To give private or industrial territory grooming and respectability allows a competently designed entrance group. Today, as many years ago, the gates of various configurations continue to guard interests and security. Another thing is that now there are much more types of locking structures that can satisfy any consumer needs. And one of the most common privacy options is electric sliding gates.

Benefits

- Compactness

- Silent

- Convenience,

- Distance

- Reliability,

- Durability,

- Versatility

- Security,

- Quality

- Presentability

The advantages of sliding gates boast of breadth and diversity. The main advantage of the design is compactness and noiselessness during operation. Convenience and ease of use is also not in last place for a modern person. In this parameter sliding gates far surpass any other types of devices. Budget equipment involves a manual control method. The optimal installation kit additionally includes a drive that allows the opening / closing of the wings automatically by pressing a button on a special panel or by sending a command remotely from the remote control.

In addition to the benefits directly related to the operation process, sliding gates have a number of important technical characteristics. The reliability of the installation and the quality of the accessories ensure a high level of confidentiality and guarantee the safety of property located in a fenced area.

Durable material coated with anti-corrosion compounds can withstand various influences, including the effects of adverse weather conditions. At the same time, sliding gates throughout the entire service life do not lose a presentable appearance, and the operational period itself is durable.

Finally, the universality and safety of the design should be added to the treasury of positive qualities. Sliding gates with equal success can be installed on the site in front of a private house or at the entrance to the courtyard of a large industrial enterprise. They move easily and are not capable of causing damage to the vehicle while driving. Add here a large selection of designs and a wide range of colors. And picking up the original fittings, you can create a truly memorable and unusual design of the entrance group.

We make measurements

Mass and overall characteristics - one of the most important factors of the future gate.

Regarding the indicators of the length, width, height and weight of future sliding gates, it is easy to choose the necessary components, accessories and automatic power for reliable operation of the structure.

Weight is easy to calculate, knowing the weight of the sheathing material. The power of the electric drive, the thickness of the console and the profile depend on the mass of the web.

The length depends on the size of the car and the maneuver during the race. The standard length is 4.5-5 meters. The length of the entire sash is 1.5 times the length of the canvas.

Foundation arrangement

Before you start pouring the foundation on electric sliding gates, you need to make a drawing with all the elements and design parameters.

The foundation should correspond in terms of:

- Length. The support should be at least half shorter than the length of the opening,

- Width. Reliable width 60-70 cm.

- In depth. At least 1.5 meters.

- Location. The foundation is located on the side in which the canvas will move.

We put roller bearings

Can be made of metal or polymers. The latter will not tolerate the harsh weather conditions in Russia and are intended more for internal gates (at enterprises). The ball mechanism is better to choose with metal-rubber gaskets, again based on operating conditions.

The rollers must be protected from corrosion by a protective layer (the roller will be without dark spots). For the operation of electrically operated sliding gates, it is important to fix the rollers with a gap of 1-2 mm from the guide rail.

Toothed rack mounting

- A gear rack should be placed in the center of the gear (it is important that the wings are open). There must be space for mounting limit switches.

- Weld the fasteners of the rail to the profile pipe of the outer frame.

- Weld the second segment so that at the junction the order of the teeth is not lost.

- Make a clearance by unscrewing the bolts on the rail and exposing it so that the rail is in contact with the gear and emits a characteristic clatter.

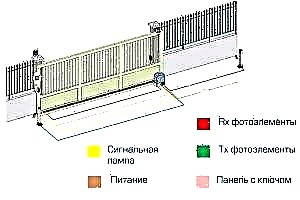

Installing Security Photocells

Photocells are one of the most important gate components, because it is responsible for security.

Mount strictly opposite each other to receive a clear light signal. After all, when the signal is interrupted, the gates begin to open so as not to harm a person, a car or an animal passing through an opening. Photocells are mounted on poles:

- Bearing

- With a bottom catcher

- Separate from profile specifically for photocells.

Signal lamp connection

An important element of security, fastened with screws from the outside to alert about leaving vehicles.

Retractable canvases save space both outside and inside the courtyard; when entering a vehicle, you don’t have to worry about the dimensions of the car and the gate leaves. Fully automated save time and are easy to maintain, stand idle for a long time, reliably protecting their owner.

Design Features of Sliding Gates

The design of the gate is simple and has the following the elements:

- shield,

- base frame

- guides and rollers,

- electric drive.

home feature sliding (sliding) gates is enclosed in the name itself. Rollback to the side, thanks to a simple design, has existed for a long time, but recently this type of gate has become increasingly popular.

Sliding gates are presented in the form of a rectangular frame sheathed by sandwich panels, the profile of which consists of aluminum or galvanized steel. Pre-profile is treated with a special protective agent that is resistant to corrosion.

Power frame - This is a supporting structure, which is made of metal, and then concreted.

Guides are installed in the upper part of the frame, and catchers (lower and upper) are installed on the opposite side.

Videos located at the same distance and in two places of the structure.

The movement mechanism is represented by an electric drive, which can be controlled using a stationary button or remote control. Since the mechanism is automatic, it greatly facilitates the opening and closing of the gate to the driver in bad weather.

There are sliding gates of three species:

- hanging

- cantilever

- rail.

Outboard gates are most often used in industrial enterprises. They are huge in size, and installing a gate is very expensive. But it’s impossible to break into such a gate. Negative factors do not affect the appearance of the material.

Outboard gates are most often used in industrial enterprises. They are huge in size, and installing a gate is very expensive. But it’s impossible to break into such a gate. Negative factors do not affect the appearance of the material.

Cantilever the design is considered the best both in the domestic and in the world market. The device is silent, you do not need a ready-made opening, simple installation. Only this model has many details: frame, rollers, guide rails, cantilever blocks, supporting bracket.

Rail mechanical gates do not require much space, are very convenient and easy to operate. The canvas on wheels is mounted on a rail, which is laid on the ground. Mechanical influences do not affect the appearance.

DIY sliding door installation

To install the sliding gate you will need the following tools: shovel, welding machine, scrap, tape measure, level, hammer, drill with drill bits for metal and grinder.

To install the sliding gate you will need the following tools: shovel, welding machine, scrap, tape measure, level, hammer, drill with drill bits for metal and grinder.

Door leaf set along the fence. The place of haulage should be determined in advance, this will help you design drawing. On the construction market or in specialized stores for construction, you can buy all the necessary materials. After the purchase, you can proceed with the installation, which consists of several stages.

- Manufacture and installation of pillars. You can use concrete poles, a metal pipe or wooden beams. For strength, they should be concreted. Depth should exceed 1 meter.

- Foundation position along the fence and concrete. For this purpose, we dig a trench with a depth of about 1 meter, a width of no more than 0.5 meters. The length should be half the size of the opening.

- Manufacture metal parts of the gate. A metal channel with a width of about 15−20 cm is required. Its length should be equal to the length of the foundation. Then, metal legs with a diameter of 13 mm are welded to the channel. After that, the metal part is laid in the trench with the legs down and concreted. Wait a week before the concrete has completely dried. During this time, you can make sliding gates.

- Welding and coloring of the shield. First you need to remove the marks of corrosion and oil stains from the metal pipes and rail with a grinder, and then degrease with gasoline or other special means. Then an anti-corrosion primer is applied and left for a while until completely dry. After that, cook the frame. To do this, a six-meter guide rail is taken, which is cut down, and a profile pipe of 60 × 30 × 2 mm is welded to it.

- Then vertical pipes are installed and welded onto this pipe. racksthe same size. They must first be measured with a square. The outer gate frame is ready. The final touch is to weld an inner pipe 40 × 20 × 2 in size. Grind the seams with a grinder and apply a primer to the finished canvas.

- The canvas itself can to stain a brush or a special spray gun (if you know how to use it). When the paint has dried, flashing should be done with wood, metal sheet or plastic.

- Mount the mechanism. We install the roller system on the channel. It is fixed with a side part and a guide rail is placed on the roller trolleys. Then the canvas needs to be set along the fence and welded. Gate catchers and movable rollers are fixed on supporting poles. You can fix it with welding, dowels or clamps.

The gate is controlled by automatics. If you do it yourself, it will cost much cheaper than the acquired automation. This is a rather painstaking job that requires a lot of effort. You need to purchase an electric motor, it must be located on a special rack.

Homemade sliding gates will cost you about 400-500 cu, depending on the material and quality of components.

Possible errors when installing sliding gates

If you install the gate yourself, you can make some mistakes. The most common mistakes when installing sliding gates:

If you install the gate yourself, you can make some mistakes. The most common mistakes when installing sliding gates:

- Improper ground preparation.

- Poorly or improperly fixed components.

- Incorrectly selected gate weight for the support beam. For this reason, the gate may sag.

- If the gate started to creak, this indicates that there is sand in the bearings that needs to be removed, or during installation the distance between the bearings was measured less than normal.

- If there are smudges at the welding sites, this indicates the wrong technology for painting the web. The surface should be degreased, cleaned and primed, only then proceed to painting.

- So that the columns do not skew one side and do not swell, you should take into account the depth of freezing of the soil and the mass of the foundation. He must be several times more the load itself.

Installation of movable works is simple, therefore, if you follow all the recommendations and rules, you can easily install them yourself.

Advantages of sliding gates

- Sliding gates are made according to individual measurements,

- Products save space (compared to swing systems), gates open to the side along the fence,

- There is no need to clear the area in front of the gate from snow, the product is not affected by wind loads,

- Functionality of products: restriction of entry of vehicles into the territory, protection of a private house,

- The gates open easily, work for a long time, the reliability of the design is certified,

- The width of the hinged gate can reach twelve meters, that is, products can close large-sized openings while fully fulfilling the functions assigned to them.

Sliding gates can have a different design. Interesting solutions can be obtained through the use of corrugated board, polycarbonate and sandwich panels. There are also forging design options.

1. Professional flooring refers to the budget option itself, so it is the most common. Its advantage is its simple installation and resistance to corrosion, which indicates the durability of the product as a whole. The canvas from this material is covered with polymer paint (it can be combined with the exterior of the house, the tone of the garden, and so on).

2. Polycarbonate goes well with forged elements in the design. The stiffeners of the material originally refract the light, emphasizing the delicacy of the pattern on the door leaf.

3. Sliding gates are popular, in the frame of which a sandwich panel is installed (as in sectional gates). Sandwich panel filling for sliding gates matches the architecture of any style. As a heater, high-density polyurethane is used.

Types of sliding gates

The basis of the gate is a reliable and high-quality rollback construction and a stable base.

Electric sliding doors are divided into two main types:

- Cantilever Gate

- Gate on the support roller.

1.Cantilever gate are in a suspended state, move along special blocks that are installed on the embedded profile. Elements are at a certain distance from each other. The lower part of the frame is mounted on a steel profile that creates a counterweight. This ensures smooth rolling of the gate along the console rails.

The guide profile is made of heavy-duty steel, so the product is held firmly in place. The length of the standard profile is six meters.

2.Sliding gates move along the guide profile according to the principle of tram rails. The design lacks a counterweight system for the gate. Special bearings protect the product from rolling, provide it with ease of control and smooth movement.

The product is made of a profile pipe, which provides it with rigidity and resistance to any mechanical stress. The system does not deform for a long period of operation.

Both systems of sliding gates can work on the manual and automatic drive. The products are equipped with a security system that stops the movement of the gate when an obstacle or any object is detected.

Electric sliding gates

The term "sliding gates" comes from the principle of their work. The basic configuration of the sliding door device with a drive is:

- Canvas - counterweight and aperture,

- Supports or roller carriages support the canvas, so the gates do not touch the ground during movement, they slide smoothly along the opening,

- The end roller is designed to unload the support in the closed position of the gate,

- Low and high level catchers are auxiliary safety locks,

- The guide axis is a beam with a profile along which the web is moved,

- Latch

- An automatic system for gates - a drive, a warning light, photocells, a control panel, etc.

Automation in sliding gates

Separately, you should stand on the electric drive for the gate. The electric motor of the system is protected from overheating by a special thermostat (the threshold reaches 150 degrees). To unlock the system is an aluminum handle with a personal key. In the event of a power failure, it will unlock the system and manually open the gate.

The automatic system for sliding gates is selected with particular care. The smallest construction details are taken into account here. It is important to understand that the system is directly proportional to unauthorized entry into a certain territory.

The structural elements are made of bronze and steel. These materials several times reduce heating, friction and wear of parts and the entire system as a whole. Control over the movement of the gate is carried out by an incremental encoder. It has the role of providing a return stroke or stopping if an obstacle is detected

Sliding gates with electric drives provide their owners with a lot of advantages, simplify their maintenance and operation. According to individual preferences for the systems, you can pick up the components in the appropriate style. Products can be purchased at an affordable cost.