the style of minimalism has a flat cover and a minimum number of additional elements. | 380x380 | 440 |

| Cap with a lamp (Russia) | A classic metal cap with a street lamp on top. | 400x400 | 1650 |

As can be seen from the table, you can buy caps on the brick pillars of the fence with different financial capabilities. The price of a cap for a brick pillar will differ significantly, depending on whether additional decorative elements are present on it.

Generally speaking, the prices of concrete caps for brick poles are significantly higher than for metal ones. This is due to the fact that they are more difficult to manufacture, and also require special care during transportation.

Concrete fence caps look simple and elegant

Despite the availability of fairly cheap models, many are trying to make a cap on a brick pillar with their own hands. This idea is not meaningless if you are sure that it will be easier for you to realize your plan on your own than to buy caps for fence posts.

Parapet for the fence: an additional element of the design of the fence

The parapet on the fence can be called a mandatory design element. In addition to creating a complete image, the parapet also has the function of protecting the design of the fence. But if you initially chose caps for concrete fence posts, then you need to purchase a concrete parapet for the fence. The big mistake is to mix different materials, and combine concrete caps on the fence posts with a metal parapet.

The main function of the parapet, as well as the metal or concrete caps on the brick fence posts, is to protect the material from moisture. The thing is that, located horizontally, the surface is constantly exposed to ultraviolet rays and moisture. Over time, these factors contribute to the formation of microcracks and the destruction of the fence.

If the fence is made of brick or stone, then it will be advisable to install parapets on it

Investing their financial resources in the arrangement of the adjacent territory, not a single owner wants the results of his efforts to be in vain, and after a couple of years the fence has received significant damage. Therefore, when distributing the budget, it is necessary to lay in it such important details as parapets for brick fences and caps.

Any business should be approached responsibly, especially if you have to observe the result of your choice daily. As you could see by looking at the table, as well as catalogs of manufacturers, the prices of caps for fence posts have very wide limits. Do not overly save on the purchase, but a high-quality and affordable option, despite its simplicity, can suit you the most.

Functions of Intake Caps

Depending on what features the fence has, pillar covers should have appropriate functions. A lot of fences are a frame with support poles on which the sections are fastened.

Pyramid Cap Example

Protection

Each pillar must have good protection against rain, wind, and snow affecting the state of the support. If moisture gets inside, destructive processes occur. The durability of the support is reduced, and this leads to a decrease in the life of the fence.

Most of all, protection is needed for steel pipes and brick pillars.

The plug on the pole closes the pipe and does not allow liquid to get inside the column, it also covers its outer surface. After all, if water gets inside, rust will quickly appear, the metal will soon become unusable. I must say that the paint layer does not save, it only slows down the corrosion process.

Schemes with sizes of different types of intake caps

Decorative function

Very often, cottage owners choose caps for their fencing, considering them as part of a beautiful setting or decoration. Of course, the appearance of the cover is very diverse, from which the price of the product can vary greatly.

On the lid, an invoice is sometimes made. Manufacturers supply caps with additional decorating details:

Original curls are set on forged caps, decorated with various patterns.

Fiberglass

This material differs from others in its unique properties:

- Low weight

- High strength

- Longevity

- Rainfall resistance

- Low price.

Today, caps made of such material are becoming very popular and in demand.

Fiberglass is a material from the group of dielectrics, so it became possible to install fluorescent lamps in the caps.

Caps made of ABS plastic are innovative. Such a material has the properties of fiberglass, it has a high decorative effect.

A selection of several options for plastic caps for fences

In conclusion, we can say that the plugs on the poles of any fence always complete the design of the fence, serving as a protection of the fence from a variety of natural influences, greatly extending its life.

Partial moisture caps

All varieties can be attributed to such caps, since the method of their installation and design features are very different, therefore it is impossible to clearly identify a particular variety, it increasingly depends on the method of their installation.

But still, if you want to get non-absolute, and at least partial protection, you should pay attention to the following parameters:

- The design should be seamless, and in case there are seams on its upper part, they must be airtight.

- It is desirable that the cap should not be easy to lay on the pillar, but should also be wrapped around it on all sides by small protrusions.

- There should be no holes or cracks.

- A concrete or metal product should somehow be fixed, and not just laid on top.

In the tops of concrete, frost-resistant cement of high grades is used, which makes it weather-resistant and not susceptible to temperature extremes.

Partial protection against moisture can protect concrete, brick and other columns from only a small amount of moisture, in any case, water can get from underneath, seep through the product itself, form inside the column itself due to leaking top cover over the column and the fence.

Tops with full protection

This kind of caps is possible only when using products such as various stone, concrete and metal. Using wooden caps, proper sealing cannot be obtained, since moisture will leak through the wood over time.

Caps-covers are divided into two main types: pillar caps and caps for fence sections, which gives full protection against moisture

As mentioned earlier, by and large the protection against moisture depends on the installation method, so using even absolutely non-permeable concrete products, there is a risk that moisture will pass through the slot between the column and the hood, if the installation is leaky. Concrete caps on poles are best installed on a special mixture of cement with sand or similar in properties.

Metal, it should be installed on sealants, or silicone glue, they will create an airtight seam that will restrain any moisture. Stone caps are installed in the same way as concrete ones for mortar.

Decorative items

Caps on the fence with a decorative or universal purpose have the most diverse and beautiful form. Very often, peaks for fences and poles, various small statues, forging, etc. are used as decoration. The most affordable are metal and concrete decorative products, both in price and in prevalence in stores.

Very often, concrete caps are complemented by a vase, on top of which you can pour earth and plant flowers. Of course, such plants require care, and it will be necessary to work with them using a ladder and a stepladder, which is not always convenient.

Thanks to the development of technologies related to lighting, it is now possible to use any lights on the street, without fear that they will be damaged or moisture, will get on the elements connected to the electrical network. Decorative caps with built-in lights are no exception.

Use of caps as an additional light source

This design decision is very beautiful and unique, you can illuminate the entire area of your yard around the perimeter and create an unusual effect. In addition, passers-by that will take place at night near your yard will thank you for the partial coverage of their path.

If you want to use LED lamps, you can decorate the perimeter with a variety of colors of light, and by connecting the entire circuit to a special controller and control system, arrange unique lighting, the play of light and other effects.

Installation and maintenance

In order for the installation to be carried out as efficiently as possible, pre-arrange a flat and smooth surface for installation. The fewer roughnesses and large irregularities, the better the cap can fit on the surface. As previously mentioned, concrete caps are fixed using a cement mixture, in rare cases, metal plates are removed from them, with which they are fixed.

Metal caps are fixed to the lower ledges, directly into the pillar itself, using self-tapping screws or dowels. Wooden ones are directly screwed to a pole or laid on special glue or resin.

In order for the lid to serve more, it must be constantly restored if it is required to tint and clean from accumulated debris. If debris is constantly lying on the decorations and simply on the surface, the risk that corrosion and shedding of the material appears faster increases significantly.

Metal covers should be regularly tinted, if cracks appear on concrete, they should be repaired with a mortar and also painted in the color you need, thereby refreshing the old paint and covering the restoration site.