Today is the era of progress. He touched all spheres of life. Every day, the latest and most modern building materials appear. One of them is a new polymer-based putty. This mixture is of high quality. What are the advantages of polymer putty in comparison with traditional building materials?

What is this modern material?

Before talking about what these technological mixtures are, it is worth figuring out the goals of the putty. In ordinary houses, the walls are in very poor condition, although they may have an excellent design. Often the wall does not meet the requirements and building codes. And what is the most important parameter for the walls? Evenness. It is by this characteristic that the quality of the walls is determined. Even if it seems that evenness is perfect, it is actually an illusion. Naturally, there are exceptions, but it never hurts to finish the wall with putty.

Polymer putty is a chemical novelty in the construction industry. Such mixtures in a short period of time have become very popular because of their characteristics. These building compounds are suitable for both indoor and outdoor use. They contain unique binding polymers.

Purpose and use

The purpose of any putty is to level the surface of the walls and ceiling. The compositions are divided into the following types:

- leveling

- finish,

- universal

- special.

The leveling mortar is used when a rough finish is necessary. Such polymer putties for walls are applied in a dense layer in order to eliminate defects. They should keep their shape well, not slide on the surface, not shrink, and after hardening form a strong durable coating.

Finishing polymer putty eliminates minor flaws and hides microcracks, forming an even and smooth plane. It is used as the final stage of leveling the wall surface and is applied over the rough structure.

Universal mortar can be used both instead of a white finishing polymer putty, and as a starting composition. Of course, in some respects, putty will be inferior to products with a specific specialization (for example, a thinner layer, longer drying time, less ductility), but it is quite within her power to hide some defects.

Special tools will include additional components that give the mixture the specific properties necessary to solve certain problems. The manufacturer places the detailed information on the properties of such a product on the package.

In addition, putty mixtures can be conditionally divided according to purpose:

- For internal work,

- For outdoor work,

- Universal.

Attention! Information on the purpose of the material, layer thickness, drying time and type of substrate can be easily found in the instruction manual.

Consumption per 1 m2

In order to calculate the consumption of polymer putty it is necessary to measure the perimeter of the room and the height of the walls.

Calculation of the product per 1 m 2 is carried out according to the formula:

- putty consumption rate per 1 square meter is multiplied by the thickness of the flaws of the plane,

- the length of all the walls in the room

- the length of the wall above the doorway is multiplied by the height in the same section, the sum of the height of the walls is added to this indicator,

- the result of the first calculation is added to the sum of the lengths of all walls, this result is multiplied by the obtained number of the third action.

Advantages and disadvantages

The use of polymer putty for internal work has a number of advantages due to which the composition has surpassed gypsum mixtures in popularity.

The main advantages of the product is the combination of plasticity and elasticity, due to these characteristics, the solution can be applied with a light layer. In addition, the unsurpassed quality of the mixture allows you to work with the material on a rough plane.

Taking into account the properties of polymer putty, we can conclude that it is easy to use and does not require extensive experience, because the possibility of applying the mass in a thin layer greatly facilitates the work.

The composition of the product includes plasticizing and modifying substances, ensuring excellent adhesion to the working surface. It is also noteworthy that a well-dried polymer putty is not characterized by peeling, swelling and bubble formation.

Discussing the advantages of modern puttying mass one cannot but mention the absence of shrinkage. This quality indicates the absence of the possibility of cracking and discharge of the freshly applied solution. In addition, the high elasticity of the composition protects the integrity of the treated surface, even in conditions of natural subsidence of the building.

For any type of polymer coating, water-repellent properties are characteristic, which allows the use of putty in wet rooms. The moisture resistance effect is provided by a specific barrier film.

The formation of a barrier allows you to withstand the temperature load. The composition is not subject to spontaneous combustion or melting when raising the thermometer. It is not toxic and does not emit substances harmful to humans.

Polymer putty is vapor permeable, which is the reason for the reduced risk of the formation of fungal colonies. This feature is very relevant for rooms with high humidity.

Among other things, the finishing, starting and universal putty gives the surface additional sound and heat insulation properties, which creates a comfortable microclimate in the room.

The disadvantages of the polymer mixture include the high cost of the product. At the same time, this particular composition is a guarantee of durability and reliability.

Types and characteristics of polymer putties

Polymer putty is a general definition that is used in relation to several varieties of compositions made on the basis of polymers. It is customary to distinguish three types of putty, which differ in the main polymer component:

- Polymer cement putty. The product is used as a leveling agent for cement-lime, cement-sand, brick and concrete planes. The plastic mass can be applied with a layer of up to 20 mm, which allows the use of polymer-cement putty as a starting coating,

- Latex. Styrene is considered the main component, it is also often called acrylic latex. Using the mixture, a neat and even finish is obtained. The scope of the solution is very extensive. The composition can be used both on wood, on brick, concrete or GKL. There are two forms of latex putty production: dry and finished.

- Acrylic polymer. The main component is acrylic. The product is considered universal and can be divided into the following subclauses:

- Starting putty. It is used to eliminate large flaws on the surface: cracks and potholes,

- Finishing putty. Finishes the finish and gives the plane perfect smoothness. It is applied under the wallpaper or coloring composition,

- Universal putty. It includes the properties of the starting and finishing mixes.

Application tips and tricks

When working with polymer putty, professionals recommend sticking to the following recommendations:

- To apply structure only on previously prepared surface cleared of an old covering, grease, dust and other pollution. Before using polymer putty, the work plane should be treated with mineral soil.

- To knead the solution, dry powder must be poured into a container with liquid and thoroughly mix the contents manually or using an electric drill equipped with a mixer nozzle. After, the mixture should be left for 10 minutes and mixed again.

- The material is applied to the wall surface using a spatula or kleme, with a layer no thicker than 0.3 cm. In this case, the action algorithm should be as follows. With the help of a trowel, a certain amount of the composition is collected, which is transferred to the spatula. Next, the tool with the finished solution is applied to the working surface at an acute angle. The mass is not in a dense layer distributed on the base.

- When the putty mixture has dried, its surface is leveled with sandpaper. To do this, make movements in a circle without excessive pressure. If one layer of the mixture is not enough, a second one can be applied no earlier than 4 hours after the previous one dries.

Important! Choosing between polymer or gypsum putty, the consumer must take into account that compositions based on polymers can solve a wide range of problems. These mixtures are suitable for various types of rooms and have good technical characteristics, while the scope of application of gypsum putty is rather modest.

Overview of popular manufacturers

Faced with the problem of choosing a polymer putty, professionals recommend giving preference to goods of well-known brands with an impeccable reputation. Such mixtures are well diluted, form a high-quality coating and do not deteriorate over time.

It is worth paying attention to the following products:

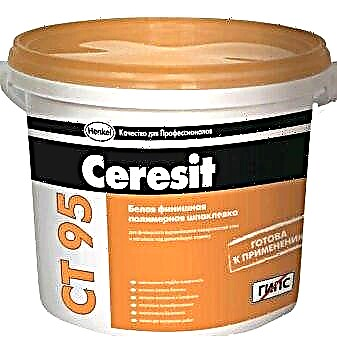

- on products of the Ceresit trademark, which offers a wide selection of putty mixtures,

- on the compositions "Prospectors" and "Hercules", suitable for rooms with high humidity,

- on latex putty "Tex", which has high elasticity and an extensive range of colors,

- on the EC mixture, which perfectly mask flaws on various surfaces,

- with Knauf funds, presented in a large assortment and forming an ideally smooth plane,

- on Vetonit putty, which is characterized by an ideal ratio of price and quality.

- on the safe Scanmix product for outdoor use.

Acrylic Putties

This material is distinguished by its unique properties. Acrylic putties are successfully used not only in various wet rooms, but also for facade work. This material calmly tolerates atmospheric phenomena, temperature extremes, humidity and the like. And besides this, it passes air well, which will not allow the formation of fungus or mold on the surface treated with acrylic polymer putty. This material is not as plastic as latex, and more capricious in work. To maintain the working consistency, this putty must be regularly mixed.

Latex putties

Materials made on the basis of polymer rubber resin. They have excellent vapor permeability and strength properties. However, in conditions of high humidity showed themselves not in the best way. Most often, this putty is used to perform interior decoration of residential premises or offices. It is flexible and easy to use - for this both professional builders and amateurs love it.

Polycement

An interesting and rather new finishing material based on polymer (that is, synthetic) cement. Polycement can safely be called a universal finish, as it is equally well suited for both indoor and outdoor use, can be used in rooms with high humidity and other aggressive conditions.

Polycement is convenient in that it can be used to repair deep cracks or grooves - it can be applied up to 30 centimeters thick - and this is a very significant layer, with which even very curved surfaces can be leveled. If an even thicker leveling layer is required, then polycement can be used with a special reinforcing mesh and then it can be applied in two or more layers.

Where are polymer putties used?

First you need to decide what kind of product is needed in each case. Putties are for leveling, finishing and universal. Also, special putty mixtures are produced on the basis of polymers - for wood, concrete and the like.

Leveling polymer putties are not cheap - most often the cost increases due to the required layer thickness. But, despite the price, they are actively bought, due to the excellent physical and mechanical properties of the polymers.

Polymer-based finishing coatings are used to seal microscopic cracks, crushed stones and other imperfections. In addition to this function, the finishing putty gives the surfaces an ideal appearance - makes them perfectly even and smooth. The final coating is applied with a very thin layer, the polymer component allows you to get a strong layer even with a putty thickness of several tens of millimeters! This can significantly reduce material costs.

Polymer putties are perfect for cement, concrete, gypsum substrates, and can also be used on top of previously plastered surfaces to give them smoothness.

How to use polymer putty?

In many respects, the quality and durability of the finishing layer depends on the correct application and adherence to the technology in the work. Therefore, as with any building material, when working with polymer putties, it is important to do everything correctly and consistently:

1) Surface preparation. The base on which the putty will be applied must be properly prepared: thoroughly clean from dirt, dust, and also pay attention to grease stains - if they are, then be sure to degrease with an alcohol solution.

2) Primer. Prior to puttying, cleaned surfaces must be opened with a mineral-based primer. This must be done carefully, without missing a single centimeter. It is possible after the first layer has completely dried - to apply the second, so the base will be more reliably primed.

3) Mixing of dry putty mortar. If a dry putty mixture is used, then it must be independently brought to the desired consistency. To do this, following the recommendations indicated on the package, it is necessary to mix dry powder with clean water at room temperature. First, mix well with a spatula or trowel, and then, when the mixture thickens, it is best to use a special construction nozzle - the “mixer”.

After stirring, leave the mixture alone for ten to fifteen minutes, and then stir again, following the structure of the finished solution. If it is liquid, add a little powder, if, on the contrary, it is thick, then add water.

4) Application of polymer putty on the surface. It is most convenient to apply polymer putty most of all with a medium-sized trowel or trowel. Correct is considered the technology of using two spatulas. Small a small amount of material is applied to the edge of the wide one, and then, keeping the putty knife at an acute angle to the surface, the putty is transferred to the base. The thickness of the layer should be no more than 3 millimeters - otherwise, the putty may unevenly dry, deform, and the like.

During operation, it is necessary to carefully monitor the uniformity of the layer, trying to make it minimal and even. The main polymerization of the material occurs within 4 to 5 hours after application. This is subject to ambient temperature.

5) Grout surface. Therefore, after this time, it is advisable to clean the putty layer with construction sandpaper with fine dispersion. You can also use a special grater for grouting. They are rubbed with uniform circular movements, trying to observe the same degree of pressure on the tool. However, it is not worth it to be diligent with pressing - the grout should be light and not damage the putty layer.

If further finishing is planned in the form of painting or partial decorative finishing, that is, one in which the finishing putty should create a perfectly smooth surface, then a second layer of polymer putty is desirable. This must be done approximately four hours after the first - during this time it should dry out and it will be possible to clean it, and then apply the material again.

Actually, that’s all the subtleties of working with polymer mixtures - there is nothing particularly complicated or impossible for the most ordinary user, who has never even before been involved in repair or finishing work.

Polymer putty grades

Currently, a large number of polymer finishing materials are presented on the construction market. In particular, the range of polymer putties is constantly updated and pleases with new products. At the same time, there are materials that have already established themselves as the most successful and enjoy increased attention from buyers. Here is a small list of the most popular polymer putties:

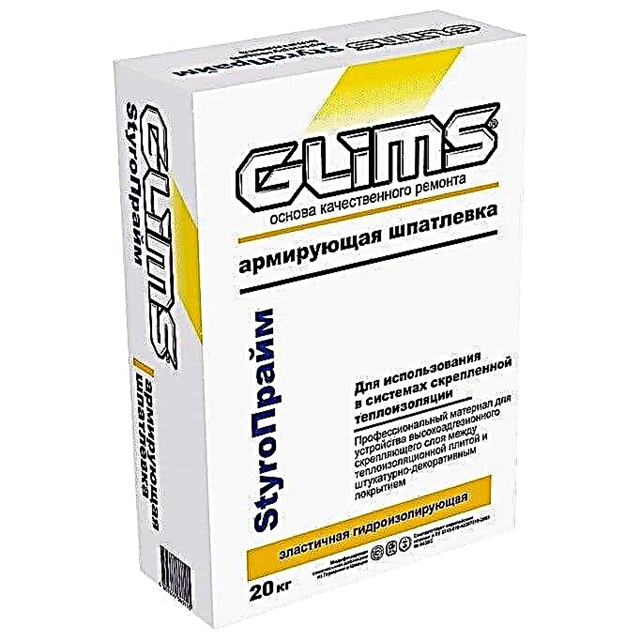

GLIMS Styro Prime

Universal starter putty. It is convenient in that it can be used for various operating conditions: moisture, temperature changes, plus frost resistance. Such properties allow it to be used both indoors and for facade work. Suitable for bathrooms, swimming pools, insulation works and the like.

GLIMS Styro Prime - has all the necessary safety certificates for health and can be used in residential premises. In operation, it is convenient, quickly sets and has an elastic consistency.

Sheetrock SuperFinish

The American brand, which now has its own production in Russia. Sheetrock SuperFinish is a finishing polymer putty, which has firmly established itself with perfect adhesion and an absolute absence of shrinkage. This material has high strength, excellent plastic properties and fast adhesion - it dries in five hours.

Sheetrock SuperFinish is an excellent material for creating a perfectly smooth and smooth surface, after which it is possible to paint, wallpaper or any other kind of finish.

White house

Universal polymer putty based on acrylic copolymer. It is made in Russia and has a high sales rating. It is suitable for exterior and interior decoration, it is resistant to atmospheric phenomena, it is also convenient because it can be applied with a rather thick layer - up to seven millimeters. After drying, White House gives a snow-white, perfectly smooth layer suitable for any type of subsequent finish.

Polymer putties are currently materials that are constantly improving in composition and properties. Their production began not so long ago, but due to their unique properties, polymers are actively developing and are firmly in the ranks of popular finishing materials. Yes, their cost often exceeds the cost of traditional putties, however, the operational properties of polymer putty mixtures are much higher. If we talk about reliable high-quality coating for many years, then it is polymer putty - this is exactly what can provide it.

Gypsum putty

To prepare a gypsum-based working mixture, use:

- gypsum (in some cases alabaster),

- water soluble polymers

- mineral fillers.

Due to the use of gypsum, marble flour and quartz white sand, the mixture has a white color, in some cases light yellowing is allowed.

Depending on the size of the fractions, putty is divided into two types:

- Homepage. Its purpose is to hide small surface defects, remove cracks and chips of the base, therefore, large fractions of bulk materials are used in the composition of the starting mixture. It serves as the basis for the final leveling layer.

- Home. To obtain a flat and smooth surface, only fine fractions of bulk materials and special plasticizers are added to this putty. Application - final finishing. On the finished surface, you can glue wallpaper or apply paint.

Scope of gypsum putty:

- elimination of minor defects (chips, cracks),

- masking of joints of sheet material,

- alignment of the bases for subsequent gluing or painting,

- stucco molding on the ceiling,

- decoration of arches, cornices and columns.

Manufacturers most often produce this type of putty in bags of 20-25 kg. For subsequent dilution of the material with water to the desired consistency, follow the instructions printed on the package. In some cases, it is possible to purchase a ready-made pasty mixture in a plastic container.

Given the hygroscopicity of the basic material, the use of this type of putty is possible only in rooms with normal humidity, and they will not be suitable for a toilet, bathroom or kitchen. The finished surface “breathes”, letting in fumes.

Plaster putties can be applied on the following bases:

Features

Polymer putty is a chemical novelty in the construction industry. She appeared on the market recently, but managed to take an active position: this material has high quality characteristics. Being preparatory to the finishing material, it allows you to even out the curvature of the walls, rid it of cracks and seal joints.

Outwardly, it is a paste-like mass, through which defects in the foundation are corrected before cladding, which means that it is an element of the adjustment of the foundation and affects the final result of the repair of treated surfaces.

In addition to the polymer, the components of the polymer putty are a hardener and special additives necessary for surface treatment of a particular type. Therefore, the purpose of this putty is different, and you should buy it, strictly focusing on the labeling. For example, a variety for surfaces from solid wood contains small dust-like sawdust. In this case, the composition may have a shade similar to the tone of the treated surface.

The composition of this putty contains latex and acrylic, which are responsible for the connection of all components. It is used pointwise, applied exclusively to problem areas of the base: cracks, pits, scratches and minor chips. The use of large areas is impractical: the composition is not designed for significant loads, after solidification it will withstand careful handling.

The scope of this raw material is extensive, however, it can be used only for its intended purpose with the addition of the desired percentage of hardener.

Polymer putty is sold in the form of a dry powder composition and finished raw materials. In the first case, it needs to add water in the proportions indicated by the manufacturer on the packaging of the goods. In the second type of release, the material is ready for preparatory work. These are pasty mixtures of different volumes in a sealed container. In the process of working with the material, it can become thicker.

Filling acrylic

This is one of the widespread types of polymer putty mixtures. The product is very versatile and can be used for a wide variety of jobs. Often, these compounds are used for interior decoration, but it is also an excellent choice for any outdoor work.

One of the characteristics is the perfect alignment of the wall. The mixture can even be used as a finish. If it is necessary to level the surface of the wall, but it is not clear what to use, then the acrylic putty is the universal tool that is sure to fit.

Polymer putty

The following materials are used to prepare the working mixture based on polymers:

- as the main component - acrylic, polymer cement or latex,

- fine-grained mineral fillers.

The difference between polymer putty and gypsum putty lies in the chemical method of manufacturing dry matter.

The following surfaces can serve as a basis for applying this material:

For metal surfaces this type of putty is not applicable.

Polymeric materials allow you to get a sturdy surface with perfectly white color, which is suitable for wallpapering and painting.

Polymeric compositions most often go on sale in finished form. Packing putty at the factory in plastic containers of various capacities. Such material is completely ready for application on walls. When you open the package in a room with room temperature, the finished mixture does not lose its characteristics within 2-3 days.

For the preparation of putty, dry mixes and water are independently used. The ratio of water and powder, as well as the rules for the preparation of the solution are indicated on the package. Manufacturers pack dry mixtures in paper bags of 20 or 25 kg.

When using putty to align the external walls, it should be borne in mind that for these purposes you need to choose an acrylic or polymer-cement mixture, because latex-based material cannot cope with the aggressive external effects of precipitation and temperature changes.

When choosing what is best for leveling walls, you should consider the advantages of polymer compositions:

- universality of application (exception alignment of metal surfaces),

- better adhesion with any bases, in comparison with other types of putties,

- immunity to high humidity,

- lack of bad smell

- polymers allow to obtain surfaces with the highest strength characteristics,

- immunity to temperature jumps,

- lack of shrinkage during the set of strength,

- immunity to the action of chemical compounds,

- the finished solution can be stored for at least 10 hours,

- the mixture contains only environmentally friendly materials,

- does not require special skills when applying, a beginner finisher will cope.

Acrylic

Regardless of the specialization of the brand, this putty is designed for indoor and outdoor use. The range of its use is quite wide due to the universal composition of the mixture based on polymers. This building material perfectly aligns the walls, so it can be used as a finish. The line includes several varieties of mixtures. One of them includes facade materials intended for decoration of external walls and floors.

Moisture-resistant putties are used to prepare for the facing of concrete walls, as well as to smooth wood surfaces.

Latex

The use of latex-based polymer putty is possible exclusively for interior work. This composition is characterized by easy application and distribution over the surface, as well as the absence of any smell. For processing, it is better to purchase dry mixes: they are more economical, cheaper and practically have no residues due to the preparation of individual servings.

Polymer cement

This polymer variety is intended for outdoor use. It is characterized by economical consumption. This is a white material that can be applied in a layer of 2 cm. It is used for surfaces made of brick, concrete, drywall and cement. The composition of this waterproof and elastic raw material includes cement, lime.

To increase adhesion, some masters add PVA glue to it, or even make compositions on their own, including crushed chalk or marble, acrylic varnish, talc, clay and epoxy in the composition. However, not all experiments can be called successful: it is better to buy a finished composition than to lose on the quality of the mixture.

Scope of application

Polymer putty perfectly lays on the base of different materials. It can be used for surfaces from:

- glass

- tree

- plastic

- concrete

- polyfoam (polyurethane foam),

- drywall

- bricks

- galvanized iron.

By scope of application, this material can be:

Each variety is applicable for specific tasks. For example, leveling mixtures are used for roughing. Conditionally finish varieties provide for the application of soil on them, followed by cladding. Universal ones take a little from each type, they cost more, but the quality characteristics are somewhat inferior to specialized counterparts. Special designed for individual base material.

Manufacturers

In today's market, polymer putty is represented by such companies:

- Fibrelastic

- Prospectors

- Pros

- "Found"

- Bolars

- Finish control

- Volma.

Most of the brands presented are marked by positive reviews from ordinary buyers and professional craftsmen. Working with this material is not difficult, as Internet users at construction forums have noted. It is not difficult to level the surface with its help, while the consumption of putty based on polymers is economical if the surface does not have large differences in height.

Selection tips

To choose a high-quality and easy-to-use polymer material, you can take a note several recommendations of experts.

- If you need to process the surface of wood, you should pay attention to the polymer acrylic putty with a wood texture.

- Choose a moisture-resistant variety: it will not deform in rooms with high humidity and will not move away from the surface in case of flooding from a neighboring apartment.

- When choosing a facade variety, pay attention to the indicator of frost resistance. This will extend the use of flooring and facade walls.

- If the amount of work is small, you can buy the finished mixture. With a large repair inside the home, it is better to buy a bag of 25 kg of dry mix for internal work. It is enough to handle problem areas, and you won’t have to think about what to do with the leftovers.

- For facade work, they buy large packages: the area and thickness of the layer in this case are greater, therefore, the material consumption will be large.

- Do not take cheap material: due to the popularity of this composition, it is often faked today.

- Make your purchase in a reputable store with a good reputation and good customer reviews.

Request a certificate of quality and compliance with safety requirements: a self-respecting company always supplies its products with such documentation.

See how to putty walls on your own in the next video.

Comparison of gypsum and polymer putties

A comparative analysis of the characteristics will help determine whether gypsum or polymer putty should be used in specific conditions:

- when using polymer compositions in rooms with high humidity, it should be remembered that this material is not hygroscopic and contributes to the accumulation of moisture on the surface. The gypsum base absorbs excess moisture by adjusting the overall level in the room, but with excessive moisture, the gypsum base is destroyed.

- in terms of vapor permeability, the situation is similar - polymer compositions, unlike gypsum ones, almost do not let pass steam,

- gypsum-based putty is more plastic,

- the environmental safety level of gypsum solutions is higher than polymer ones,

- You can distinguish polymeric materials from gypsum on a perfectly white finished surface. In gypsum mixtures, slight yellowness may be present, and therefore, for important objects, polymer compositions should be chosen,

- the cost of polymeric materials is higher than gypsum.

Drywall

In living rooms and office spaces, standard plaster mixes are usually used for leveling. For the processing of drywall, it is not necessary to apply a starting layer, but before finishing, it is necessary to repair the seams and fastening points of the sheets. Joints embroider at an angle of 45 degrees, paste a sickle and fill with putty.

The use of expensive polymer mixtures is recommended only in rooms with high humidity, where a moisture-proof drywall is mounted.

Concrete

For the alignment of concrete and brick walls and ceilings, any type of mixture can be used, but the operating conditions of the premises should be taken into account. Polymer materials are suitable for rooms with humidity above the norm, and gypsum-based leveling mixtures can be used for rooms with normal humidity.

Latex mixes

If acrylic-based products are a universal solution, this group of putties is suitable only for indoor use. One of the characteristics is the complete absence of any smell. The composition is easy to apply and has a long service life.

The main component in compositions of this type is acrylic. This is a special substance whose characteristics can vary. This polymer interacts well with other components of the mixture. The composition is a homogeneous mass, which after drying forms the most smooth and dense surface.

There are several varieties of similar products. For example, facade putties are most suitable for work on exterior walls and floors. Moisture-resistant putty is used for finishing walls made of concrete, as well as for wooden surfaces.

Depending on the components in the mixture, this building material is divided into starting compositions and finishing. Starting coatings are suitable as a draft to hide serious defects and level changes. Putty polymer finish is necessary only for the final decorative work.

These finishing materials are perfectly applied to any type of surface, but there are also specialized mixtures for wood, concrete, drywall and even metal for sale.

Universal putty is also offered. It is suitable for facade decoration, as well as for interior work. This material is also suitable for floors and various types of surfaces.

Acrylic Putty Recommendations

The drying time of this building material is about 24 hours, however, this figure can vary and depends on the type of mixture and the manufacturer. You can work with this putty only at positive temperatures - in the cold polymer putty loses its elasticity.

Apply the material to the work surface with a thin layer of 1 to 3 mm. If it is necessary to align a sufficiently curved wall, then all layers should be no thicker than 10 mm.

If you need to process wooden surfaces, then acrylic mixtures are perfect for this. One of the characteristics is excellent adhesion with any materials. In addition, the latest types of filler mixtures can mimic the wood texture. If metal work is planned, then it is important to choose the right color.

Work with the material should be the most ordinary spatula. But if you use a solvent and dilute the composition, then you can apply a spray gun. The product is sold fully ready for use.

You can apply these products for both starting and finishing work. It is not recommended to immediately knead the putty with large volumes - the composition quickly thickens and loses its characteristics.

Water dispersion mixtures

The main characteristic is increased resistance to moisture. Moisture-resistant putty dries quickly and has excellent adhesion. These products can be used for finishing work on facades or in rooms with a high level of humidity.

Which is better - gypsum or polymer mixtures?

Today, gypsum compounds are popular as finishing materials. There is nothing surprising here. Gypsum putties have many advantages. They have excellent adhesion, high durability, strength. Minus - the inability to work in wet rooms.

The choice of finishing material depends on what type of work surface you have to process. Plaster products are ideal for plasterboard coatings. For other surfaces it is better to choose polymer compositions - the price is higher, but the quality is higher.

Building mixtures "Hercules"

This company produces a polymer waterproof putty grade GT-73. The mixture is intended for finishing various defects on concrete or cellular concrete surfaces. This product is ideal for both indoor and outdoor use. Polymer putty "Hercules" for wet rooms is especially recommended.

Modern building materials are becoming more technological. Using them is simple, and the quality of the result is very, very high. You should definitely try these polymer blends.